Styrene-butadiene emulsion and preparation method thereof

A styrene-butadiene emulsion and dispersion technology, which is applied in papermaking, coating, pigmented coating, etc., can solve the problems of bond strength and water resistance to be improved, and achieve the effect of improving the bond and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

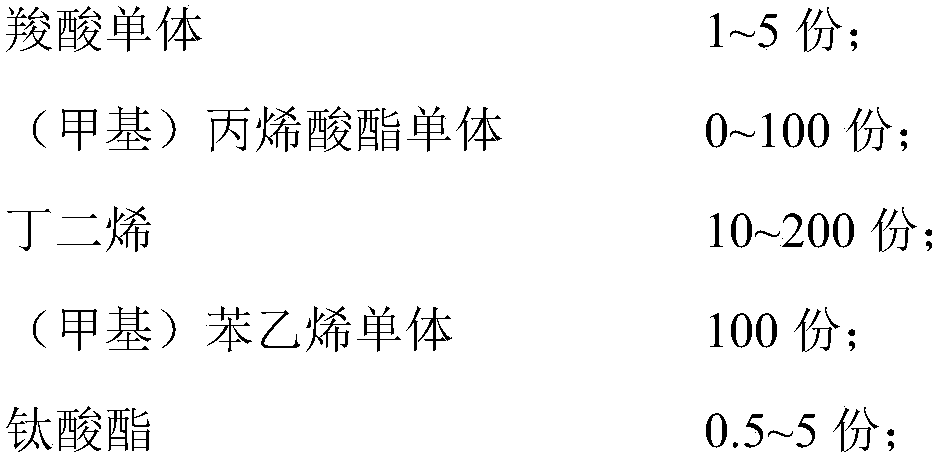

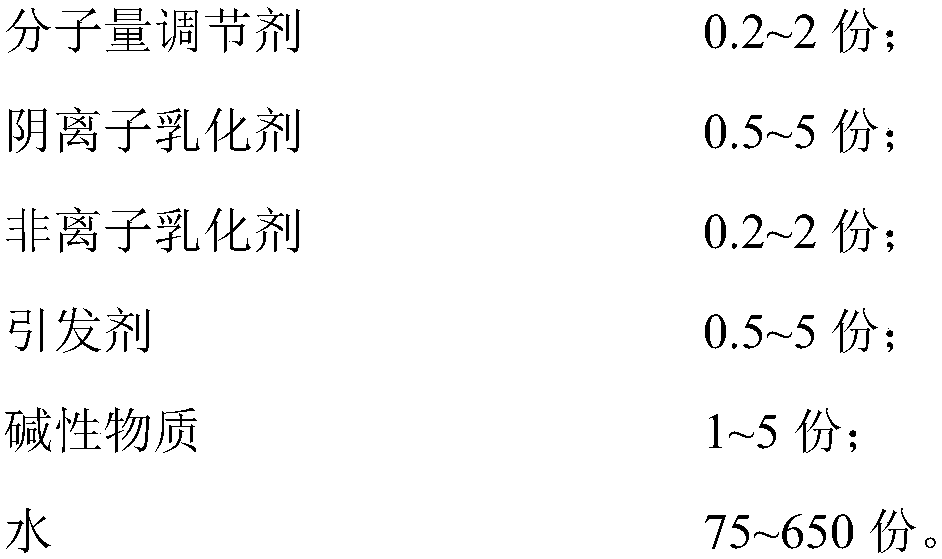

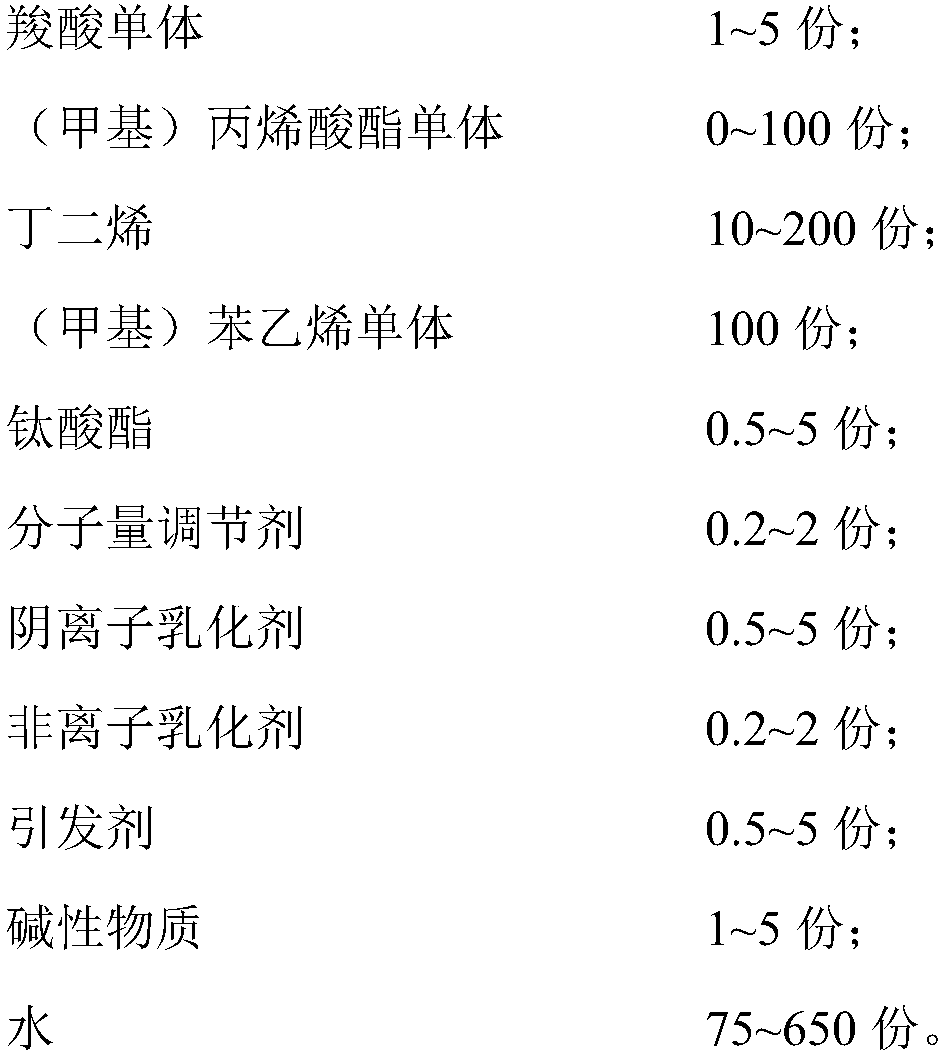

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of styrene-butadiene emulsion base material:

[0040] The 2000ml pressurized reaction kettle is first evacuated, and the vacuum degree is -0.095MPa. Add 0.1g of sodium lauryl sulfate, 0.1g of potassium persulfate, and 50g of distilled water to completely dissolve into an aqueous solution. Start stirring and heat up to 60°C. At the same time, 1 g of acrylic acid, 10 g of butadiene, 100 g of styrene, 0.2 g of n-dodecyl mercaptan, and 0.5 g of n-butyl titanate were added dropwise at 60°C; and 0.4 g of dodecyl A mixed aqueous solution of sodium sulfate, 0.2 g of polyoxyethylene (20) sorbitan monooleate (Tween 80), 0.4 g of potassium persulfate, and 21.93 g of distilled water. The dropwise addition time was 6 hours. After the dropwise addition was completed, the temperature was kept at 60° C. for 4 hours. Cool to 25° C., and neutralize with 5 grams of 20 wt % sodium hydroxide aqueous solution. Filter through a 100-mesh sieve to obtain a styrene-butadiene em...

Embodiment 2

[0046] 1. Preparation of styrene-butadiene emulsion base material:

