Manganese dioxide and sulfite system and preparation method and application thereof

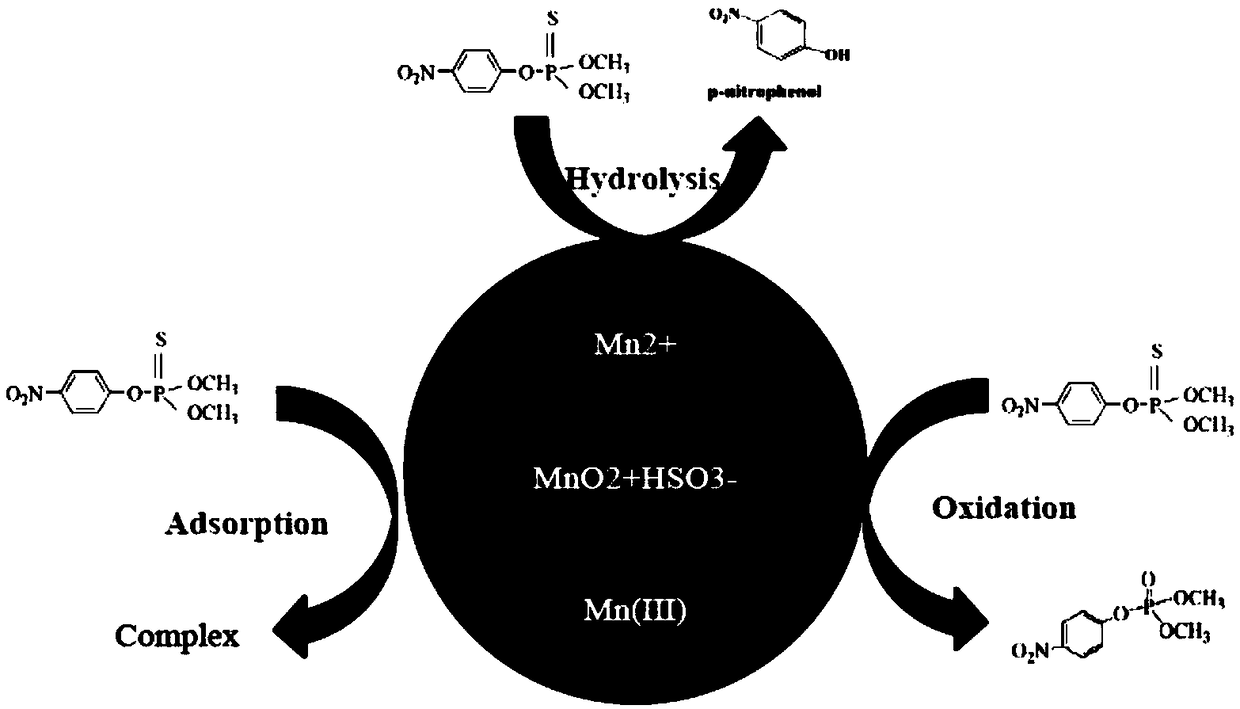

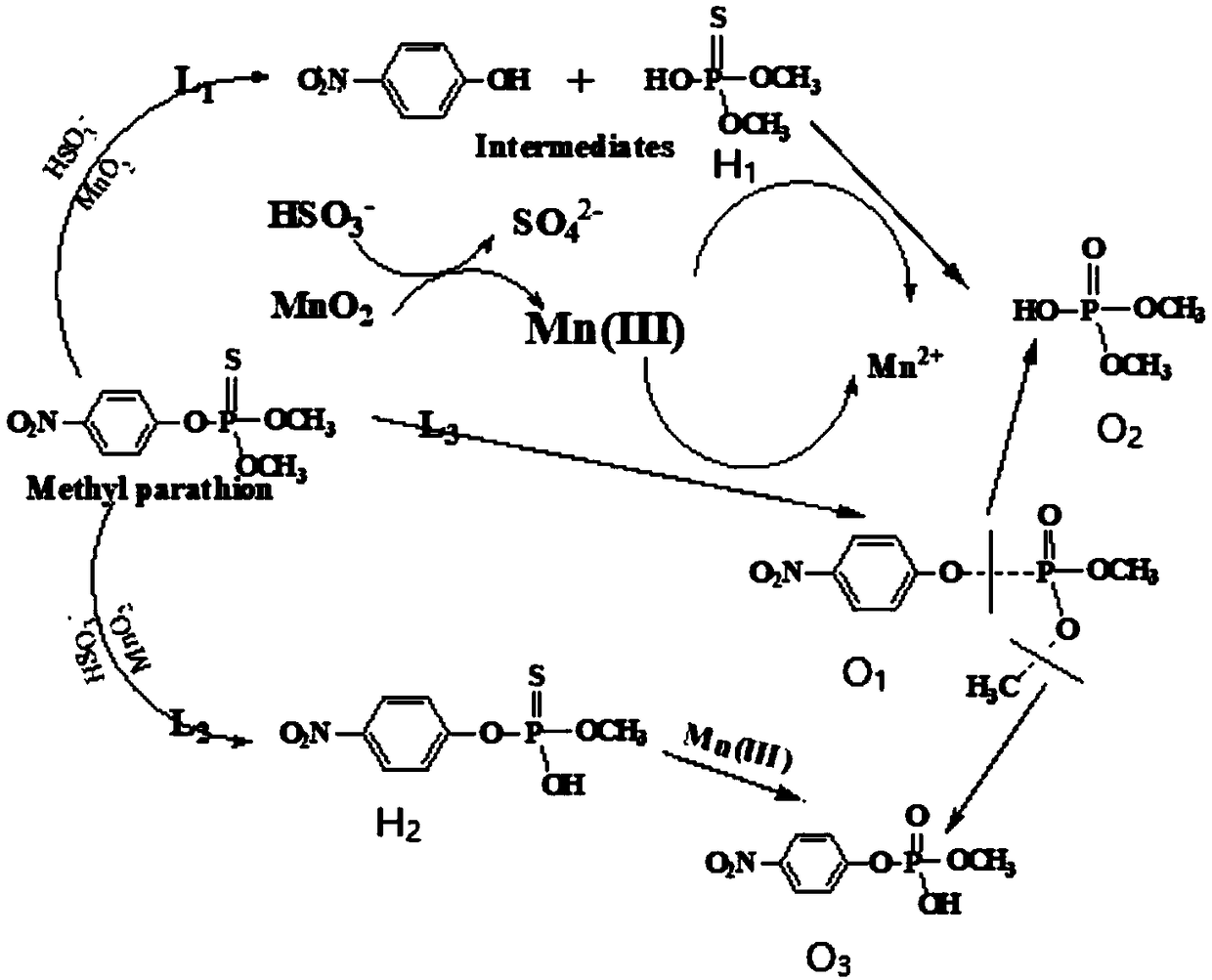

A technology of sulfite and manganese dioxide, which is applied in chemical instruments and methods, oxidized water/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc. Low affinity and other problems, achieve low cost, increase hydrolysis and oxidative degradation rate, and improve oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation process of nano manganese dioxide is:

[0037] Step S1.1, to manganese sulfate (MnSO 4 ·H 2 0) adding ultrapure water to the solid, heating in a water bath, and stirring until the manganese sulfate solid is completely dissolved to obtain an aqueous solution of manganese sulfate;

[0038] Step S1.2, adding potassium permanganate aqueous solution to the manganese sulfate aqueous solution, stirring while adding, standing still, then removing the supernatant, retaining the precipitate, and repeatedly washing the precipitate with ultrapure water until the supernatant is colorless, Obtain manganese dioxide mineral;

[0039] Step S1.3, using ultrapure water to repeatedly wash the manganese dioxide mineral until the conductivity of the filtrate obtained by filtering is lower than 0.2ms·cm -1 ;

[0040] Step S1.4, drying the manganese dioxide mineral, grinding and sieving to obtain nano manganese dioxide.

