Pressure-resistant and anti-cracking wood-plastic composite with high strength

A wood-plastic composite material and high-strength technology, which is applied in the field of high-strength pressure-resistant and crack-resistant wood-plastic composite materials, can solve the problems of poor toughness and bending performance of wood-plastic composite materials, the impact of composite material performance stability, and composite compatibility effects To achieve the effect of improving high temperature resistance and thermal stability, improving flame retardancy and self-extinguishing performance, and uniform properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

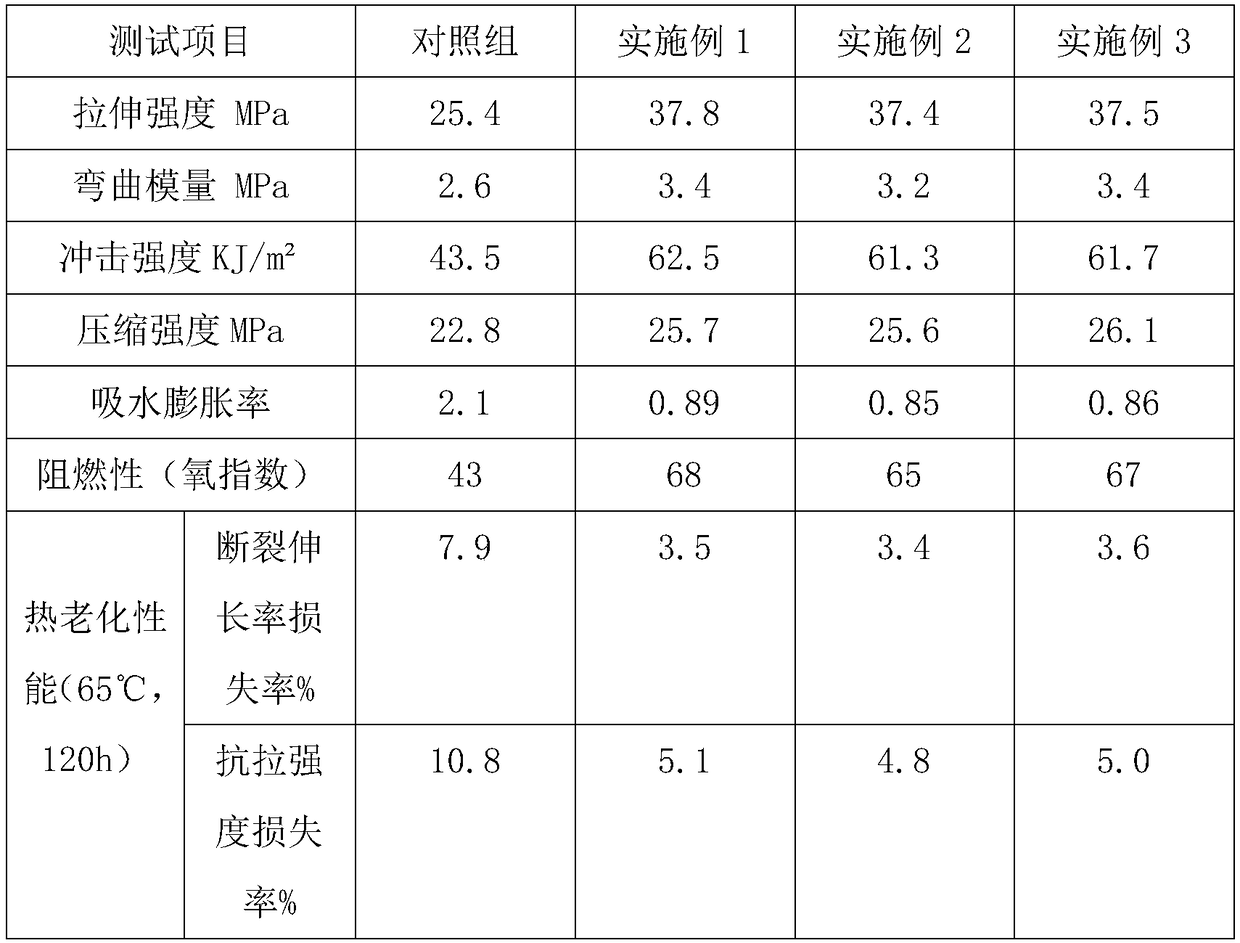

Embodiment 1

[0036] A high-strength pressure-resistant and crack-resistant wood-plastic composite material. According to the mass parts, the components of the wood-plastic composite material include: 60 parts of polypropylene resin, 6 parts of polyolefin thermoplastic elastomer, 8 parts of compatibilizer, wood powder 55 parts, 12 parts of modified asbestos fiber, 6 parts of magnesium hydroxide, 3 parts of lubricant, 1 part of silane coupling agent, 1.5 parts of dibutyl phthalate, 1.8 parts of dibasic lead phosphite, 1 part of anti-aging agent share.

[0037] Among them, the wood powder is made of fir wood powder with a water content of less than 3%, and the wood powder is impregnated with a flame retardant solution under high pressure before use. The flame retardant solution is composed of silica sol, ammonium polyphosphate, sodium octaborate tetrahydrate and carbonic acid. It is prepared by adding water to aluminum.

[0038] The compatibilizer is maleic anhydride grafted polypropylene; t...

Embodiment 2

[0043] A high-strength pressure-resistant and crack-resistant wood-plastic composite material. According to the mass parts, the components of the wood-plastic composite material include: 70 parts of polypropylene resin, 9 parts of polyolefin thermoplastic elastomer, 10 parts of compatibilizer, wood powder 75 parts, 17 parts of modified asbestos fiber, 9 parts of magnesium hydroxide, 5 parts of lubricant, 3 parts of silane coupling agent, 2.5 parts of dibutyl phthalate, 2.3 parts of dibasic lead phosphite, 2 parts of anti-aging agent share.

[0044] Among them, the wood powder is made of pine wood powder with a water content of less than 3%, and the wood powder is impregnated with a flame retardant solution under high pressure before use. The flame retardant solution is composed of silica sol, ammonium polyphosphate, sodium octaborate tetrahydrate and carbonic acid It is prepared by adding water to aluminum.

[0045] The compatibilizer is maleic anhydride grafted polypropylene...

Embodiment 3

[0050] A high-strength pressure-resistant and crack-resistant wood-plastic composite material. According to the mass parts, the components of the wood-plastic composite material include: 66 parts of polypropylene resin, 7.5 parts of polyolefin thermoplastic elastomer, 9 parts of compatibilizer, wood powder 63 parts, 15 parts of modified asbestos fiber, 7.5 parts of magnesium hydroxide, 4 parts of lubricant, 2.2 parts of silane coupling agent, 2.1 parts of dibutyl phthalate, 2 parts of dibasic lead phosphite, 1.8 parts of anti-aging agent .

[0051] Among them, the wood powder is made of fir wood powder with a water content of less than 3%, and the wood powder is impregnated with a flame retardant solution under high pressure before use. The flame retardant solution is composed of silica sol, ammonium polyphosphate, sodium octaborate tetrahydrate and carbonic acid. It is prepared by adding water to aluminum.

[0052] The compatibilizer is maleic anhydride grafted polypropylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com