Preparation method of super-crosslinked porous polyion liquid material and application

A polyionic liquid and hypercrosslinking technology, which is applied in the field of preparation of hypercrosslinked porous polyionic liquid materials, can solve problems such as difficulty in process control, and achieve the effects of wide application, high yield and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of preparation method of hypercrosslinked porous polyionic liquid material provided by the invention, its specific operation steps are as follows:

[0020] Step 1, the preparation of rigid cyanide ionic liquid monomer;

[0021] It is said that vinylimidazole and chloroacetonitrile are mixed according to the ratio of the mass of substances at 1:1, a polymerization inhibitor is added, and the amount of the polymerization inhibitor is 1% of the total mass, and tetrahydrofuran is added to form a 40% solution. After stirring for 48 hours, the corresponding ionic liquid was obtained, washed with ethyl acetate and ether three times in sequence, and then vacuum-dried at 60°C to obtain a rigid cyanide ionic liquid monomer, which was dissolved in a certain acetone solvent Finally, make a solution with a mass ratio concentration of 30%, add it to a solution containing potassium hexafluorophosphate for exchange, the molar amount of salt is 1.5 times that of the monomer, heat...

Embodiment 2-7

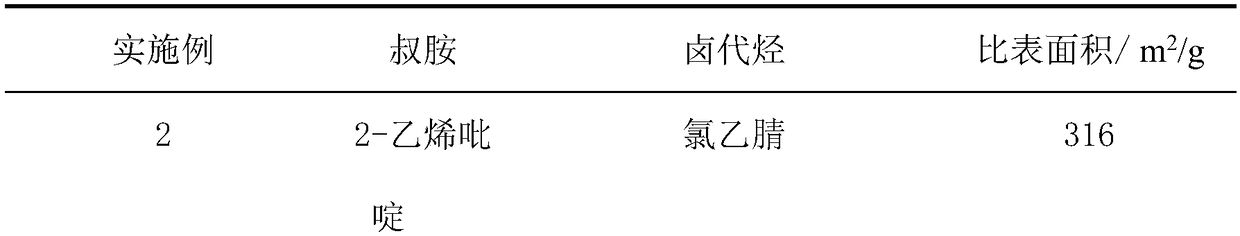

[0025] Except for the following differences, all the other are the same as in Example 1, using the tertiary amine compounds and halogenated hydrocarbons shown in Table 1 respectively.

[0026] Table 1

[0027]

[0028]

