Method for preparing methylacrolein

A technology for methacrolein and propionaldehyde, which is applied in the fields of condensation preparation of carbonyl compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc. Low problems, to achieve the effect of continuous operation, improve efficiency, and increase the utilization rate of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Method for preparing methacrolein:

[0066] (1) Under the protection of nitrogen, the vacuum-treated 1g of nano-SiO with a particle size of 50nm 2 Add 12mL of toluene, 0.4g of methyltrimethoxysilane and 0.3g of triethylamine in sequence, then reflux and stir at 70°C for 4h, after centrifugation, wash with toluene 4 times, ethanol twice, and dry at 120°C 12h to obtain surface-modified nano-SiO 2 ;

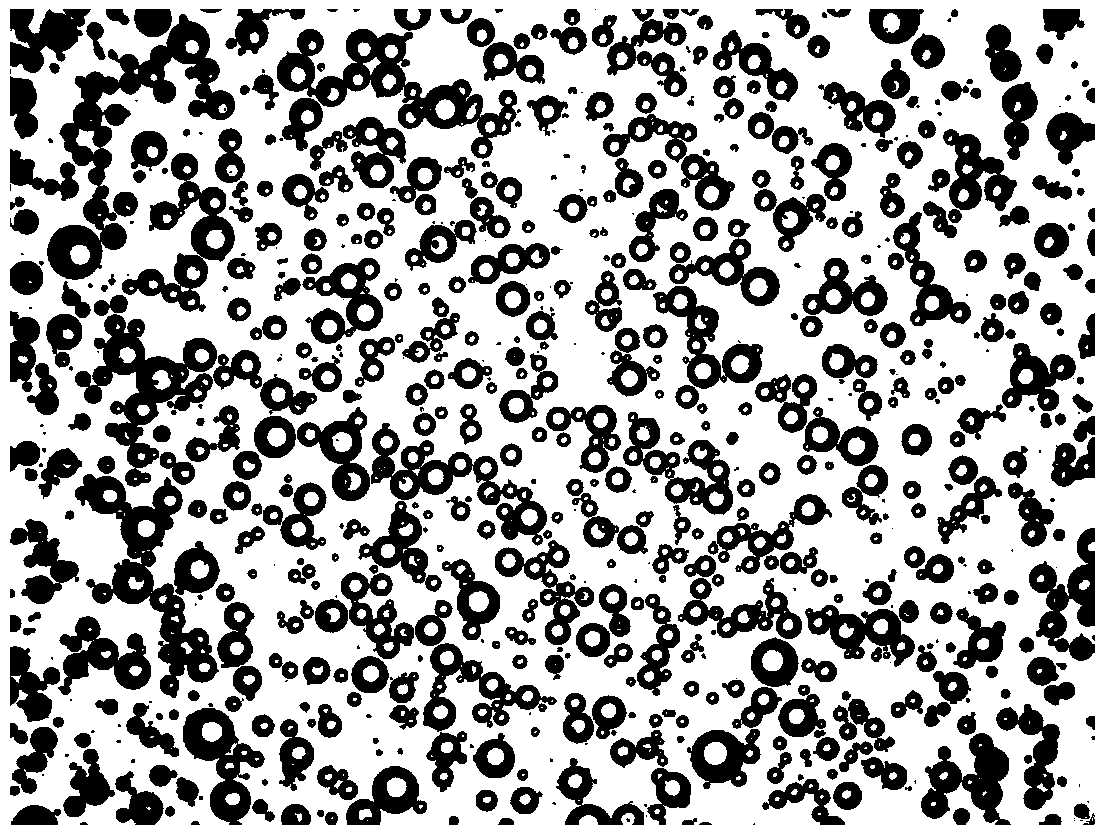

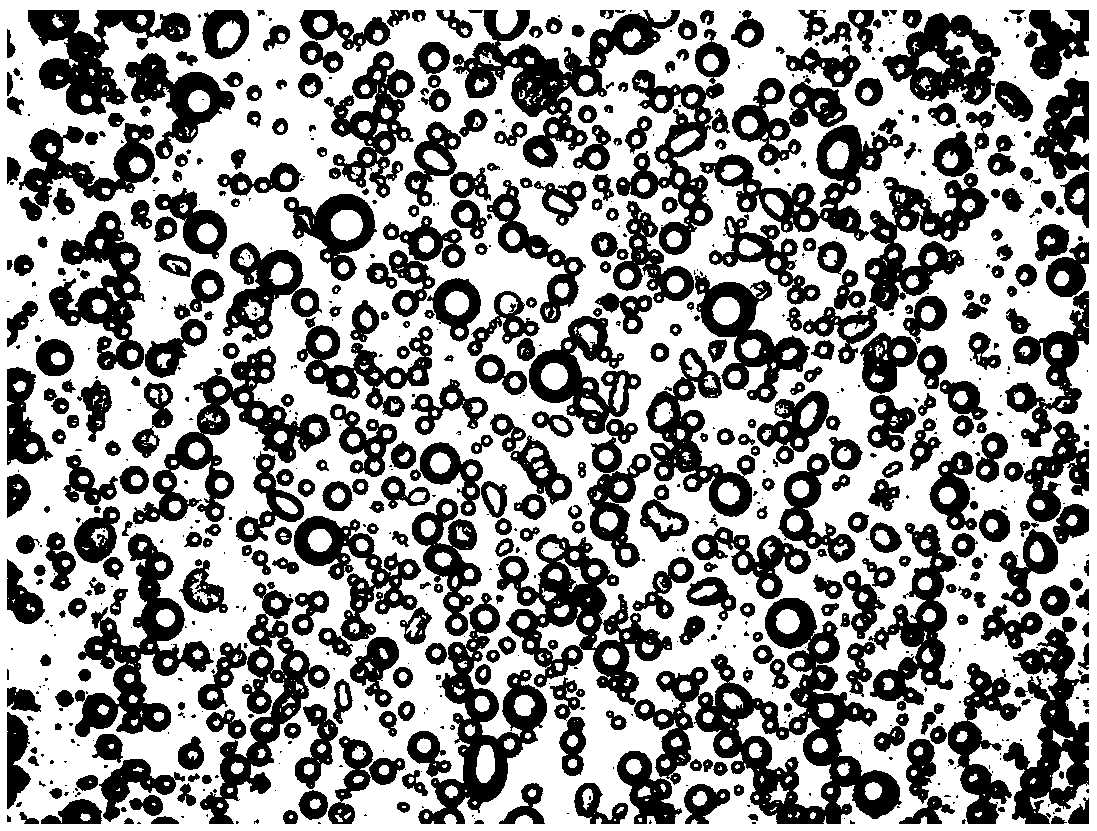

[0067] (2) the surface-modified nano-SiO obtained by 0.12g step (1) 2 Ultrasonic dispersion in 5mL cyclohexane, adding 3mL diethanolamine acetate aqueous solution with a concentration of 0.1mol / L, vortex mixing to obtain Pickering emulsion;

