A high-capacity silicon-carbon negative electrode active material and its preparation method and application

A technology of negative electrode active materials and silicon carbon materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of poor cycle performance, complex preparation process and high cost of high capacity silicon carbon negative electrode active materials, and achieve the promotion of industrialization The process and process are simple and the effect of not easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

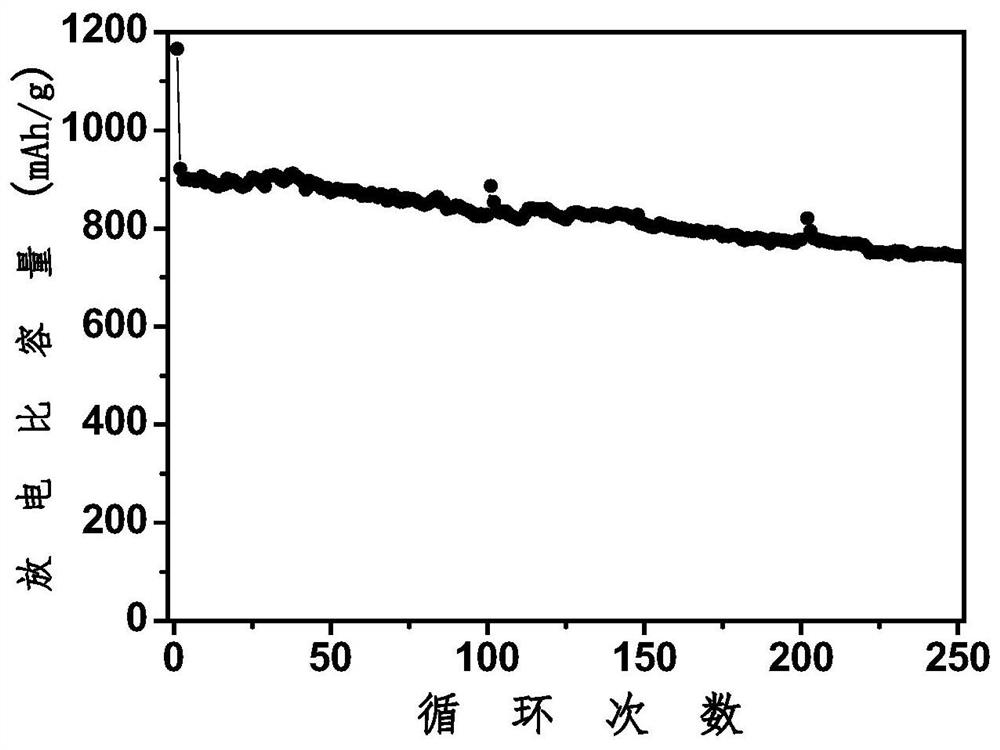

Embodiment 1

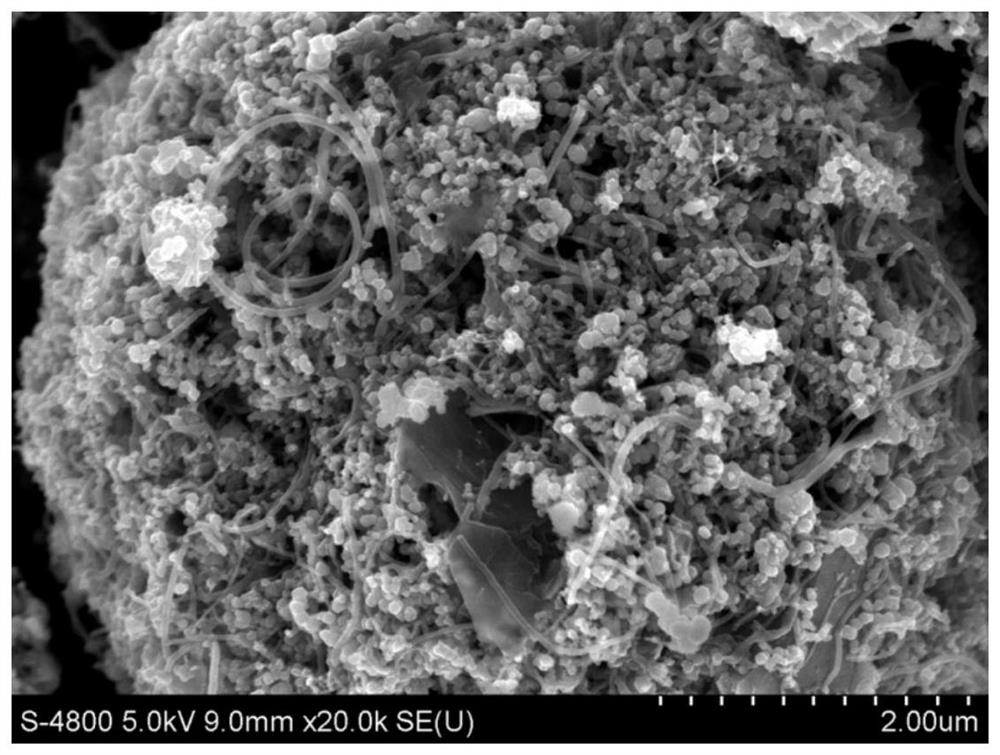

[0036] Material Synthesis:

