Preparation method of super-hydrophobic surface with directional transport function

A super-hydrophobic surface and functional technology, which is applied in the process of producing decorative surface effects, manufacturing microstructure devices, decorative arts, etc. Accurate location of vapor deposition, improve superhydrophobicity, and achieve the effect of directional transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

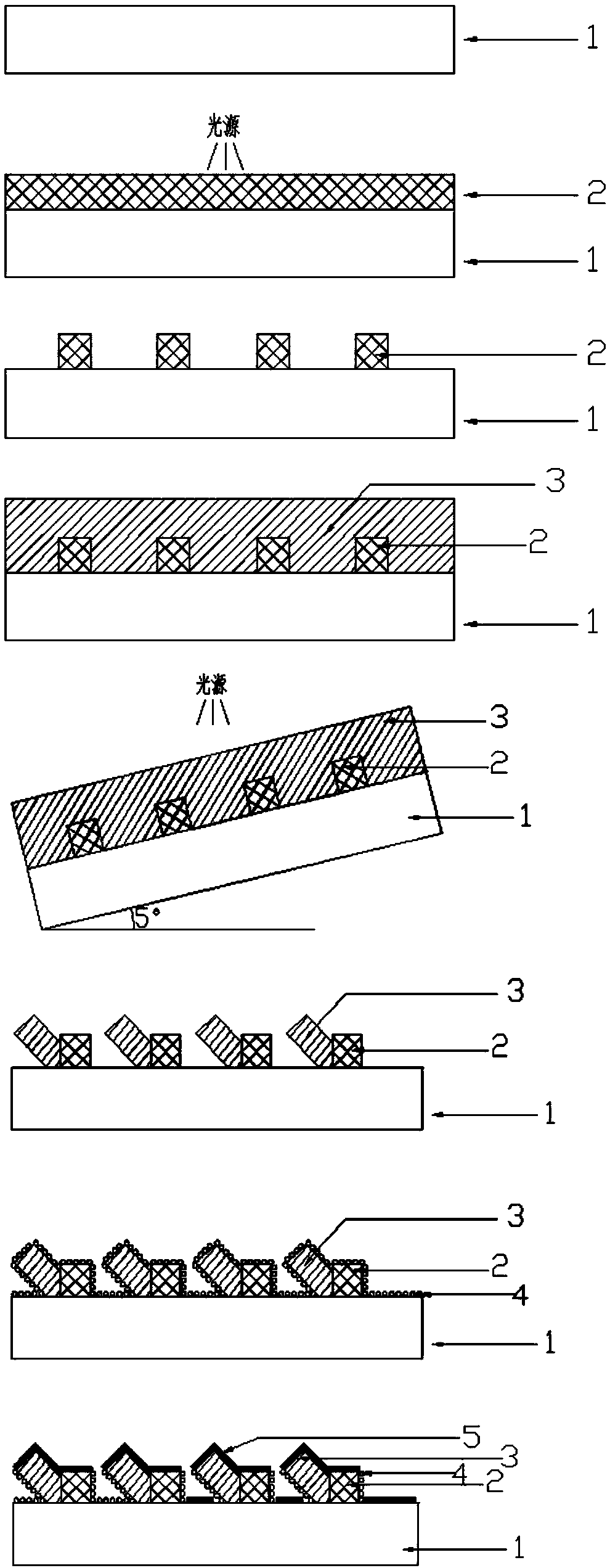

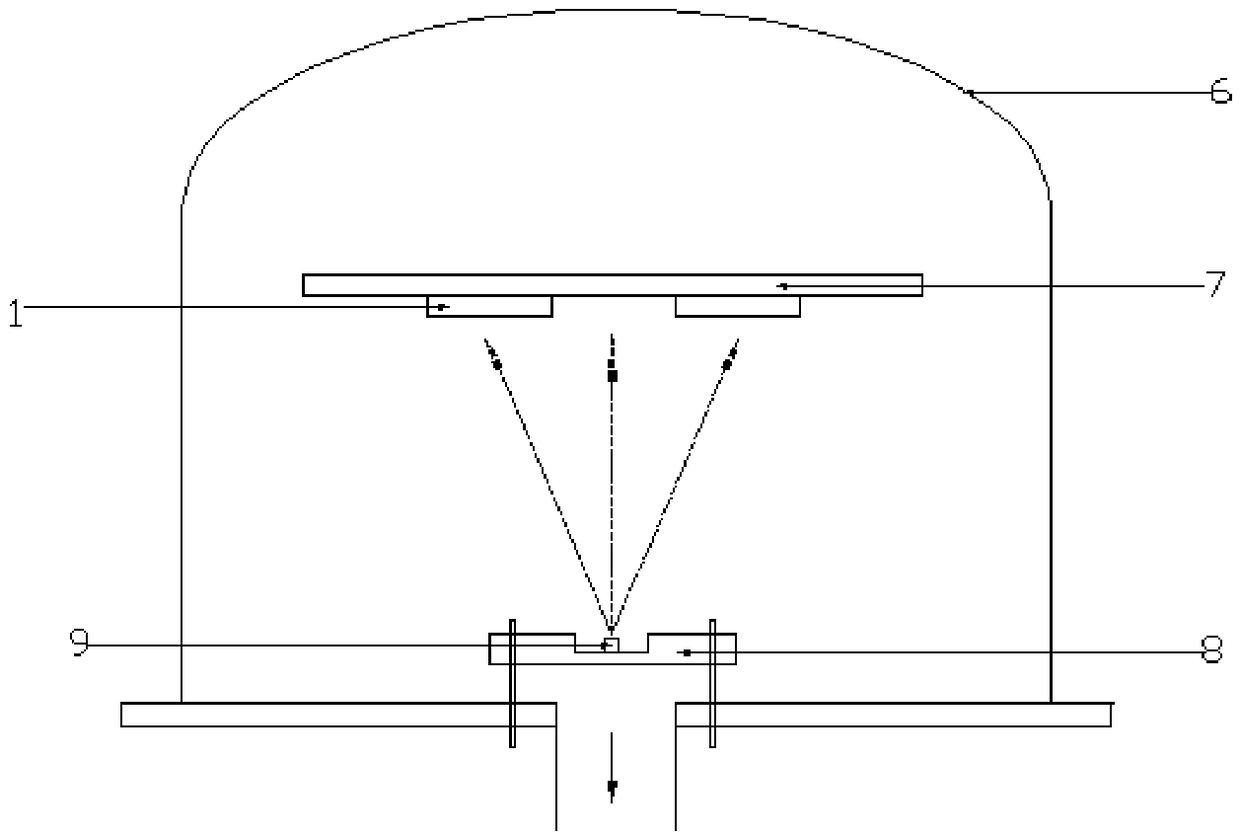

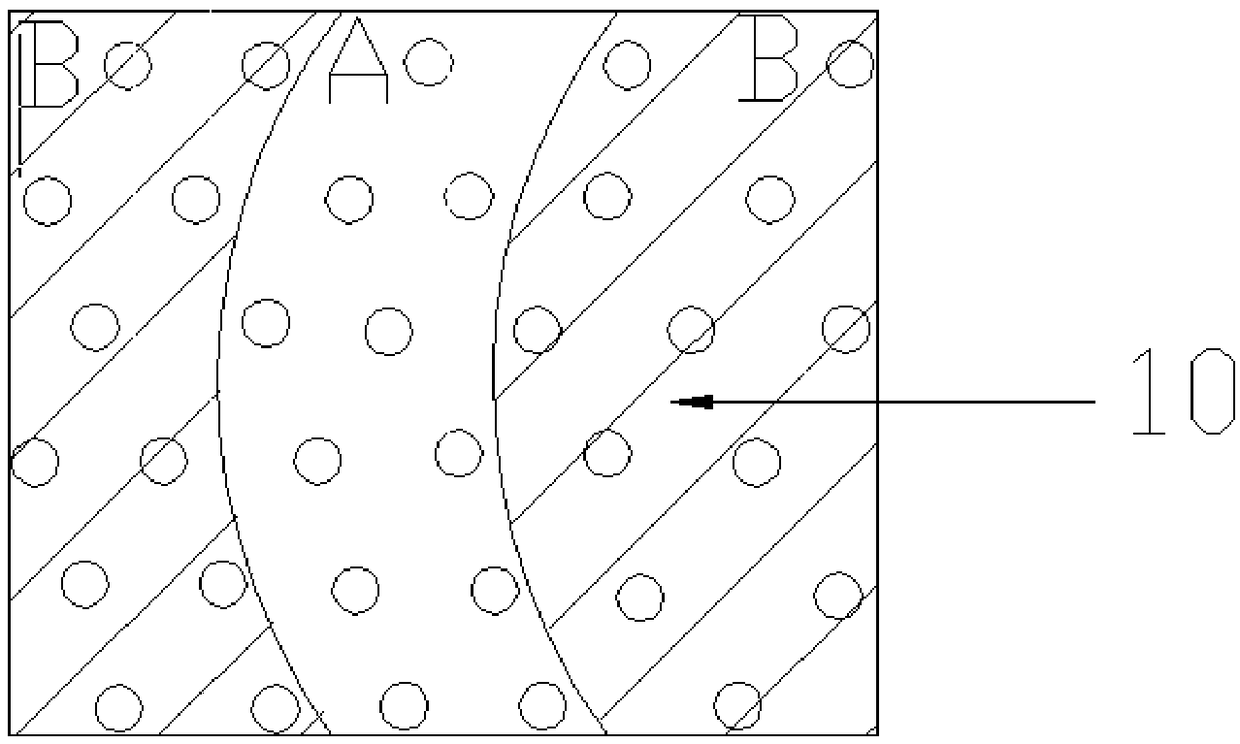

[0059] In conjunction with the accompanying drawings, a method for preparing a superhydrophobic surface with directional transport function, comprising the following steps:

[0060] The first step is to spin-coat UV photoresist (positive resist) for the first UV photolithography

[0061] (1) According to the needs, pre-design the pattern to be photolithographic;

[0062] (2) Take a silicon substrate 1 with a size of 25mm×25mm, ultrasonically clean it with acetone, ethanol, and deionized water for 10 minutes, and dry it with nitrogen;

[0063] (3) Put the clean silicon substrate 1 on the homogenizer, use a micropipette to drop an appropriate amount of UV photoresist 2 (positive resist) on the silicon substrate 1, the model is AZ5214E, and set the pre-spin coating speed and time were 500rpm and 10s respectively, and the rotating speed and time of spin coating were 4000rpm and 30s respectively, and the glue was evenly distributed;

[0064] (4) Horizontally fix the silicon subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com