Device and method for determining calcium content in cigarette paper

A technology of calcium content and cigarette paper, applied in the field of chemical detection, can solve the problems of long processing time, slow detection speed, cumbersome manual operation, etc., and achieve the effects of fast processing, simple operation and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Reagent configuration

[0051] 0.05mol / L nitric acid background solution

[0052] Pipette 3.45mL of concentrated nitric acid into a beaker filled with 300mL of distilled water, stir, and place to cool. Make up to 1000mL with distilled water. Add Brij35 (100 mL plus 2 drops).

[0053] pH11H 3 BO 3 -H 3 PO 4 -HAC buffer solution

[0054] Weigh 0.5g of boric acid into a 100mL beaker, add about 40mL of distilled water and stir to dissolve, add 0.54mL of concentrated phosphoric acid and 0.48mL of glacial acetic acid, stir to dissolve, and dilute to 100mL with distilled water. Then pour this solution into a 500mL beaker, and adjust the pH value to 11 with 0.5mol / L sodium hydroxide. Add Brij35 (100 mL plus 2 drops).

[0055] 1.0g / L developer

[0056] Weigh 0.1 g of DBC-ASA (DBC-arsine) and dissolve it in 100 mL of distilled water to obtain a DBC-arsine aqueous solution with a concentration of 1.0 g / L.

[0057] Calcium standard stock solution

[0058] Take an app...

