Method for preparing acetonitrile

A technology of acetonitrile and carrier, applied in the field of highly selective preparation of acetonitrile, which can solve the problems of environmental pollution and hazards, and achieve the effect of sufficient raw material sources and recyclable raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

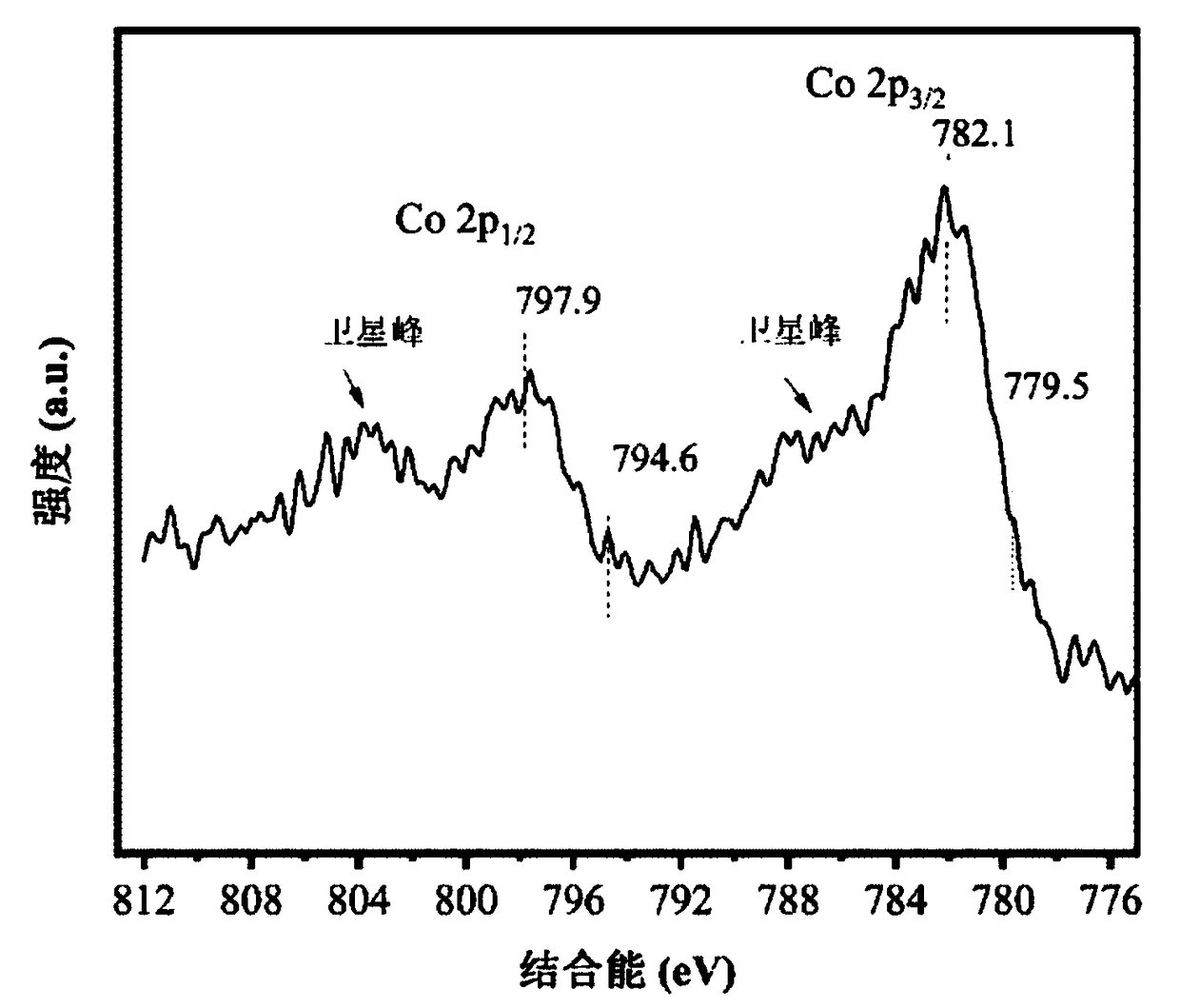

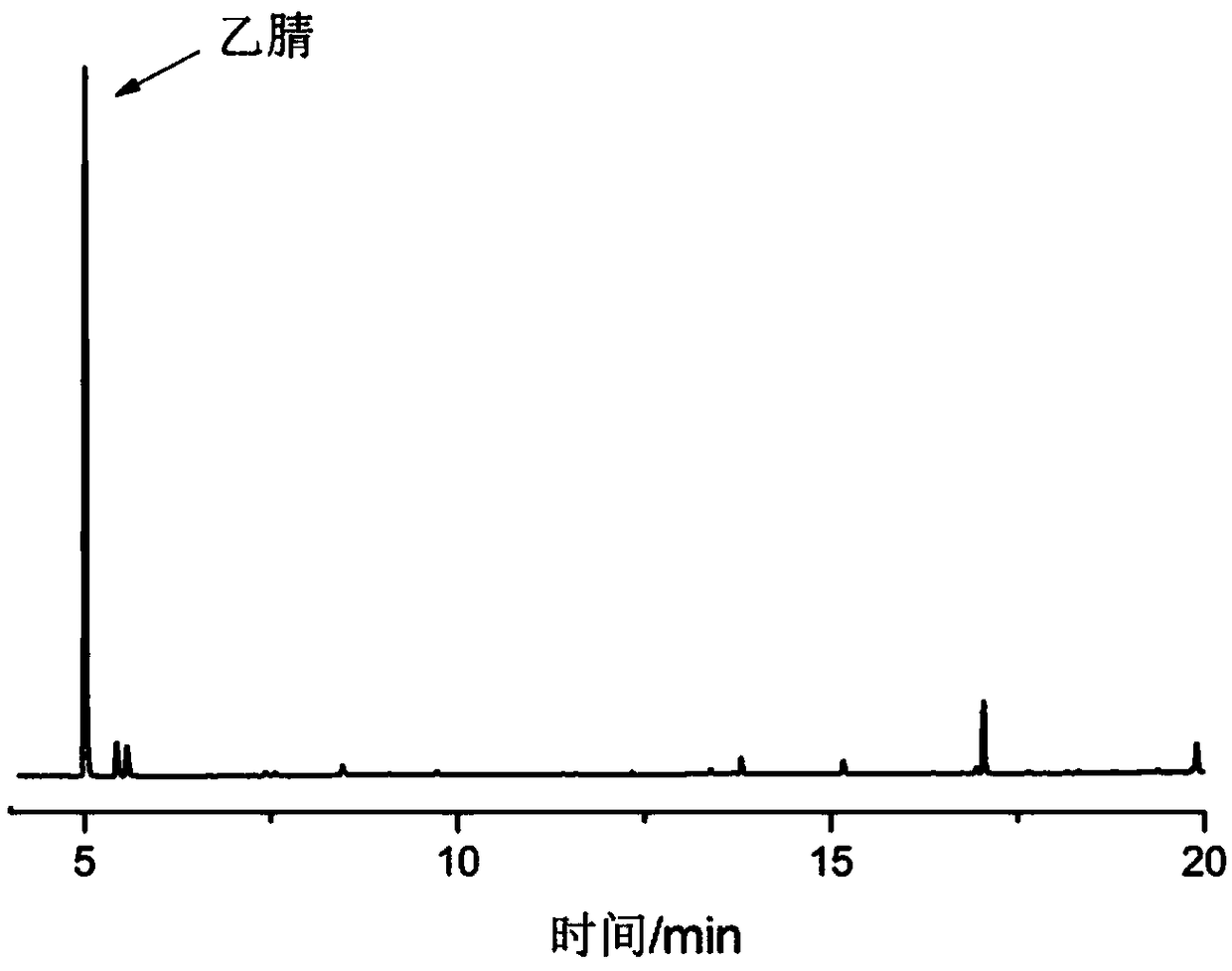

[0058] Example 1: Test the influence of different catalysts loaded on HZSM-5 molecular sieves with different types of active metal oxides on the selectivity and yield of acetonitrile

[0059] In this example, different metals (Fe, Cu, Zn, Ni, Co, Cr, Mg, Ca, Ga, and Zr) were supported on the HZSM-5 molecular sieve carrier by the aforementioned impregnation method, wherein based on the total mass of the catalyst, The content of active metal oxides (calculated by their corresponding metal elements) is 2.0wt%.

[0060] Reaction conditions: The raw material is waste organic plastic powder composed of 3.0g of polylactic acid, 1.0g of polybutylene succinate and 1.0g of polyethylene succinate after grinding; use various powders after grinding Catalyst (<140 mesh) and the loading amount of the catalyst is 1.0 g; the carrier gas is composed of 100% ammonia and the flow rate is 80 ml / min; the reaction temperature is 650° C.; the feed reaction time is 30 min.

[0061] The liquid organic...

Embodiment 2

[0065] Embodiment 2: Test the impact of different catalysts loaded on different carriers with Co metal oxides on the selectivity and yield of acetonitrile

[0066] In this example, the corresponding catalysts were obtained by loading active metal Co on different supports by impregnation method, wherein the content of active metal oxides (calculated as Co element) was 2.0 wt% based on the total mass of the catalyst.

