MoO3 composite carbon-dot lithium-ion battery anode material and preparation method thereof

A technology for lithium-ion batteries and anode materials, applied in the field of MoO3 composite carbon-dot lithium-ion battery anode materials and its preparation, can solve problems such as poor cycle performance and low conductivity, and achieve excellent conductivity, high yield and low energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1), adding performic acid as an oxide to coal tar pitch and centrifuging for 24 hours, then taking the supernatant, which is a carbon dot solution in which the solvent is performic acid;

[0023] 2), get 0.325g analytically pure ammonium molybdate ((NH 4 )Mo 7 o 24 4H 2 0) put into beaker, then add 10ml deionized water, ultrasonic 10min, make ammonium molybdate dissolve completely and disperse evenly;

[0024] 3) Take 15ml of the carbon dot solution and add it to the above solution, mix well, put it into the polytetrafluoroethylene lining, and conduct a hydrothermal reaction at 180°C for 6h;

[0025] 4) After the hydrothermal kettle was naturally cooled to room temperature, it was washed with deionized water and absolute ethanol for more than three times, and dried in vacuum for 12 hours to prepare MoO 3 Composite carbon dot lithium ion battery anode material.

Embodiment 2

[0027] 1), adding performic acid as an oxide to coal tar pitch and centrifuging for 24 hours, then taking the supernatant, which is a carbon dot solution in which the solvent is performic acid;

[0028] 2), get 0.45g analytically pure ammonium molybdate ((NH 4 )Mo 7 o 24 4H 2 0) put into beaker, then add 10ml deionized water, ultrasonic 10min, make ammonium molybdate dissolve completely and disperse evenly;

[0029] 3) Take 30ml of carbon dot solution and add it to the above solution and mix well, then put it into the polytetrafluoroethylene lining, and react with hydrothermal reaction at 120°C for 24h;

[0030] 4) After the hydrothermal kettle was naturally cooled to room temperature, it was washed with deionized water and absolute ethanol for more than three times, and dried in vacuum for 20 hours to prepare MoO 3 Composite carbon dot lithium ion battery anode material.

Embodiment 3

[0032] 1), adding performic acid as an oxide to coal tar pitch and centrifuging for 24 hours, then taking the supernatant, which is a carbon dot solution in which the solvent is performic acid;

[0033]2), get 0.55g analytically pure ammonium molybdate ((NH 4 )Mo 7 o 24 4H 2 0) put into beaker, then add 10ml deionized water, ultrasonic 10min, make ammonium molybdate dissolve completely and disperse evenly;

[0034] 3) Take 45ml of carbon dot solution and add it to the above solution and mix well, then put it into the polytetrafluoroethylene lining, and react with hydrothermal reaction at 150°C for 15h;

[0035] 4) After the hydrothermal kettle was naturally cooled to room temperature, it was washed with deionized water and absolute ethanol for more than three times, and dried in vacuum for 24 hours to prepare MoO 3 Composite carbon dot lithium ion battery anode material.

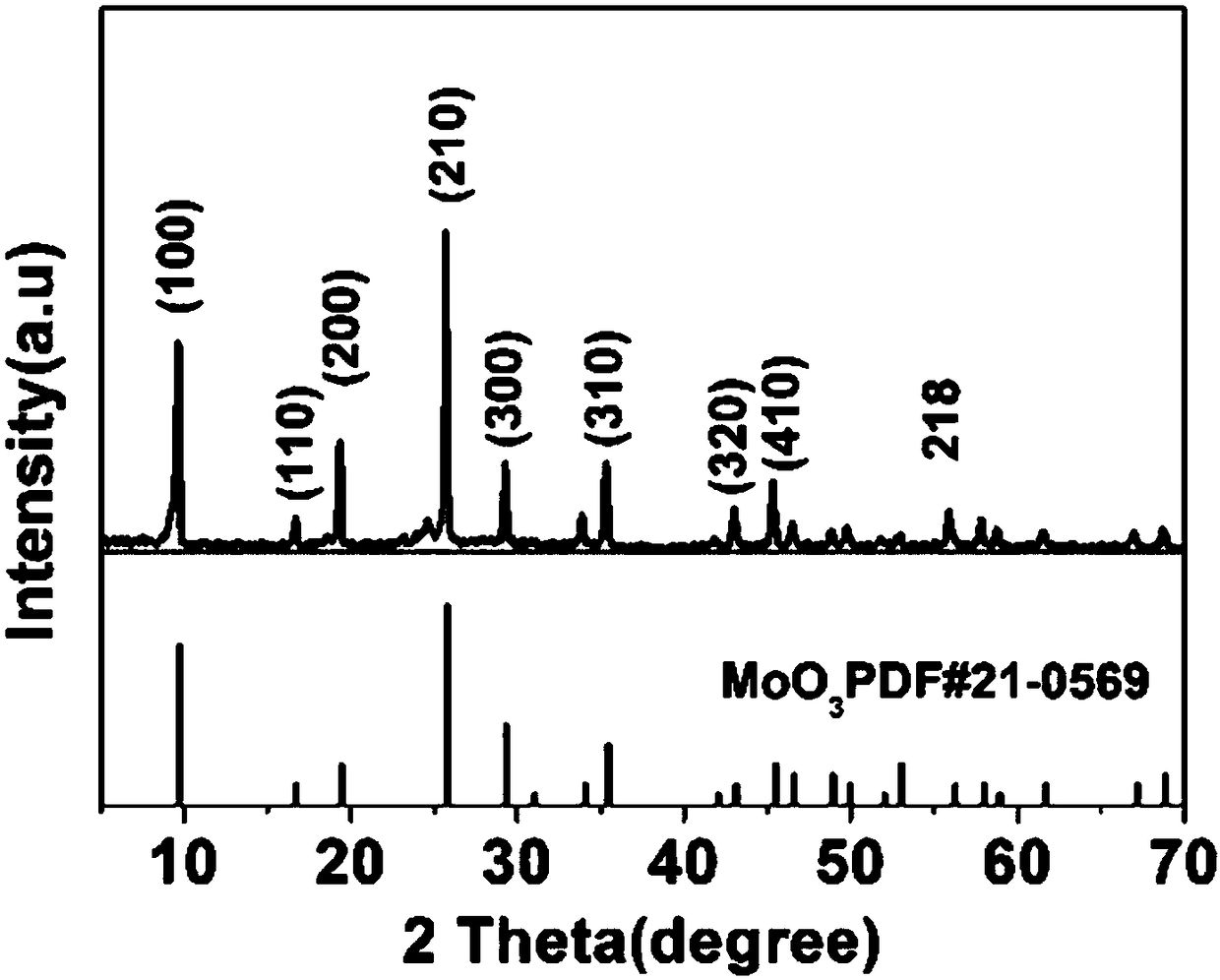

[0036] see figure 1 , it can be seen that the prepared product is h-MoO 3 , compared with the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com