Environmentally-friendly mirror-surface tempered porcelain-imitation putty powder and preparation process thereof

A technology of putty powder and imitation porcelain, applied in the direction of filling slurry, etc., can solve the problem of shortage of decoration materials and other problems, achieve broad application value and market prospects, elegant style, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

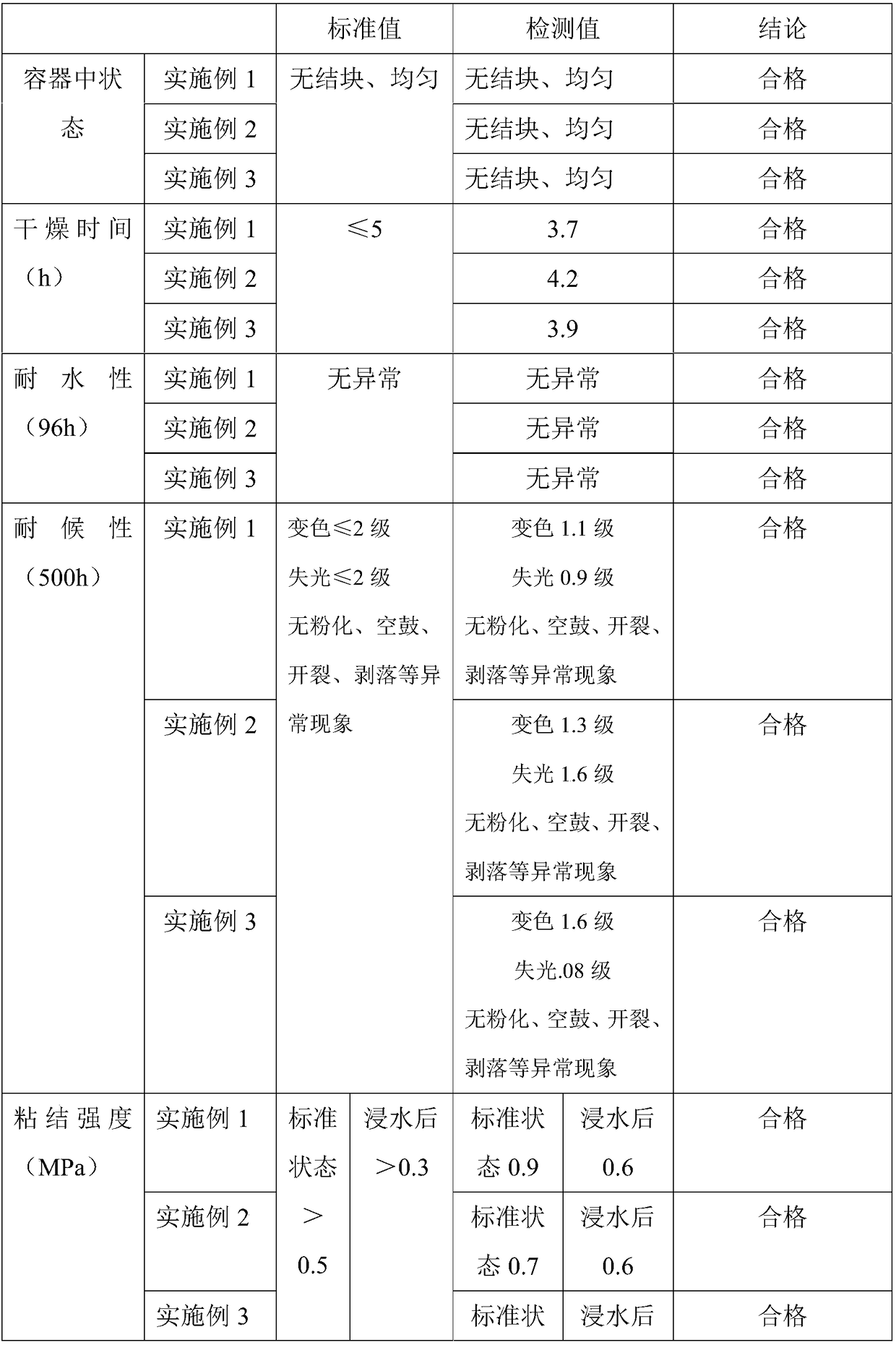

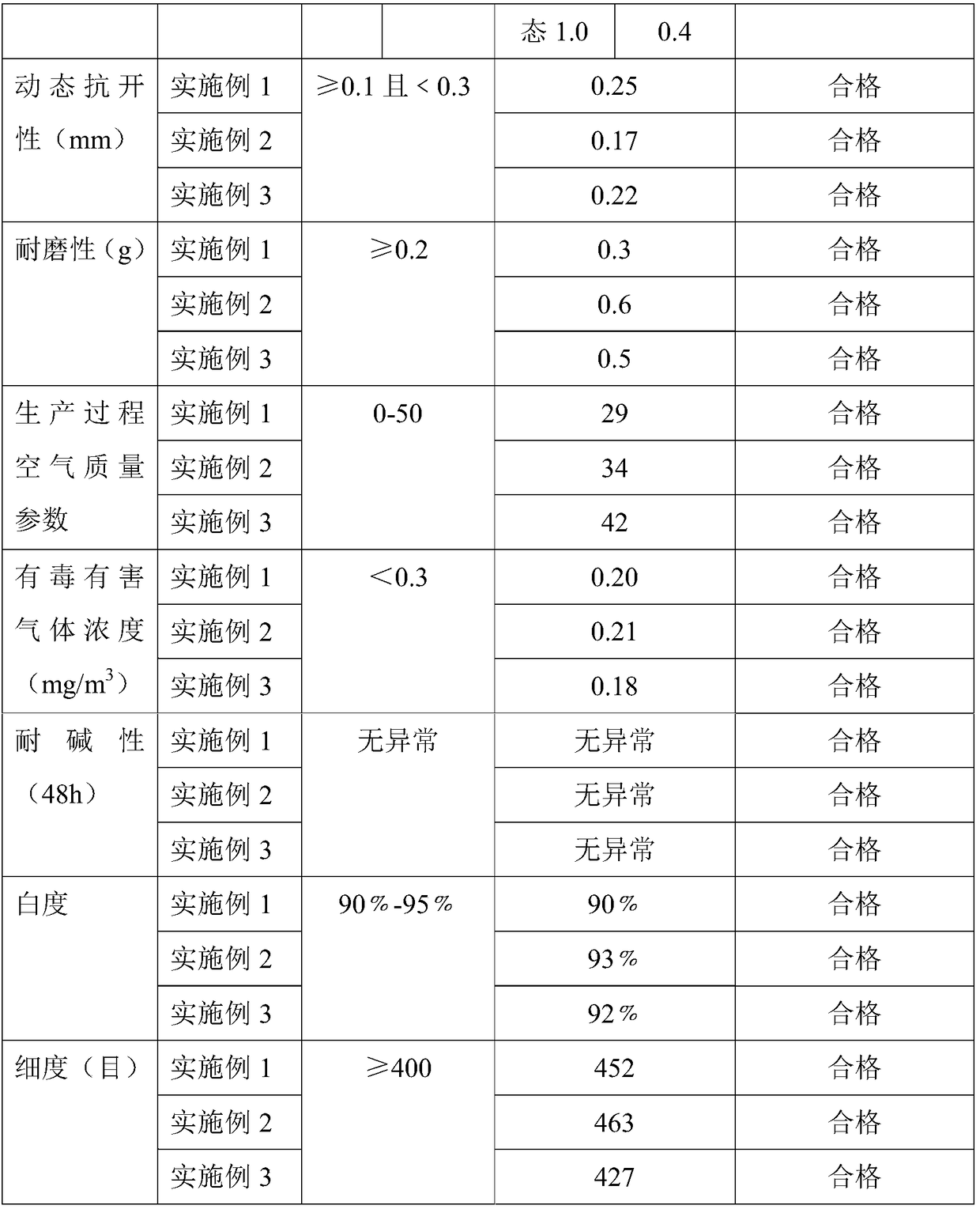

Examples

Embodiment 1

[0051] An environment-friendly mirror tempered porcelain-like putty powder, comprising the following raw materials in parts by weight: 120 parts of modified heavy calcium carbonate, 100 parts of light calcium carbonate, 60 parts of calcite powder, 60 parts of ash calcium powder, 60 parts of double fly powder, modified 40 parts of talcum powder, 10 parts of rubber powder, 20 parts of polyvinyl alcohol, 10 parts of bentonite, 20 parts of white cement, 5 parts of zinc white powder, 5 parts of sodium carboxymethyl cellulose, 2 parts of methyl cellulose, ethyl cellulose 2 parts of prime, 0.5 parts of polyacrylamide, 0.5 parts of liquid paraffin, 5 parts of nano-mirror flour, 5 parts of nano-reflective powder, 1.5 parts of fluorescent whitening agent, 1 part of dispersant, 0.2 parts of defoamer, 0.2 parts of emulsifier, 1 part of auxiliary agent.

[0052] The ash calcium powder is 20 parts of calcium hydroxide, 20 parts of calcium oxide and 20 parts of calcium carbonate.

[0053] T...

Embodiment 2