[0068] (3) Add the Pickering emulsion that step (2) obtains in the fixed-bed reaction column, and the static loading is 4cm 3 , feed a reaction material containing formaldehyde and propionaldehyde at 45°C to react to prepare methacrolein, the molar ratio of formaldehyde and propionaldehyde is 1.1:1, and the concentration of propional...

Embodiment 2

[0072] In this example, the amount of methyltrimethoxysilane added in Example 1 was replaced by 0.33 g, without ethanol washing, and an equal volume of diethanolamine acetate aqueous solution was replaced by diethanolamine ethyl alcohol with a concentration of 0.5mol / L. brine solution; replace the space velocity of the reaction with 0.375h -1 ; Other conditions are exactly the same as in Example 1.

[0073] The average conversion rate of propionaldehyde in this embodiment is 100%, and the yield of methacrolein is 90%.

Embodiment 3

[0075] Compared with Example 1, this example does not carry out ethanol washing, replaces an equal volume of diethanolamine acetate aqueous solution with a concentration of 2mol / L diethanolamine acetate aqueous solution, and replaces the space velocity of the reaction with 0.375h -1 ; Other conditions are exactly the same as in Example 1.

[0076] The average conversion rate of propionaldehyde in this embodiment is 94%, and the yield of methacrolein is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com