Semen myristicae essential oil microcapsules as well as preparation method and application thereof

A technology of nutmeg essential oil and microcapsules is applied in the directions of microcapsule preparations, microsphere preparation, microcapsules, etc., and can solve problems such as adverse effects on product quality, product particle size, fluidity, encapsulation rate, and insufficient retention rate of essential oils. , to achieve the effect of improving the encapsulation rate and retention rate, concentrating the particle size distribution range, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

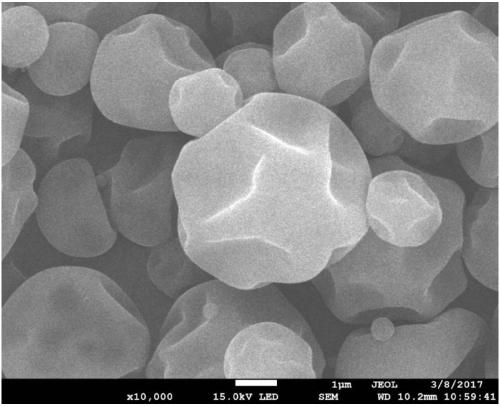

[0045] Example 1: Preparation of nutmeg essential oil microcapsules of the present invention

[0046] 1) Selection of raw materials: select 16.2 g of starch octenyl succinate, 10.8 g of inulin, and 8.0 g of nutmeg essential oil for use;

[0047] 2) Preparation of emulsion: Dissolve starch octenyl succinate in water, add 2.7 g of inulin under magnetic stirring, and after fully dissolving, cool to room temperature, add essential oil, high-speed shear, and homogenize to obtain a homogeneous emulsion;

[0048] The conditions of the magnetic stirring are: 300rpm, 50°C;

[0049] The high-speed shearing conditions are: 10000rpm, 60s;

[0050] The conditions of homogenization are: 60mbar, 2 cycles;

[0051] 3) Preparation of microcapsules: granulate by emulsion boiling drying method, set appropriate feed rate, maintain feed temperature and outlet temperature, add remaining 8.1g inulin as granulation material to obtain nutmeg essential oil microcapsules;

[0052] The conditions of the boiling dryi...

Embodiment 2

[0054] Example 2: Preparation of nutmeg essential oil microcapsules of the present invention

[0055] 1) Selection of raw materials: 10g of starch octenyl succinate, 10g of inulin, and 10g of nutmeg essential oil are selected for use;

[0056] 2) Preparation of emulsion: Dissolve starch octenyl succinate in water, add 2.5 g of inulin under magnetic stirring, and after fully dissolving, cool to room temperature, add essential oil, high-speed shear, and homogenize to obtain a homogeneous emulsion;

[0057] The conditions of the magnetic stirring are: 500rpm, 60℃;

[0058] The conditions of the high-speed shearing are: 8000rpm, 80s;

[0059] The conditions of homogenization are: 40mbar, 3 cycles;

[0060] 3) Preparation of microcapsules: granulate by emulsion boiling drying method, set appropriate feed speed, maintain feed temperature and outlet temperature, add the remaining 7.5g inulin as granulation material to obtain nutmeg essential oil microcapsules;

[0061] The conditions of the boil...

Embodiment 3

[0063] Example 3: Preparation of nutmeg essential oil microcapsules of the present invention

[0064] 1) Selection of raw materials: select 14.5 g of starch octenyl succinate, 9.7 g of inulin, and 10.9 g of nutmeg essential oil for use;

[0065] 2) Preparation of emulsion: Dissolve starch octenyl succinate in water, add 2.4 g of inulin under magnetic stirring, after fully dissolving, cool to room temperature, add essential oil, high-speed shear, and homogenize to obtain a homogeneous emulsion;

[0066] The conditions of the magnetic stirring are: 300rpm, 40°C;

[0067] The high-speed shearing condition is: 10000rpm, 30s;

[0068] The conditions of homogenization are: 60mbar, 2 cycles;

[0069] 3) Preparation of microcapsules: granulate by emulsion boiling and drying method, set appropriate feed speed, maintain feed temperature and outlet temperature, add remaining 7.3g inulin as granulation material to obtain nutmeg essential oil microcapsules;

[0070] The conditions of the boiling dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com