A kind of carbon nanocomposite wave-absorbing slurry and preparation method thereof

A carbon nanocomposite and carbon nanotechnology, applied in the direction of radiation-absorbing coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as limitations in direct application fields, solve dispersion and functional application problems, and improve electromagnetic Protective performance, the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of carbon nano wave-absorbing slurry, comprising the following steps:

[0030] S1. Put the polyols and additives in acetone in sequence, and use mechanical stirring or magnetic stirring at a temperature of 30-40° C. at a rotation speed of 100-500 r / min, and stir until fully fused to obtain the first mixture;

[0031] S2. At a temperature of 40-50°C, add the nano-carbon material into the first mixture of S1, disperse and mix for 30-90min, and rotate at a speed of 500-1000r / min to prepare the second mixture;

[0032] S3. At a temperature of 50-60°C, add isocyanate into the second mixture of S2, and keep it warm for 30-60min; at a temperature of 60-65°C, keep it warm for 60-100min; the third mixture;

[0033] S4. At a temperature of 60-65° C., adding ferrite materials into the third mixture of S3 to prepare a fourth mixture;

[0034] S5. At a temperature of 50-60° C., add distilled water and adjust the pH to 6-7 with hydrochloric acid or sodium hydro...

Embodiment 2

[0043] S1. Put 5-10ml of acetone in a four-necked flask with a volume of 500ml, connected with mechanical stirring, condensing reflux, thermometer, nitrogen protection and a liquid filling port, and successively add 100g-110g of polyester diol, 0.015-0.08g of fat The emulsifier compounded with alcohol polyoxyethylene ether and 0.005-0.02g sodium dodecylbenzenesulfonate, the flame retardant compounded with 5-10g aluminum hydroxide and 3-8g trimethyl phosphate are dissolved in a four-necked flask in a fume hood, mechanically stirred at a speed of 100-500r / min, and a temperature of 30-40°C, so that the components are fully fused to obtain the first mixture;

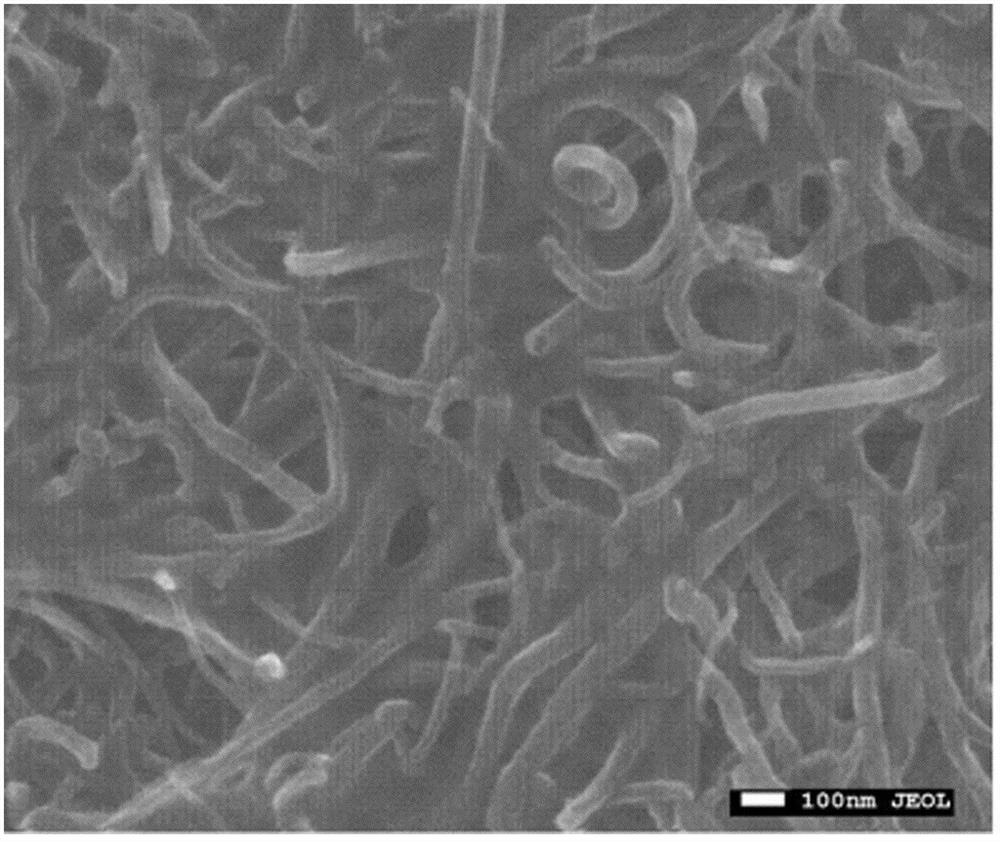

[0044] S2. At a temperature of 40-50°C, add nano-carbon materials into the first mixture of S1. The nano-carbon materials are self-made aligned multi-walled carbon nanotubes with a diameter of 10-50 nm and a length of 10-200 μm, weighing 0.5 -2g, after pre-ultrasonic treatment, add it into the four-necked flask containing th...

Embodiment 3

[0049] S1. Put 5-10ml of acetone in a four-necked flask with a volume of 500ml, connected with mechanical stirring, condensing reflux, thermometer, nitrogen protection and a liquid filling port, and successively add 100g-110g of polyester di, 0.015-0.08g of fatty alcohol Emulsifier compounded with polyoxyethylene ether and 0.005-0.02g sodium dodecylbenzenesulfonate, flame retardant compounded with 3-5g aluminum hydroxide, 3-5g chlorinated paraffin and 1-3g trimethyl phosphate Dissolved in a four-neck flask, mechanically stirred in a fume hood at a speed of 100-500r / min, fed with nitrogen protection, condensed and refluxed at a temperature of 30-40°C to fully dissolve the components to obtain the first mixture;

[0050] S2. At a temperature of 40-50°C, add carbon nanomaterials to the first mixture of S1. The carbon nanomaterials are multi-walled carbon nanotubes with a diameter of 10-50 nm and a length of 10-50 μm, weighing 0.5- 1.5g, ultrasonically disperse in 50-100ml of eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com