[0047] The 2000ml pressurized reaction kettle is first evacuated, and the vacuum degree is -0.095MPa. Add 2 grams of sodium dodecyl naphthalene sulfonate, 1 gram of sorbitan monooleate (Span 80), 1 gram of sodium persulfate, 500 1 g of distilled water and 5 g of styrene were completely dissolved into an aqueous solution, and the stirring was started, and the temperature was raised to 90°C. At the same time, 5 grams of methacrylic acid, 50 grams of n-butyl acrylate, 50 grams of methyl methacrylate, 200 grams of butadiene, 95 grams of methyl styrene, and 2 grams of tert-dodecyl mercaptan were added dropwise at 90°C. 2 grams of n-butyl titanate, a mixed monomer of 3 grams of isopropyl trioleate acyloxy titanate; and 3 grams of sodium dodecyl naphthalene sulfonate, 1 gram of sorbitan monolaurate ( Span 20), 4 grams of sodium persulfate, a mixed aqueous solution of 111 grams of distilled water. The dropwise addi...

Embodiment 3

[0053] 1. Preparation of styrene-butadiene emulsion base material:

[0054] The 2000ml pressurized reaction kettle is first evacuated, and the vacuum degree is -0.095MPa. Add 0.5 grams of sodium lauryl sulfate, 0.5 grams of ammonium persulfate, 150 grams of distilled water, and 2 grams of styrene to completely dissolve into an aqueous solution. Start stirring and heat up to 80°C. At the same time, 3 grams of methacrylic acid, 100 grams of butadiene, 98 grams of styrene, 1 gram of n-dodecanethiol, and 0.5 grams of isopropyl tris(dioctyl pyrophosphate acyloxy)titanium were added dropwise at 80°C. ester, 2 grams of bis(dioctyloxypyrophosphate) ethylene titanate mixed monomer; and 2 grams of sodium dialkyl-2-sulfosuccinate, 1.5 grams of polyoxypropylene stearate , 2 grams of ammonium persulfate, a mixed aqueous solution of 59 grams of distilled water. The dropwise addition time was 4 hours. After the dropwise addition was completed, the temperature was kept at 80° C. for 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com