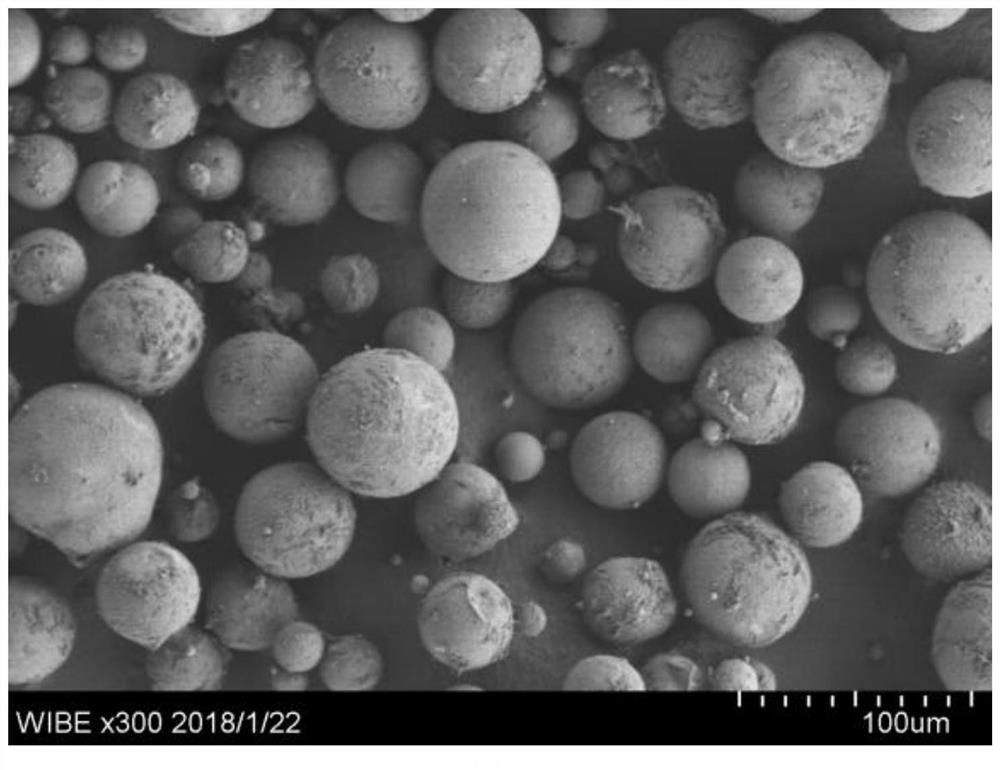

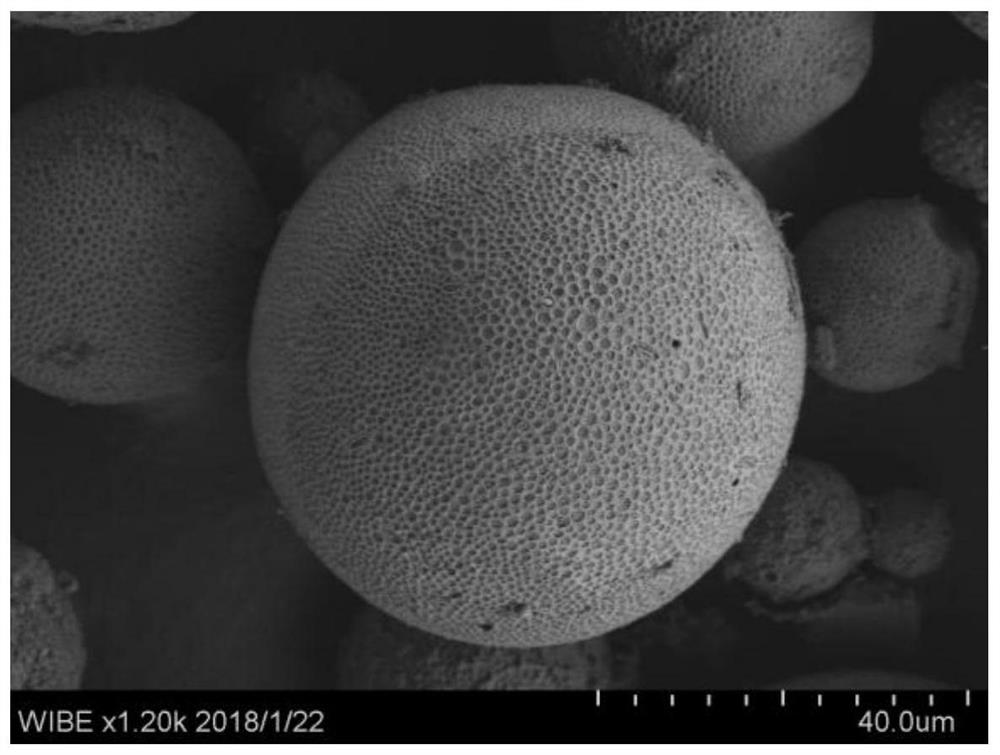

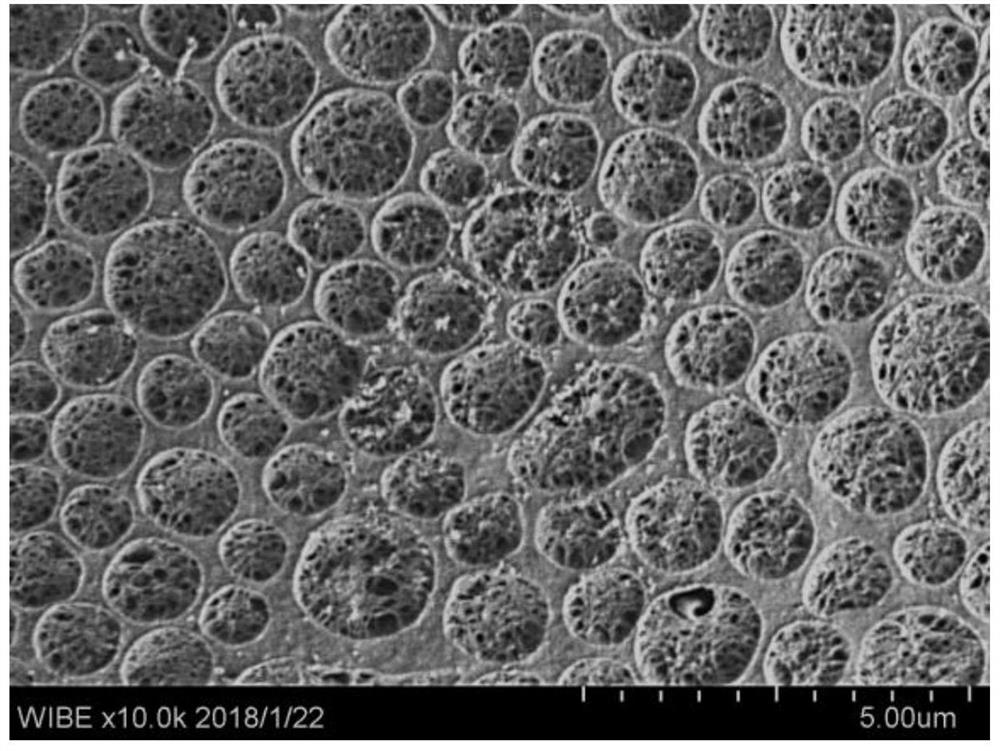

Application of pit-hole composite micro-nano structured polysaccharide microspheres in the preparation of hemostatic dressings

A technology of micro-nano structure and hemostatic dressing, which is applied in application, surgical adhesives, surgery, etc., can solve the problems of single structure, large particle size distribution, and difficult to control microscopic morphology, and achieve uniform particle size distribution and high porosity , the effect of good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of pit-hole composite micro-nano structure polysaccharide microspheres comprises the following steps:

[0044] (1) The mass ratio is 1:2:2, the degree of substitution: ≥80%, carboxymethyl chitosan with a viscosity of 10mPa.s, a weight-average molecular weight of 100,000 sodium hyaluronate and a viscosity of 100mPa.s Sodium alginate is dissolved in ultrapure water to make a polysaccharide aqueous solution with a mass concentration of 2%;

[0045] (2) Add the emulsifier obtained by mixing Span 85 and Tween-80 with a mass ratio of 1:1 into liquid paraffin so that the mass fraction of the emulsifier is 0.4%, stir and dissolve at 40°C to obtain emulsifier-containing Oil phase; add the polysaccharide aqueous solution dropwise to the oil phase containing the emulsifier at room temperature, stir and emulsify at 500rpm, and the stirring time is 4h to obtain a uniform emulsion; the mass ratio of the oil phase containing the emulsifier to the polysaccharide ...

Embodiment 2

[0052] The preparation method of pit-hole composite micro-nano structure polysaccharide microspheres comprises the following steps:

