Catalyst for directly converting syngas to prepare low-carbon olefin, and preparation method and application thereof

A low-carbon olefin and synthesis gas technology, which is applied in catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc. The effect of saving equipment investment and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

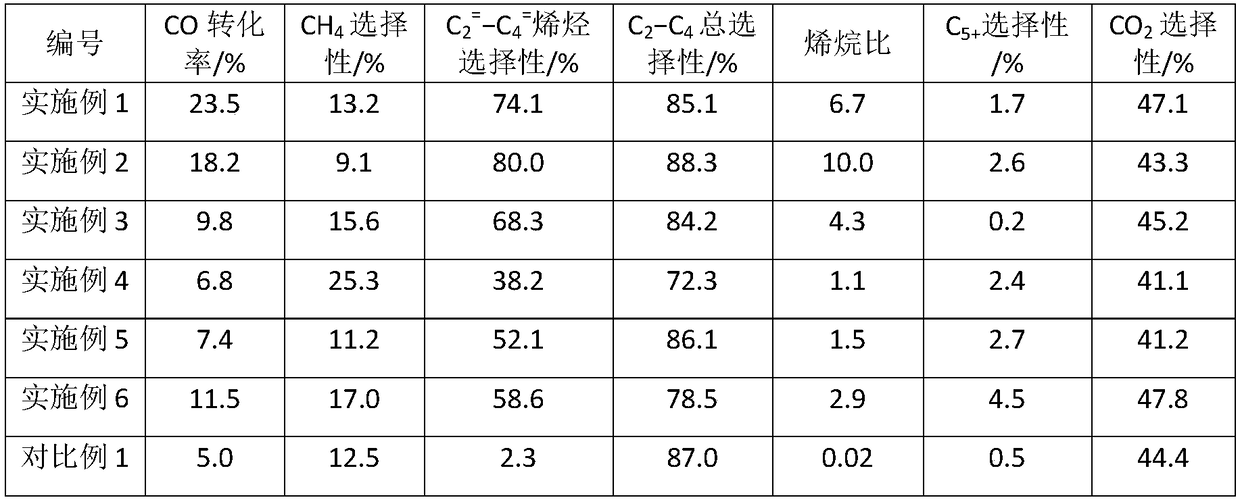

Examples

Embodiment 1

[0027] Composite metal oxide catalyst MO x -ZnO-NO y preparation. Weigh 26.84 parts of manganese nitrate (50% aqueous solution), 7.45 parts of zinc nitrate hexahydrate, and 0.03 parts of silver nitrate in distilled water to prepare a 1.0mol / L aqueous solution, and use sodium carbonate as a precipitating agent to prepare a 1.0mol / L solution Co-precipitation reaction occurs by co-current dripping method. By controlling the drop rate, the pH during the precipitation process is 7.0±0.2, the precipitation temperature is controlled at 30°C, and the titrated precipitate is aged at 30°C for 2 hours. The aged product The precipitate was washed with deionized water, dried at 80°C, and then baked in a muffle furnace at 450°C for 5h. Gained catalyst mass percentage is composed of: MnO 2 76.0%, ZnO 23.7%, Ag 2 O 0.3%.

