Optical temperature measuring material with color-change fluorescence, and preparation method and application thereof

An optical temperature measurement and fluorescence technology, which is applied in the field of fluorescent color-changing optical temperature measurement materials and its preparation, can solve the problems of unsatisfactory effect and poor energy level, and achieve the effects of stable properties, wide temperature measurement range and high relative sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh calcium carbonate (CaCO 3 ) 3.0006g, lithium carbonate (Li 2 CO 3 ) 0.3695g, ammonium metavanadate (NH 4 VO 3 ) 3.5093g, zinc oxide (ZnO) 0.8141g, and europium oxide (Eu 2 o 3 ) 0.0035g, the above-mentioned raw materials are fully ground and mixed in a mortar, then placed in a corundum crucible, baked in a high-temperature furnace at 1000 ° C for 2 hours, cooled to room temperature, taken out, and after grinding and dispersing, the composition is Ca 2.998 Sr 0.00 ZnLi(VO 4 ) 3 :Eu 0.002 3+ optical temperature measurement materials.

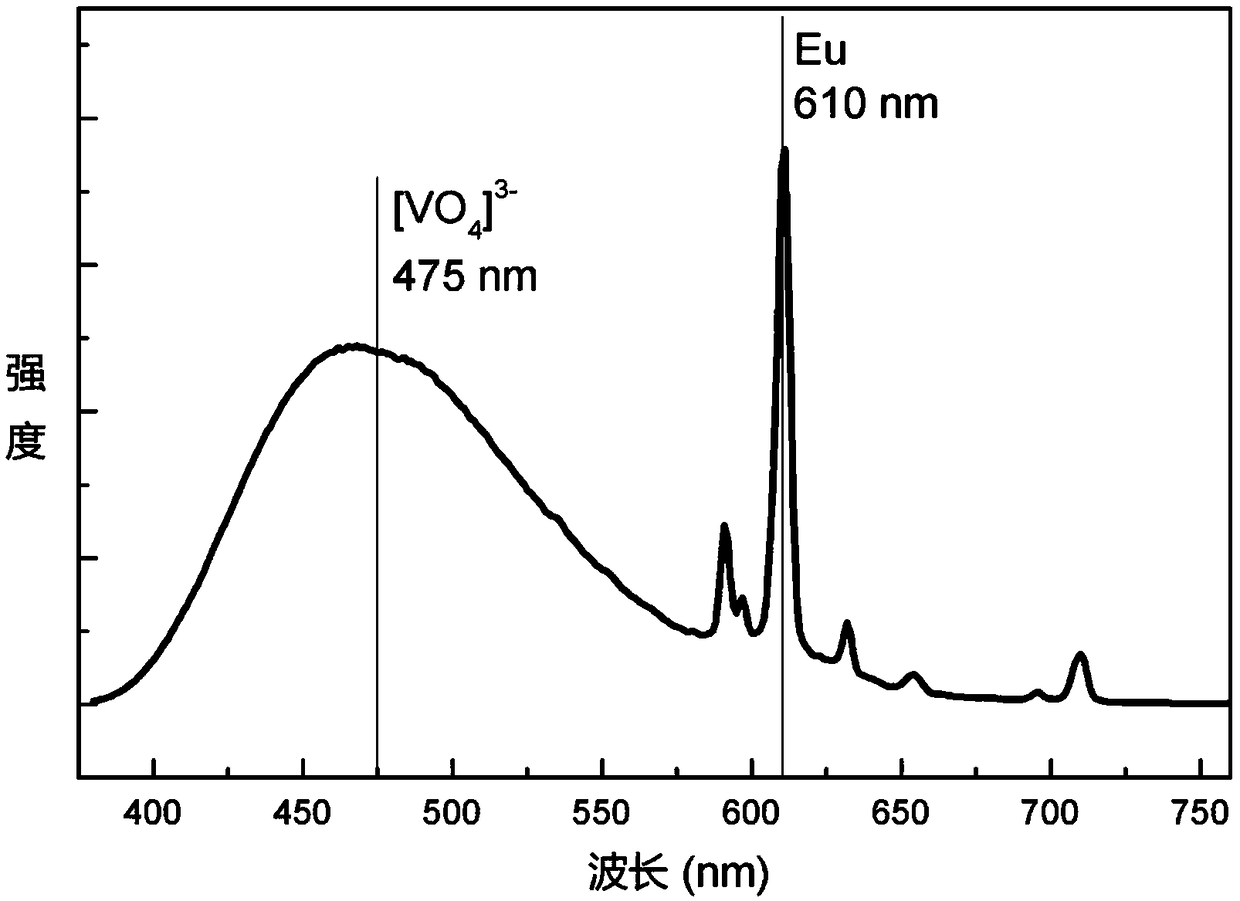

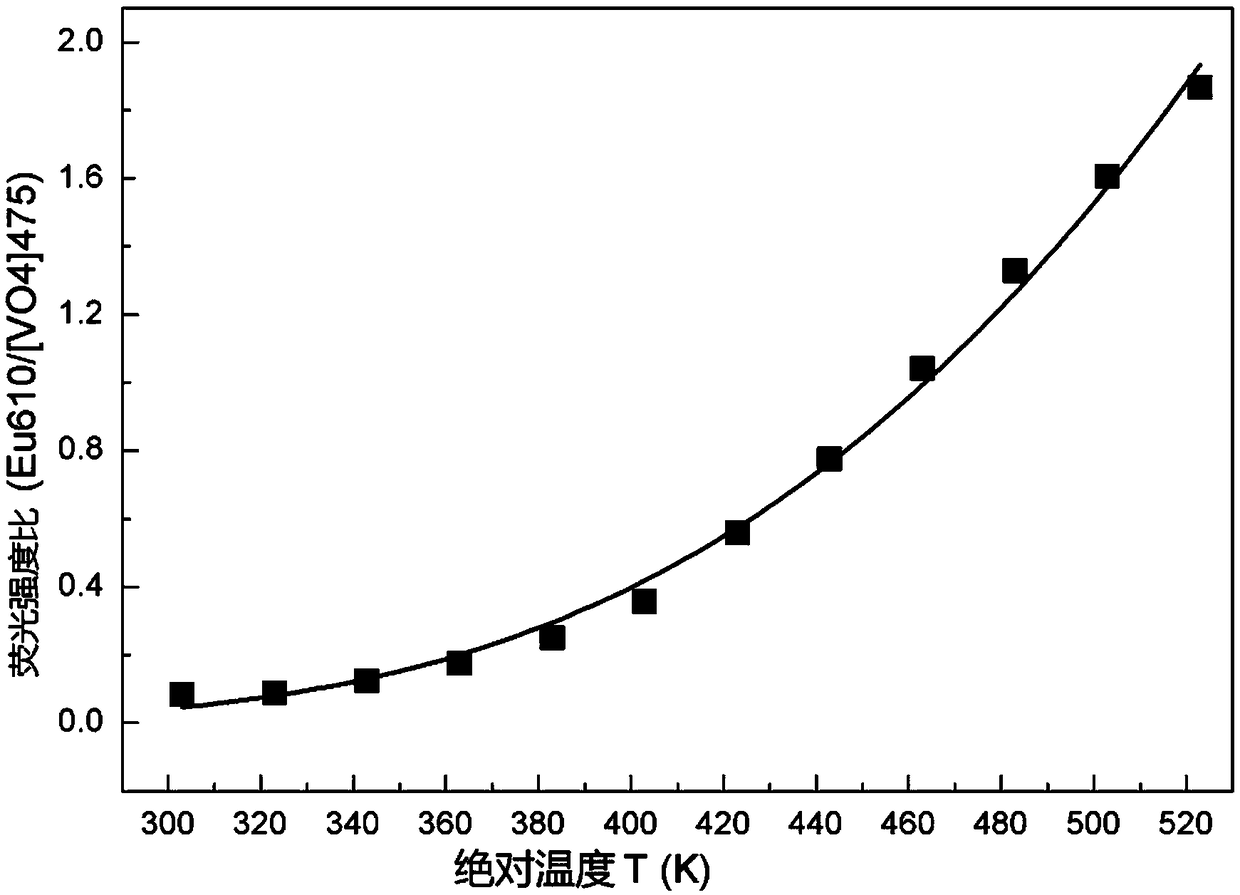

[0031] Excitation and emission tests were carried out on the optical temperature measurement material with a Hitachi F-7000 fluorescence spectrometer, and a 150W xenon lamp was used as the excitation light source. The results show that the material has good absorption in the ultraviolet light band and can be effectively excited by ultraviolet light . Under the effective excitation of ultraviolet light, the [VO 4 ] 3- gro...