[0077] An environment-friendly mirror tempered porcelain-like putty powder, comprising the following raw materials in parts by weight: 130 parts of modified heavy calcium carbonate, 110 parts of light calcium carbonate, 70 parts of calcite powder, 65 parts of ash calcium powder, 68 parts of double fly powder, modified 57 parts of talcum powder, 14 parts of rubber powder, 26 parts of polyvinyl alcohol, 13 parts of bentonite, 26 parts of white cement, 10 parts of zinc white powder, 8 parts of sodium carboxymethyl cellulose, 3 parts of methyl cellulose, ethyl cellulose 3 parts of prime, 1 part of polyacrylamide, 0.7 part of liquid paraffin, 9 parts of nano-mirror flour, 7 parts of nano-reflective powder, 1.8 parts of fluorescent whitening agent, 2 parts of dispersant, 0.4 part of defoamer, 0.3 part of emulsifier, 1.5 parts of auxiliary agent.

[0078] The ash calcium powder is 30 parts of calcium hydroxide and 35 parts of calcium oxide.

[0079] The dispersant is 1 part of sodiu...

Embodiment 3

[0103] An environment-friendly mirror tempered porcelain-like putty powder, comprising the following raw materials in parts by weight: 150 parts of modified heavy calcium carbonate, 120 parts of light calcium carbonate, 80 parts of calcite powder, 70 parts of ash calcium powder, 70 parts of double fly powder, modified 60 parts of talcum powder, 20 parts of rubber powder, 30 parts of polyvinyl alcohol, 15 parts of bentonite, 30 parts of white cement, 15 parts of zinc white powder, 10 parts of sodium carboxymethyl cellulose, 5 parts of methyl cellulose, ethyl cellulose 4 parts of prime, 1.5 parts of polyacrylamide, 1 part of liquid paraffin, 10 parts of nano-mirror flour, 10 parts of nano-reflective powder, 2 parts of fluorescent whitening agent, 3 parts of dispersant, 0.5 part of defoamer, 0.5 part of emulsifier, 2 parts of auxiliary agent.

[0104] Described ash calcium powder is 70 parts in calcium hydroxide.

[0105] The dispersant is 3 parts of sodium polyacrylate.

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com