Embodiment 2

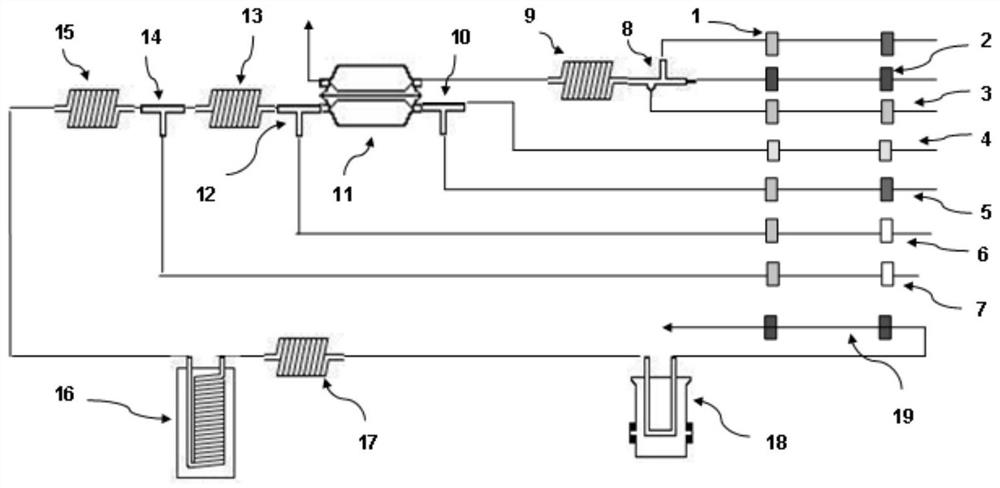

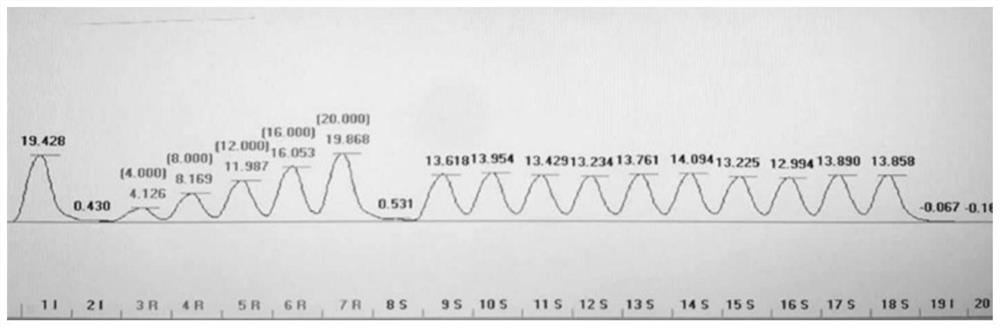

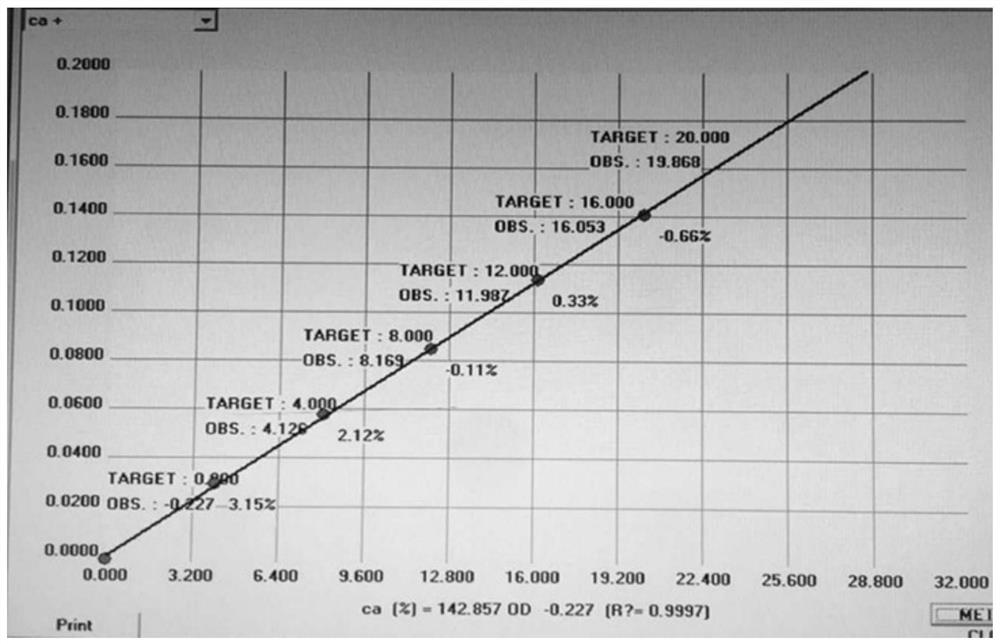

[0080] Measurement wavelength selection

[0081] according to figure 1 Test the calcium sample extract and background solution (0.05mol / L nitric acid) respectively, collect the color-developed sample extract a sample and background solution b sample from the waste liquid outlet of the flow analyzer, and measure the absorbance with a UV spectrophotometer scan, the result is as Figure 4 shown. As can be seen from the figure, Ca 2+ For the complex formed with DBC-Arsenazo, the maximum absorption wavelength is at 630nm, the maximum absorption wavelength of the reagent blank is at 540nm, and 630nm is selected as the optimum wavelength for measurement in the experiment.

Embodiment 3

[0083] Optimization of test conditions

[0084] 1. The effect of pH on absorbance

[0085] According to the experimental method, the influence of buffer solution pH9.0~13.0 on the absorbance was investigated, and the results showed that the absorbance was the largest and the fluctuation was small at pH10~11, and pH11 was selected for the experiment.

[0086] 2. Effect of chromogenic agent on absorbance

[0087] The amount of chromogenic agent was tested at 0.6-1.6g / L, and the results showed that the absorbance of DBC-arsine was the largest at 1-1.1g / L, and 1g / L was selected for the experiment.

[0088] 3. Complex composition ratio

[0089] Using the molar ratio method and the equimolar continuous change method, the composition ratio of the complex is n(Ca):n(DBC-ASA)=1:2.

[0090] 4. Interference effects of coexisting ions

[0091] The content of the main interfering elements Mg, Al, etc. that coexist in cigarette paper is very low. The test found that under the selected D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com