[0041] The embodiment of the present invention also...

Embodiment 1

[0058] Preparation of nano manganese dioxide: accurately weigh 81.12g manganese sulfate (MnSO 4 ·H 2 O) Transfer the solid to a 1000mL beaker, add ultrapure water to 300mL, then heat in a water bath to 90°C, and keep stirring until the manganese sulfate solid is completely dissolved to obtain a molar concentration of 1.6mol L -1 manganese sulfate aqueous solution; 60 ℃ potassium permanganate aqueous solution (volume is 400mL, molar concentration is 0.8mol L -1 ) was slowly added into the manganese sulfate aqueous solution at a temperature of 90°C with a separatory funnel, and stirred continuously with a glass rod while adding, until the reaction solution returned to 90°C, and kept at this temperature for about 30 minutes. In order to remove excess potassium permanganate, first pour off the supernatant that has been left to stand for stratification, then wash the precipitate with ultra-pure water at 60°C, repeatedly stir, let stand, and pour off the supernatant until the super...

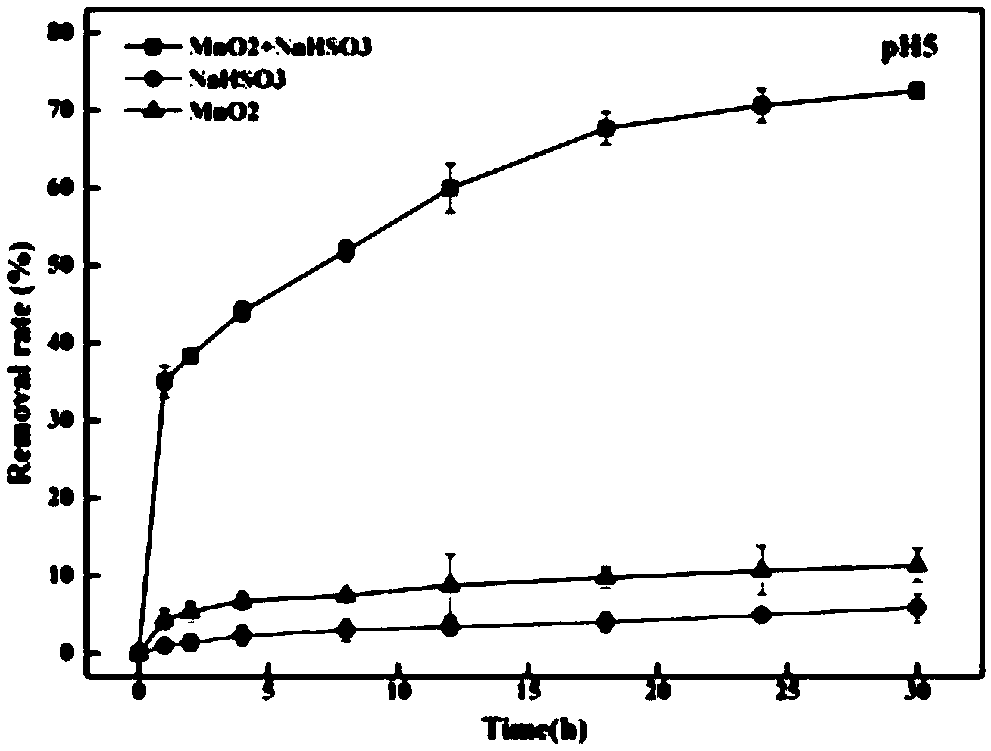

Embodiment 2

[0063] The difference between embodiment 2 and embodiment 1 is only: sodium bisulfite is not added in the methyl parathion solution; all the other are then substantially the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com