Embodiment 2

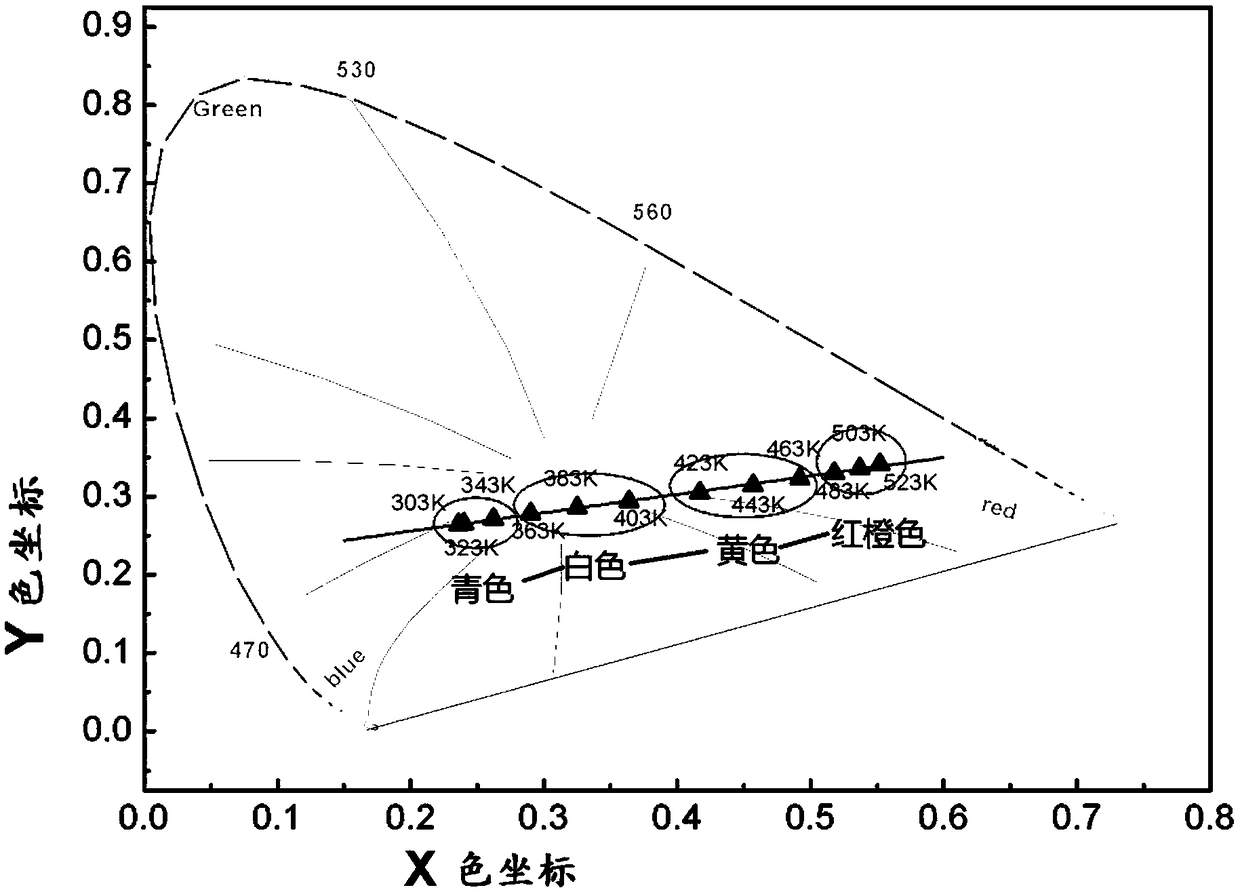

[0033] Weigh respectively calcium oxide (CaO) 1.6795g, lithium oxide (Li 2 O) 0.1494g, vanadium pentoxide (V 2 o 5 ) 2.7282g, zinc hydroxide (Zn(OH) 2 )0.9942g, and europium oxide (Eu 2 o 3 ) 0.0088g, the above-mentioned raw materials were fully ground and mixed in a mortar, then placed in a corundum crucible, baked in a high-temperature furnace at 900°C for 3 hours, cooled to room temperature, taken out, and after grinding and dispersing, the composition Ca 2.995 Sr 0.00 ZnLi(VO 4 ) 3 :Eu 0.005 3+ optical temperature measurement materials. In this way, the temperature can be roughly qualitatively calibrated by using the fluorescence color change, and the temperature can be precisely quantitatively calibrated by using the fluorescence intensity ratio.

Embodiment 3

[0035] Weigh calcium hydroxide (Ca(OH) 2 ) 2.2172g, lithium hydroxide (LiOH) 0.2395g, ammonium metavanadate (NH 4 VO 3 ) 3.5093g, zinc carbonate (ZnCO 3 ) 1.2542g, and europium oxide (Eu 2 o 3 ) 0.0132g, the above-mentioned raw materials were fully ground and mixed in a mortar, then placed in a corundum crucible, baked in a high-temperature furnace at 800°C for 4 hours, cooled to room temperature, taken out, and after grinding and dispersing, the composition Ca 2.9925 Sr 0.00 ZnLi(VO 4 ) 3 :Eu 0.0075 3+ optical temperature measurement materials. In this way, the temperature can be roughly qualitatively calibrated by using the fluorescence color change, and the temperature can be precisely quantitatively calibrated by using the fluorescence intensity ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com