Mesa-type photodetector with low surface leakage current and manufacturing method thereof

A technology for photodetectors and manufacturing methods, which is applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as difficulties in passivating sidewall surfaces, and achieve the goals of protecting the surface of the sulfide layer, improving long-term stability, and improving surface adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The manufacturing method of a low surface leakage current mesa photodetector of the present invention can be realized according to the following scheme:

[0036] (1) Define the mesa etching window, deposit a mask on the top layer of the epitaxial wafer, and open the mesa etching window through the photolithography process;

[0037] (2) The epitaxial wafer is etched into a platform by wet etching, and then the surface is chemically cleaned to remove residual products of the wet etching reaction, surface oxides, and surface impurities.

[0038] (3) Adopt sulfuration process to passivate the side wall surface and reduce its surface state.

[0039] (4) Treat the surface with hexamethyldisilamine (HMDS) to enhance adhesion, and then coat BCB. Under the protection of N2 atmosphere, it is cured by distributed temperature rise.

[0040] (5) Define the P electrode, deposit the metal film by evaporation or sputtering, and form the P electrode pattern after stripping.

[0041] ...

Embodiment 2

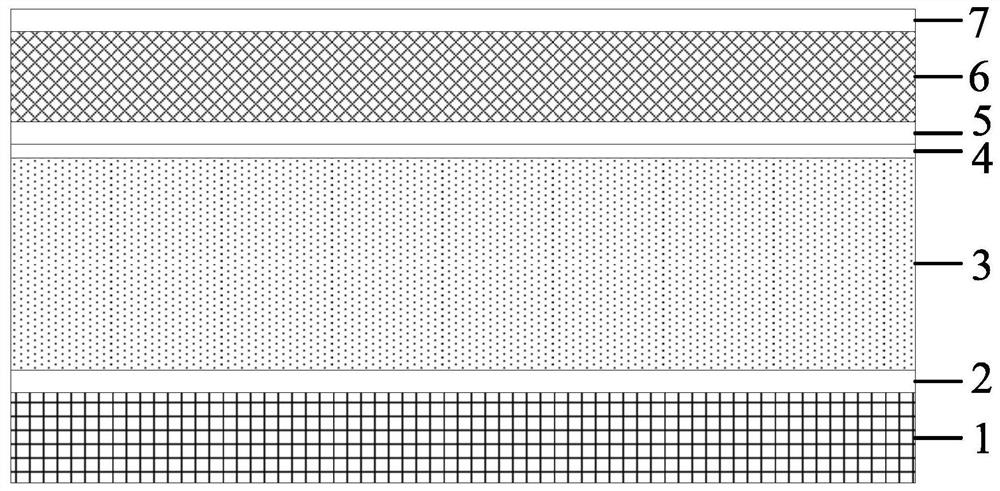

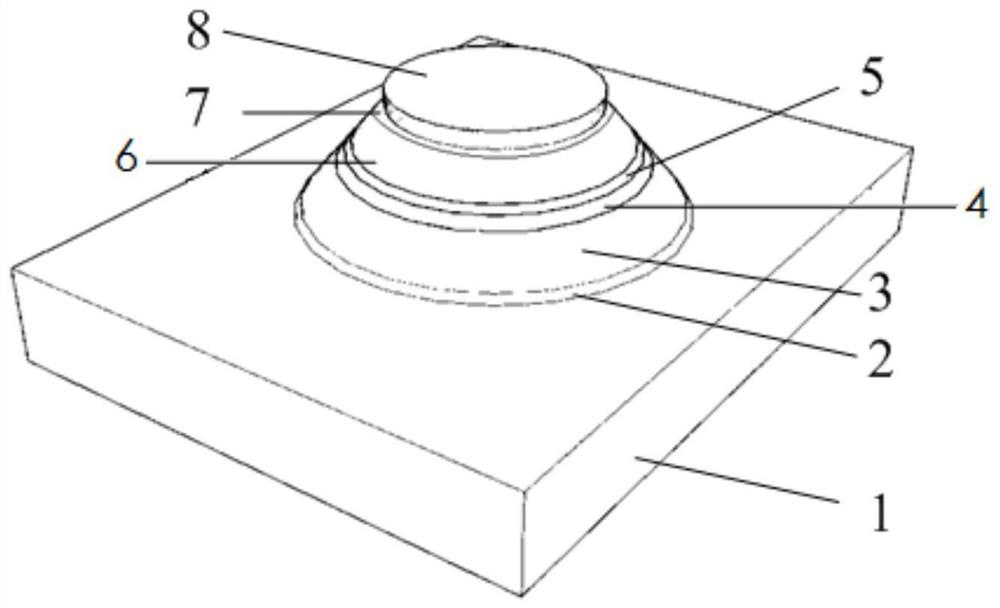

[0049] On the basis of Embodiment 1, this embodiment takes the mesa manufacturing process of avalanche photodiode as a column, and its epitaxial wafer structure is as follows figure 1 Shown includes: N-type InP substrate 1; N-type InP buffer layer 2 with a thickness of 0.1-1 μm and a doping concentration of less than 8×10 17 cm -3 ; Non-doped-InGaAs absorption layer 3, thickness 1-3 μm; N-type InGaAsP gradient layer 4, thickness 0.01-0.1 μm, doping concentration less than or equal to 1×10 17 cm -3 ; The N-type InP charge layer 5 has a thickness of 0.1-0.5 μm and a doping concentration of 5×10 16 ~5×10 17 cm -3 ; InP multiplication layer 6, P-type-InGaAsP contact layer 7, thickness 0.05-0.1 μm, doping concentration greater than 1×10 19 cm -3 .

[0050] Concrete preparation process is as follows:

[0051] (11) Using plasma enhanced chemical vapor deposition (PECVD), grow a layer of SiNx / SiO 2 / SiNx composite dielectric film 8 is spin-coated with photoresist through a ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com