[0067] Reaction conditions: The raw material is waste organic plastic powder composed of 3.0g of polylactic acid, 1.0g of polybutylene succinate and 1.0g of polyethylene succinate after grinding; use various powders after grinding Catalyst (<140 mesh) and the loading amount of the catalyst is 1.0 g; the carrier gas is composed of 100% ammonia and the flow rate is 80 ml / min; the reaction temperature is 650° C.; the feed reaction time is 30 min.

[0068] According to the same program of Example 1, the results of the acetonitrile selectivity (%), acetonitrile yield (...

Embodiment 3

[0072] Example 3: Test the catalytic effect of Ni / HZSM-5 catalyst on the preparation of acetonitrile from waste organic plastics composed of different components.

[0073] In this example, the Ni / HZSM-5 catalyst obtained in Example 1 was used, wherein the content of active metal oxide (calculated as Ni element) was 2.0 wt% based on the total mass of the catalyst.

[0074] Reaction conditions: the raw material is waste organic plastic powder (5.0 g) composed of polylactic acid, polybutylene succinate and polyethylene succinate respectively after grinding; use ground Ni / HZSM-5 Powdered catalyst (<140 mesh) and the loading amount of the catalyst is 1.0g; the carrier gas is composed of 100% ammonia and the flow rate is 80ml / min; the reaction temperature is 650°C; the feed reaction time is 30min.

[0075] According to the same program of Example 1, the results of the acetonitrile selectivity (%), acetonitrile yield (%), propionitrile yield (%) and liquid organic product yield (%) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com