Method for extracting undaria pinnatifida sulfated polysaccharide and application thereof in regulating intestinal flora

A technology for regulating intestinal flora and sulfated polysaccharides, which is applied in the field of food processing, can solve problems such as endangering personal safety and environmental pollution, and achieve the effects of improving purity, reducing volume, and facilitating dialysis and freeze-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

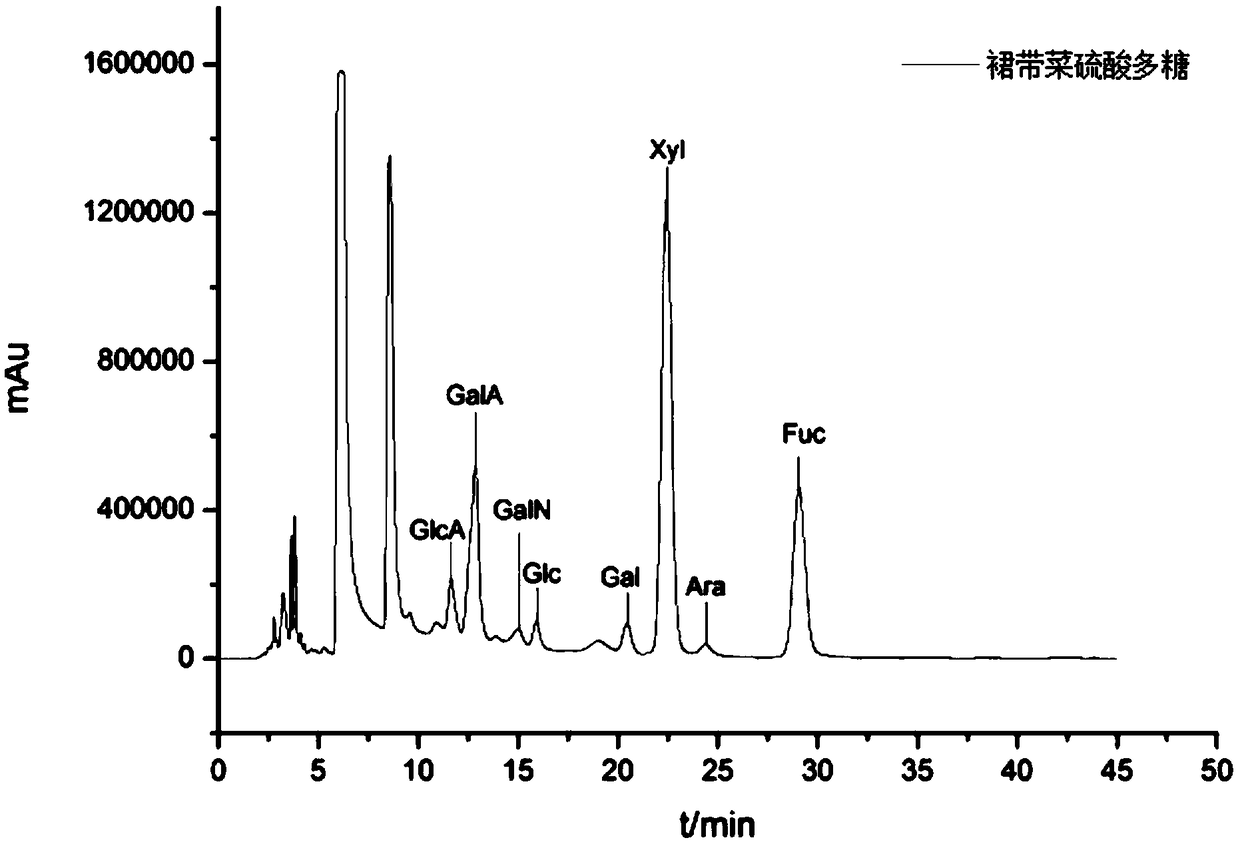

[0033] Embodiment 1: Preparation of Undaria pinnatae sulfate polysaccharide

[0034] S1, pulverize Undaria pinnatae (water content 3%~4%) into powder and pass through a 100-mesh sieve to obtain Undaria pinnatifida powder; weigh 70g of Undaria pinnatifida powder, add 1.75 L water, adjust temperature to 50 ℃ and utilize citric acid (1mol / l)-disodium hydrogen phosphate (2mol / l) buffer to adjust pH value to 4.8, add 14000U cellulase (the enzyme activity of described cellulase ≥ Stir at a constant speed of 50 U / mg) at 40 rpm / min for 15 min; then adjust the temperature to 45°C and pH to 4, add 7000 U of pectinase (the enzyme activity of the pectinase is ≥100 U / mg) and stir at a constant speed of 40 rpm / min for 1.5 h; Finally, adjust the temperature to 50°C and the pH value to 5.5, add 140000U papain (the enzyme activity of the papain is ≥2000U / mg) and stir at a constant speed of 40rpm / min for 1.5h, and wait for the mixture;

[0035] S2. Heat the mixed solution obtained in step S1 t...

