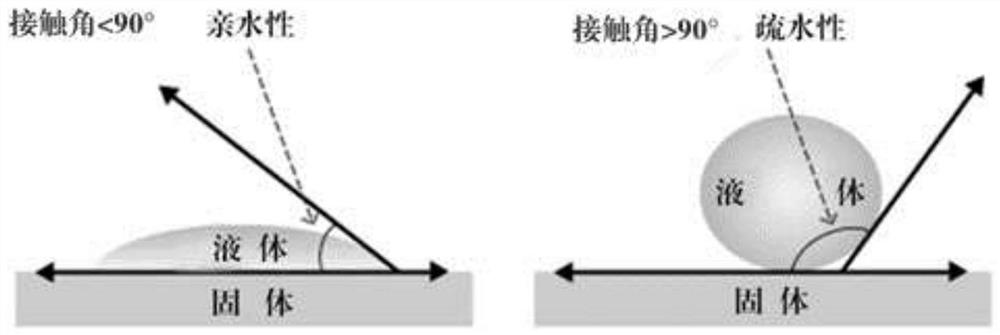

A kind of superhydrophobic vitrified coating and preparation method thereof

A ceramic and superhydrophobic technology, applied in the field of applied chemistry, can solve the problems of low thermal stability and mechanical stability of organic materials, reduce the surface free energy of metal materials, and lose superhydrophobicity, etc., so as to improve service performance and avoid high temperature Effect of sintering and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

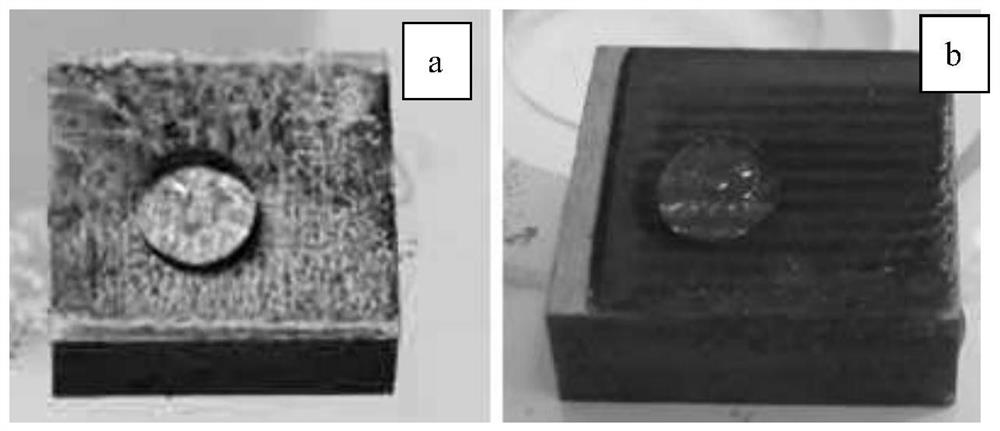

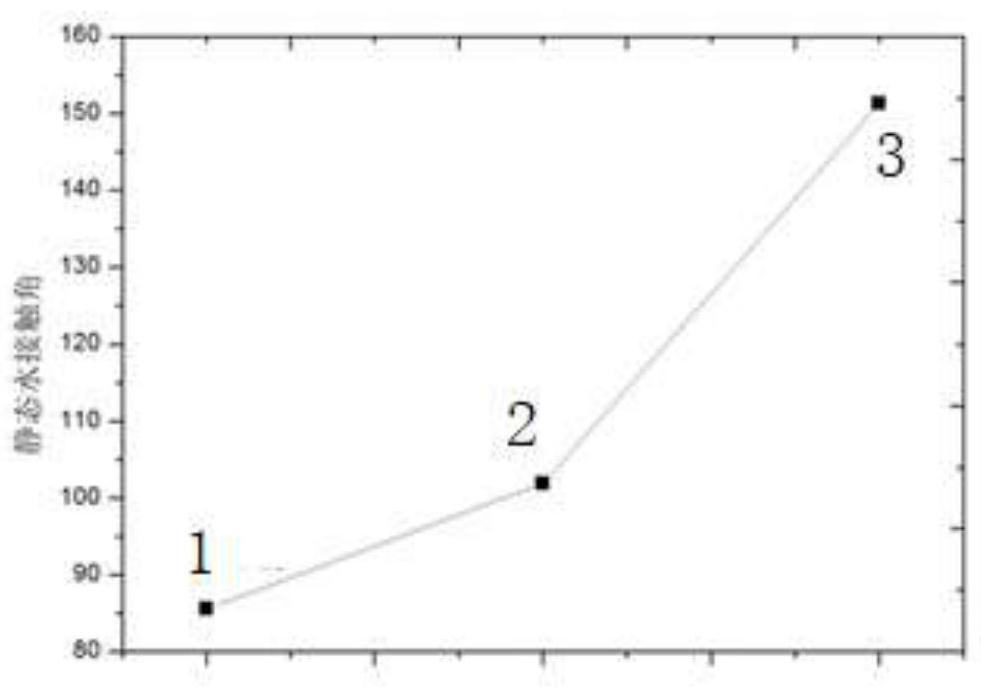

Examples

Embodiment 1

[0048] The precursor component of this example is polysilazane (Polysilazane 1, PSZ1), a low-viscosity liquid organopolysilazane polymer with an average molecular weight of 600-1000 and composed of repeating Si-N units. The laser is DLS-3000C Continuous high-power semiconductor laser, laser wavelength 980nm, maximum output power 3KW, spot size 14mm×2.5mm, working distance 310±10mm.

[0049] The preparation method of above-mentioned ceramic coating is made up of the following steps:

[0050] (1) Sandblast the substrate (a 45 steel sample block with a length of 20mm, a width of 20mm, and a height of 5mm), then clean it with ethanol and acetone, and dry it for later use.

[0051] (2) the xylene solution of 30% organic polymer ceramic precursor PSZ1 is coated on the substrate surface, then add filler ferrocene, make ferrocene in the total material system (containing 30% organic polymer ceramic precursor PSZ1 The mass fraction in xylene solution+filler) is 15%, and the solvent is ...

Embodiment 2

[0055] The precursor component of this example is PSZ2 (Polysilazane2), a low-viscosity liquid organic polysilazane polymer with an average molecular weight of 500-900 and composed of repeating Si-N units. The laser is a DLS-3000C continuous high-power semiconductor laser , The laser wavelength is 980nm, the maximum output power is 3KW, the spot size is 14mm×2.5mm, and the working distance is 310mm±10mm.

[0056] The preparation method of above-mentioned ceramic coating is made up of the following steps:

[0057] (1) Sandblast the substrate (a 45 steel sample block with a length of 20mm, a width of 20mm, and a height of 5mm), then clean it with ethanol and acetone, and dry it for later use.

[0058] (2) Coating the xylene solution of 50% organic polymer ceramic precursor PSZ2 on the substrate surface, then adding filler tetrabutyl titanate, making tetrabutyl titanate in the total material system (containing 30% organic polymer ceramics The mass fraction of the precursor PSZ2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com