[0053] (1) Dissolving carboxymethyl cellulose with a mass ratio of 1:1:1 with a viscosity of 4500mPa.s, carboxymethyl dextran with a weight average molecular weight of 100,000, and sodium hyaluronate with a weight average molecular weight of 500,000 in ultrapure In water, it is made into a polysaccharide aqueous solution with a mass concentration of 10%;

[0054] (2) Add the emulsifier Span 80 into the soybean oil so that the mass fraction of the emulsifier is 5%, stir and dissolve at 80°C to obtain an oil phase containing the emulsifier; then add the polysaccharide aqueous solution dropwise at room temperature Into the oil phase containing emulsifier, stir and emulsify at 800rpm, and stir for 1h to obtain a uniform emulsion; the mass ratio of oil phase containing emulsifier to polysaccharide aqueous solution is 3:1;

[0055] (3) ZnCl 2 Dissol...

Embodiment 3

[0061] The preparation method of pit-hole composite micro-nano structure polysaccharide microspheres comprises the following steps:

[0062] (1) Carboxymethyl dextran with a weight average molecular weight of 80,000, a weight average molecular weight of 400,000 sodium hyaluronate, and a viscosity of 150mpa.s sodium alginate dissolved in ultrapure water with a mass ratio of 2:1:1, It is made into a polysaccharide aqueous solution with a mass concentration of 6%;

[0063] (2) The emulsifier obtained by mixing Span 60 and Triton X-100 with a mass ratio of 4:1 is added to liquid paraffin and normal hexane with a mass ratio of 5:1, so that the mass fraction of the emulsifier is 1%. ℃, stirring and dissolving to obtain an oil phase containing an emulsifier; then add the polysaccharide aqueous solution dropwise to the oil phase containing an emulsifier at room temperature, stir and emulsify at 600 rpm for 2 hours, and obtain a uniform emulsion; The mass ratio of oil phase and polysa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com