Method for preparing carbon nanotube

A technology of carbon nanotubes and quartz tubes, which is applied in the field of synthetic carbon nanotube materials, can solve the problems of modified montmorillonite, molecular sieves, high prices, restrictions on the development of carbon nanomaterials, and cumbersome preparation conditions, and achieves low price and low cost , source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Co‐Mo / MgO catalysts were prepared by combustion method. Grind cobalt nitrate, ammonium molybdate, and magnesium nitrate with a high-speed pulverizer, grind them thoroughly in a mortar, mix them in a molar ratio of 1:0.5:1, dissolve them with an appropriate amount of polyethylene glycol 200, stir them fully, and let them stand for 24 hours Then put it into a muffle furnace at 650°C for calcination for 1 hour, collect the product, cool it to room temperature, and grind it into a powder with a particle size of about 1 μm with a mortar to obtain a supported bimetallic Co-Mo / MgO catalyst.

[0022] According to the weight ratio, 86% polyethylene, 7% Co-Mo-Mg catalyst and 7% carbon black were uniformly mixed for 10 min in a torque rheometer at a temperature of 150 ° C and a rotation speed of 50 rpm to obtain a polyethylene mixture.

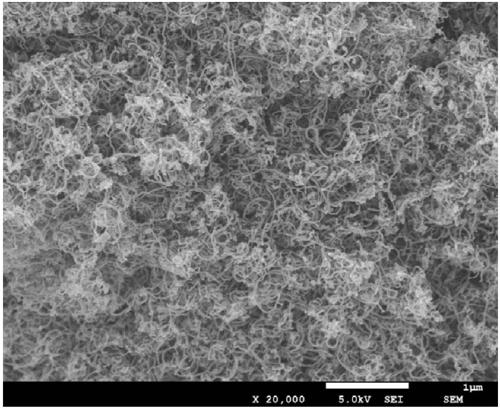

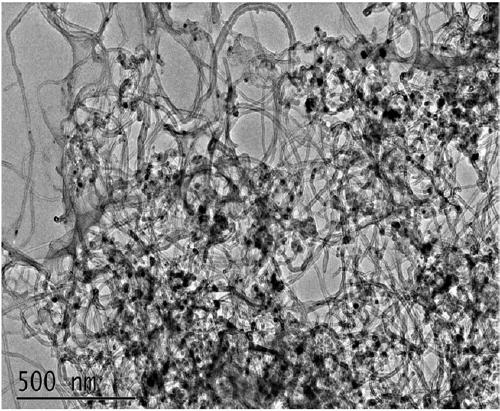

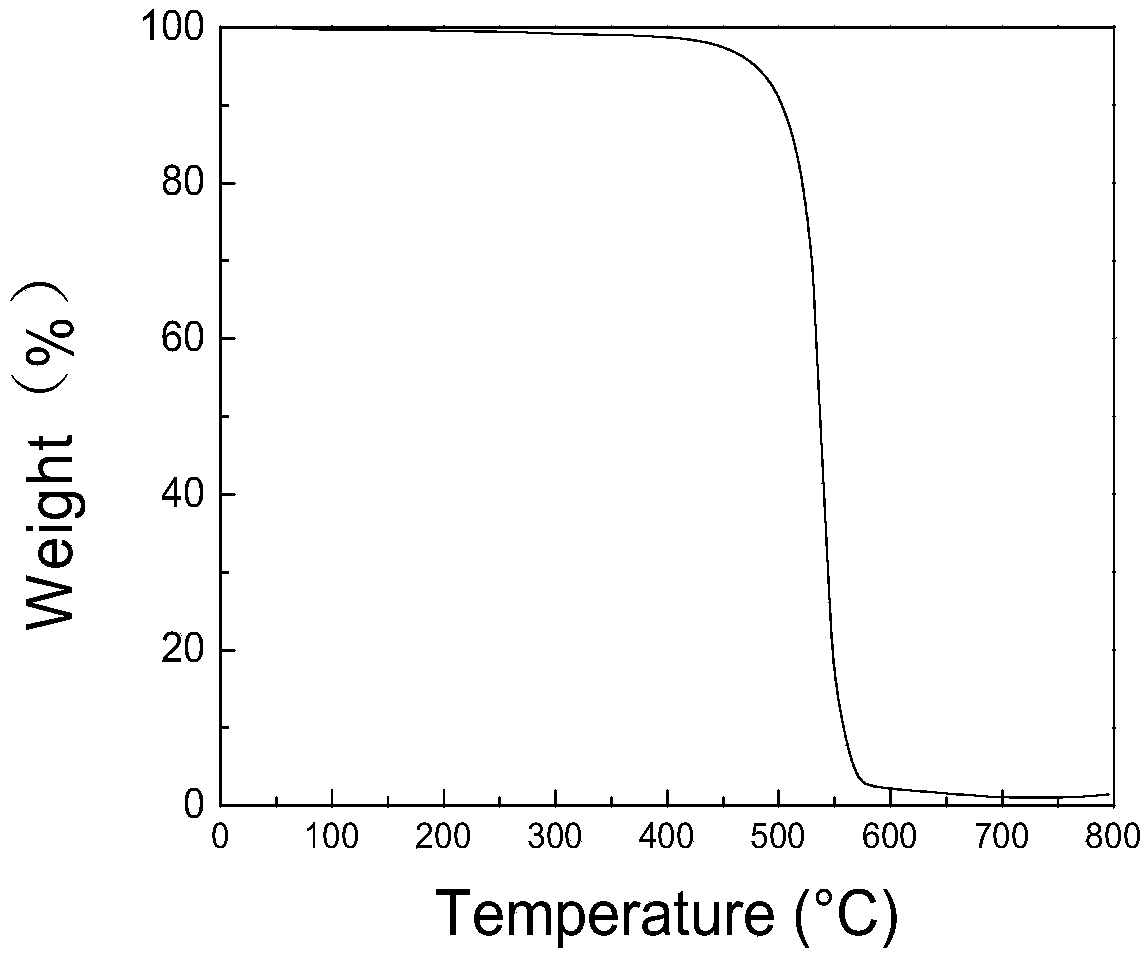

[0023] Take 5 g of the above-mentioned polymer and put it into a quartz tube, replace the air in the tube with nitrogen gas with a flow rate of 5...

Embodiment 2