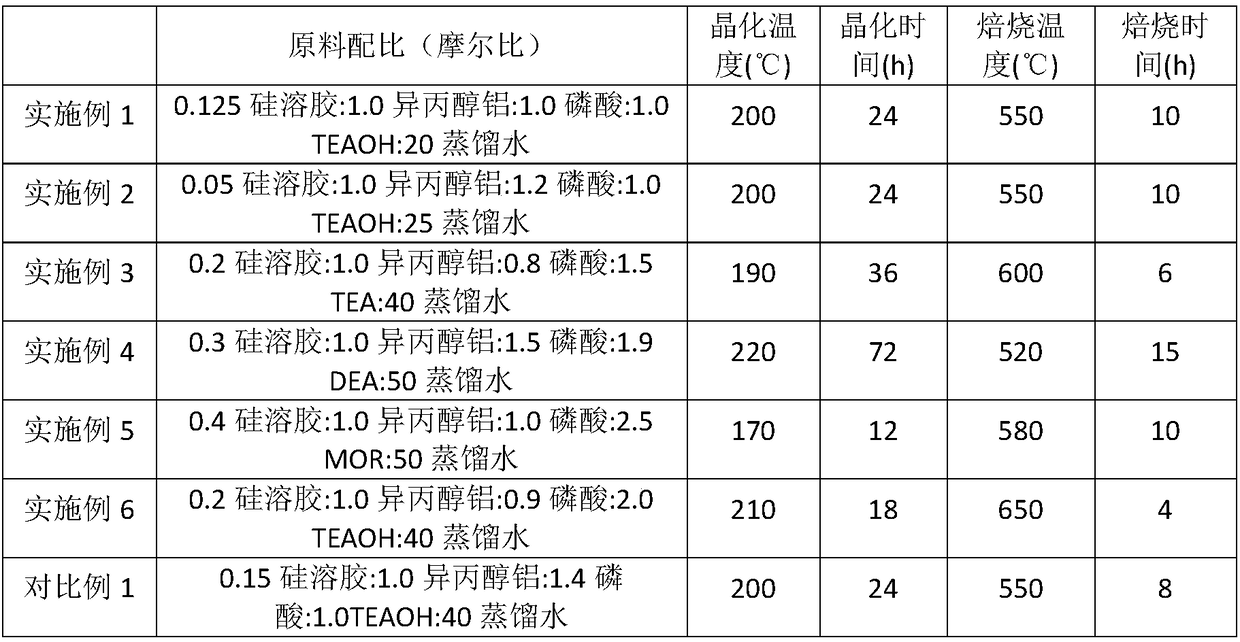

[0028]Preparation of SAPO-34 molecular sieve catalyst (see attached table 1 for catalyst preparation parameter conditions). Weigh 30.08 parts by mass fraction of 35%...

Embodiment 2

[0032] Composite metal oxide catalyst MO x -ZnO-NO y preparation. Take by weight 29.83 parts of manganese nitrate (50% aqueous solution), 4.94 parts of zinc nitrate hexahydrate, and 0.03 parts of potassium nitrate dissolved in distilled water to prepare a 1.0mol / L aqueous solution, and use sodium carbonate as a precipitating agent to prepare a 1.0mol / L solution Co-precipitation reaction occurs by co-current dripping method, the pH of the precipitation during the precipitation process is controlled by controlling the dropping speed=7.5±0.2, the precipitation temperature is controlled at 40°C, and the titrated precipitate is aged at 40°C for 5h. The product was washed and precipitated with deionized water, dried at 80°C, and then baked in a muffle furnace at 420°C for 5h. Gained catalyst mass percentage is composed of: MnO 2 84.1%, ZnO15.7%, K 2 O 0.2%.

[0033] The preparation of SAPO-34 molecular sieve catalyst (catalyst preparation parameter conditions see attached tabl...

Embodiment 3

[0036] Composite metal oxide catalyst MO x -ZnO-NO y preparation. Weigh 28.64 parts of zirconium nitrate pentahydrate, 9.91 parts of zinc nitrate hexahydrate, 0.13 parts of lanthanum nitrate hexahydrate and dissolve in distilled water to prepare a 1.0mol / L aqueous solution, and use ammonia as a precipitating agent to prepare a 1.0mol / L aqueous solution , Co-precipitation reaction occurs by co-current dropping method, the precipitation pH is controlled by controlling the dropping speed = 8, the precipitation temperature is controlled at 45°C, the titrated precipitate is aged at 45°C for 3h, and the aged product is washed and precipitated with deionized water , after drying at 80 ° C, placed in a muffle furnace at 500 ° C for 5 hours. Gained catalyst mass percentage is composed of: ZrO 2 74.9%, ZnO 24.7%, La 2 o 3 0.4%.

[0037] The preparation of SAPO-34 molecular sieve catalyst (catalyst preparation parameter conditions see attached table 1), the specific preparation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com