Embodiment 2

[0043] Embodiment 2: Preparation of Undaria pinnatae sulfate polysaccharide

[0044] S1, pulverizing Undaria pinnatifida (water content 3%~4%) into powder and passing through a 100-mesh sieve to obtain Undaria pinnatifida powder;

[0045] Weigh 2000g of wakame powder, according to the ratio of material to liquid 1:30 (m / v), add 60L of water, adjust the temperature to 60°C and use citric acid (1mol / l)-disodium hydrogen phosphate (2mol / l) buffer Adjust the pH value to 5.2, add 440000U cellulase (enzyme activity ≥ 50U / mg) and stir at a constant speed of 60rpm / min for 25min; then adjust the temperature to 55°C and pH value to 4.4, add 280000U pectinase (enzyme activity ≥ 100U / mg ) at 60rpm / min for 2.5h at a constant speed; finally adjust the temperature to 60°C and the pH value to 6.5, add 5600000U papain (enzyme activity ≥ 2000U / mg) and stir at 60rpm / min for 2.5h at a constant speed to obtain a mixture;

[0046] S2. Heat the mixed solution obtained in step S1 to 95° C. for 10 minu...

Embodiment 3

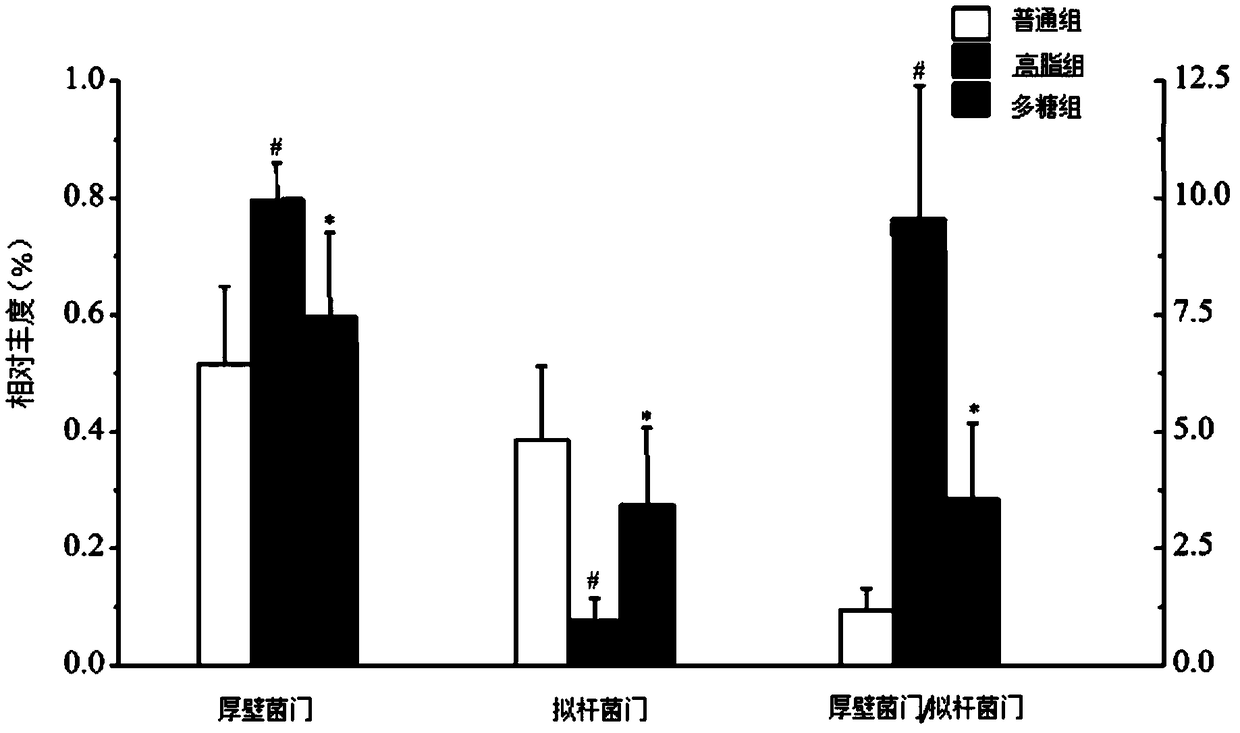

[0053] Example 3: Modulation of intestinal flora using wakame sulfated polysaccharides

[0054] (1) 36 BALB / c mice of the same batch (purchased from Dalian Medical University) were selected and divided into 3 groups, namely the normal group, the high-fat group and the polysaccharide group; the mice were given normal saline based on their body weight , undaria sulfate polysaccharide, normal group and high-fat group mice every day each gavage 500mg / Kg of normal saline, polysaccharide group mice every day each gavage wakame sulfate polysaccharide of 500mg / Kg, in the above three groups of mice The normal group was fed with normal feed, and the high-fat group and polysaccharide group were both fed with high-fat feed. After seven weeks, they were killed, and the contents of the colon were taken to extract DNA, and the microbial composition was analyzed by high-throughput sequencing; wherein, the wakame sulfate The polysaccharide was prepared by the embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com