[0026] Co‐Mo / MgO catalysts were prepared by combustion method. Grind cobalt nitrate, ammonium molybdate, and magnesium nitrate with a high-speed pulverizer, grind them thoroughly in a mortar, mix them in a molar ratio of 2:0.5:1, dissolve them with an appropriate amount of polyethylene glycol 200, stir them fully, and let them stand for 24 hours Then put it into a muffle furnace at 650°C for calcination for 1 hour, collect the product, cool it to room temperature, and grind it into a powder with a particle size of about 1 μm with a mortar to obtain a supported bimetallic Co-Mo / MgO catalyst.

[0027] According to the weight ratio, 86% polyethylene, 7% Co-Mo-Mg catalyst and 7% carbon black were uniformly mixed for 10 min in a torque rheometer at a temperature of 150 ° C and a rotation speed of 50 rpm to obtain a polyethylene mixture.

[0028] 5 g of the above blend was taken, prepared and purified by the method of Example 1, and 3 g of carbon nanotubes were obtained.

Embodiment 3

[0030] Co‐Mo / MgO catalysts were prepared by combustion method. Grind cobalt nitrate, ammonium molybdate, and magnesium nitrate with a high-speed pulverizer, grind them thoroughly in a mortar, mix them in a molar ratio of 3:0.5:1, dissolve them with an appropriate amount of polyethylene glycol 200, stir them fully, and let them stand for 24 hours Then put it into a muffle furnace at 650°C for calcination for 1 hour, collect the product, cool it to room temperature, and grind it into a powder with a particle size of about 1 μm with a mortar to obtain a supported bimetallic Co-Mo / MgO catalyst.

[0031] According to the weight ratio, 86% polyethylene, 7% Co-Mo-Mg catalyst and 7% carbon black were uniformly mixed for 10 min in a torque rheometer at a temperature of 150 ° C and a rotation speed of 50 rpm to obtain a polyethylene mixture.

[0032] 5 g of the above blend was taken, prepared and purified by the method of Example 1, and 2.97 g of carbon nanotubes were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com