Embodiment 8-12

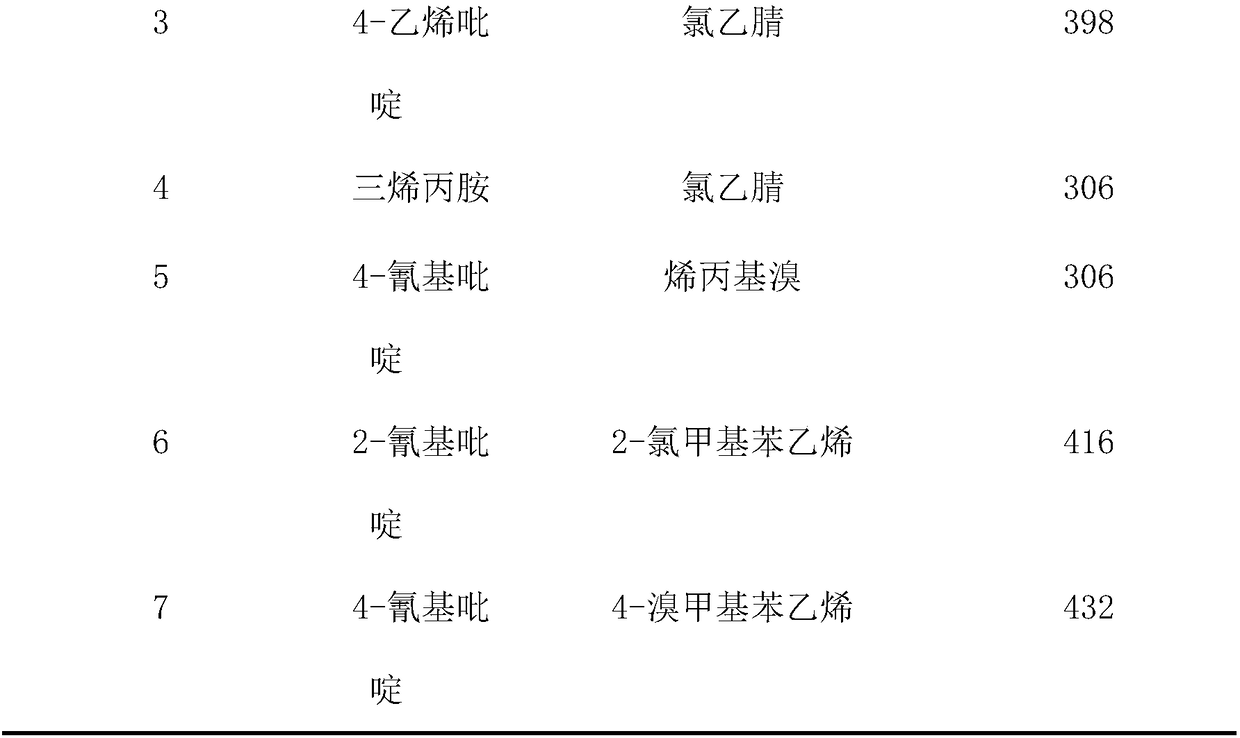

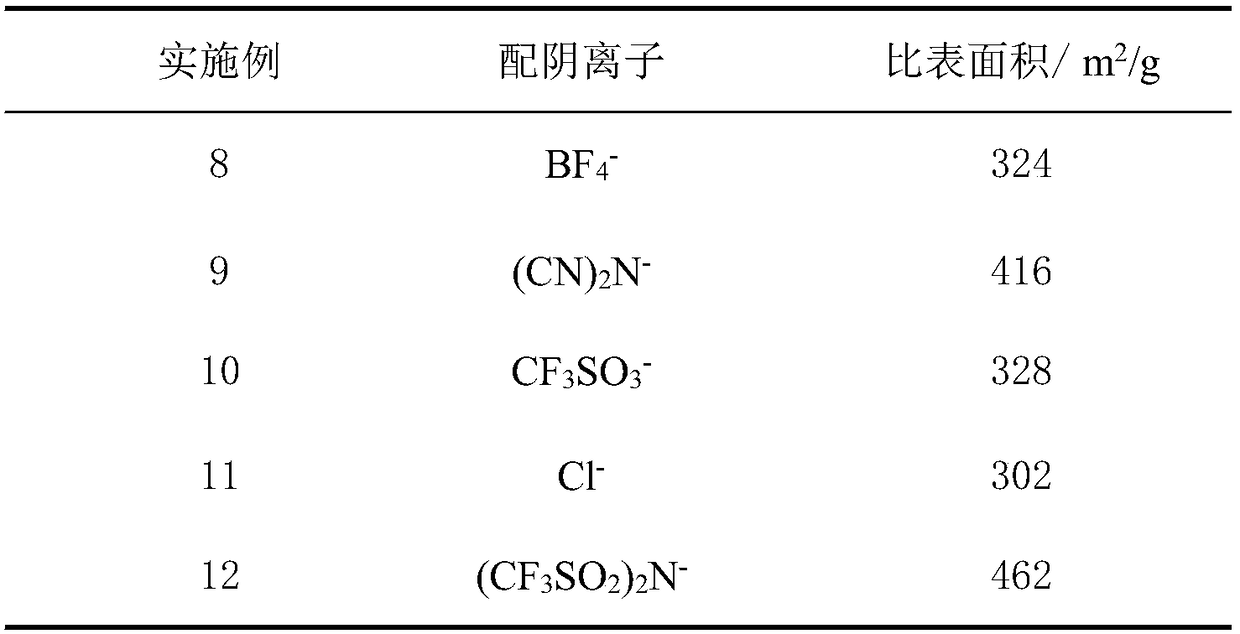

[0030] Except the following difference, all the other are identical with embodiment 1, adopt the coordination anion shown in table 2 respectively.

[0031] Table 2

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com