A kind of etching solution composition and etching method of silver-containing composite film

A technology of etching solution and composite film, applied in the direction of surface etching composition, chemical instruments and methods, etc., can solve problems such as adsorption, large difference in rate, ITO collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

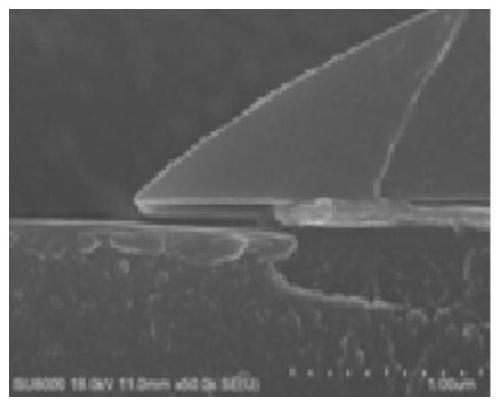

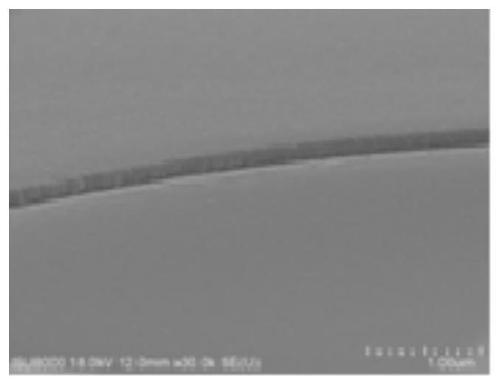

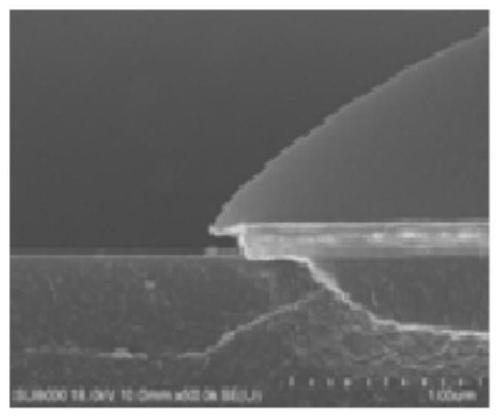

Image

Examples

Embodiment 1-5

[0032] Embodiment 1-5 (embodiment is called for short S, and comparative example is called for short D, hereinafter the same)

[0033] Components in Examples 1-5 and Comparative Examples 1-3 and the percentage by weight of each component are shown in the table below, and the composition of the comparative example etching solution is according to CN107419270A:

[0034] S1 S2 S3 S4 S5 D1 D2 Nitric acid / % 5 8 5.5 6.5 7 6.5 6.5 Phosphoric acid / % 53 47 57 53 50 53 53 Acetic acid% 15 8 5 10 14 10 10 Ammonium acetate / % 0.1 5 2.5 1 2 0 1 Dihydroxybutyric acid / % 0.1 5 0.3 3 1.5 0 0 water / % 26.8 27 29.7 26.5 25.5 30.5 29.5

[0035] Etching experiment:

[0036]Indium oxide film, silver film, and indium oxide film are coated in turn on the substrate to form an ITO-Ag-ITO laminated film, and a photoresist with a predetermined pattern is formed on the substrate by photolithography. In the spray etch...

Embodiment 6-8

[0044] Embodiment 6-8 is based on embodiment 5, and difference is the difference of ammonium salt, and the relation of ammonium salt and ITO residual and etching rate sees the following table:

[0045]

[0046] The etching effect of the etching solution containing ammonium persulfate in the above table is better than the etching solution containing ammonium acetate, diammonium hydrogen phosphate and ammonium sulfate.

Embodiment 9

[0048] Example 9 is based on Example 5 with the difference that an alpha-hydroxy acid is added:

[0049]

[0050] The data in the above table shows that, compared with branched aliphatic hydrocarbon α-hydroxy acids, straight-chain aliphatic hydrocarbon hydroxy acids have a stronger effect on reducing the silver etching rate. In addition, according to the observation results of silver resorption, the silver resorption amount of S6 is ≤25 , lower than the silver resorption of S7 and S8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com