[0037] (1) Ball mill silicon with a particle size of 80nm, flake graphite with a length of 10um and a thickness of 10nm, carbon nanotubes with a diameter of 5nm and a diameter of 60-100um, pitch and polyvinylpyrrolidone in ethylene glycol for 5 hours , with a rotational speed of 300rpm; wherein, the mass ratio of silicon, graphite, carbon nanotubes, and pitch pyrolytic carbon is 70:10:5:15; the mass ratio of silicon to polyvinylpyrrolidone is 100:3;

[0038] (2) Dilute the ball-milled slurry to a solid content of 25%, ultrasonicate at 5°C for 30min, with an ultrasonic power of 1300W, and then stir for 5h at a speed of 500rpm;

[0039] (3) Use two-fluid spray equipment for granulation, and the inlet and outlet temperatures are set to 250 and 120°C respectively;

[0040] (4) the product obtained by spraying in N 2 Heat treatment in the atmosphere, 480°C for 2h + 850°C for 3h, to prepare silicon carbon material A.

[0041] (5) Mix the prepared silico...

Embodiment 2

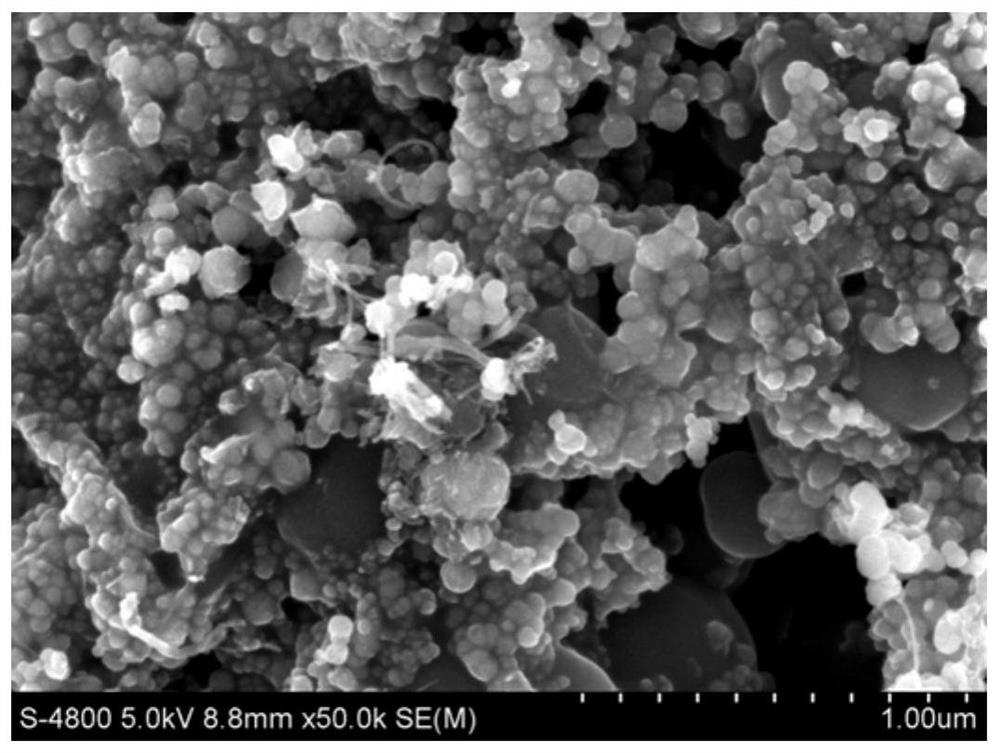

[0047] Material Synthesis:

[0048] (1) Silicon with a particle size of 50nm, flake graphite with a length of 10-20um and a thickness of 60nm, carbon nanotubes with a width and diameter of 50nm and 20um, carbon source and sodium dodecylsulfonate Ball milling was carried out in ethanol at a speed of 2000rpm, and the ball milling time was 0.2h; wherein, the mass ratio of silicon, graphite, carbon nanotubes, and carbon source pyrolytic carbon was 55:5:8:32; the ratio of silicon to sodium dodecylsulfonate The mass ratio is 100:15; the carbon source in the carbon source pyrolytic carbon is a mixture of polyimide and polyvinyl butyral in any proportion;

[0049] (2) Adjust the solid content of the slurry after ball milling to 40%, and after ultrasonication for 30 minutes, stir for 0.5 hour at a speed of 2000 rpm;

[0050] (3) Use spray equipment to granulate, and the inlet and outlet temperatures are set to 150 and 90°C respectively;

[0051] (4) the product obtained by spraying i...

Embodiment 3

[0057] Material Synthesis:

[0058] (1) Silicon with a particle size of 150nm, flake graphite with a length of 8-10um and a thickness of 40nm, carbon nanotubes with a diameter width and diameter of 8-15nm and 30um, sucrose pyrolytic carbon and triton Carry out ball milling in acetone, rotating speed 1000rpm, ball milling time 2h; Wherein, the mass ratio of silicon, graphite, carbon nanotube, sucrose pyrolytic carbon is 40:10:10:40; The mass ratio of silicon and triton is 100: 5;

[0059] (2) adjust the solid content of the slurry after ball milling to 30%, after ultrasonication for 30min, stir for 3h, and the stirring speed is 1000rpm;

[0060] (3) Use spray equipment to granulate, and the inlet and outlet temperatures are 160 and 70°C respectively;

[0061] (4) the product obtained by spraying in N 2 Heat treatment is carried out in the atmosphere, the temperature is 600° C., and the treatment time is 6 hours, and the silicon carbon material A is obtained.

[0062] (5) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com