Reactive dyeing assistant of linen fabric and application

A linen fabric and reactive dye technology, applied in the field of textile printing and dyeing, can solve the problems of destroying the ecological environment, loss of cultivation ability of the land, environmental pollution of printing and dyeing wastewater, etc., and achieve the effects of slowing down the cracking rate, less damage, and improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

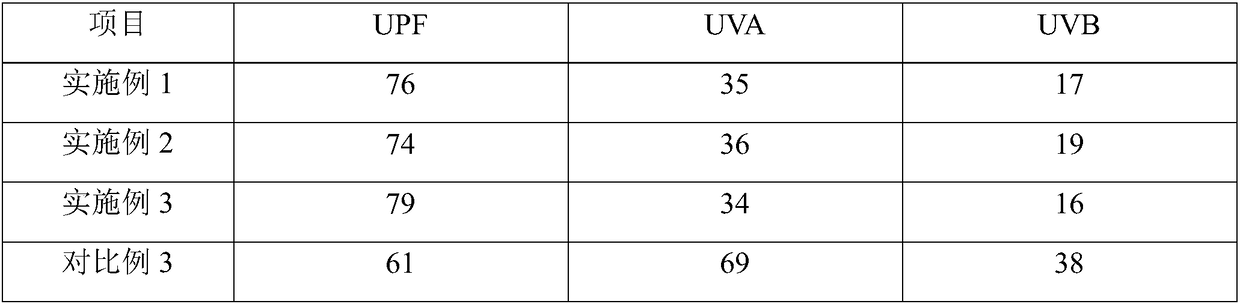

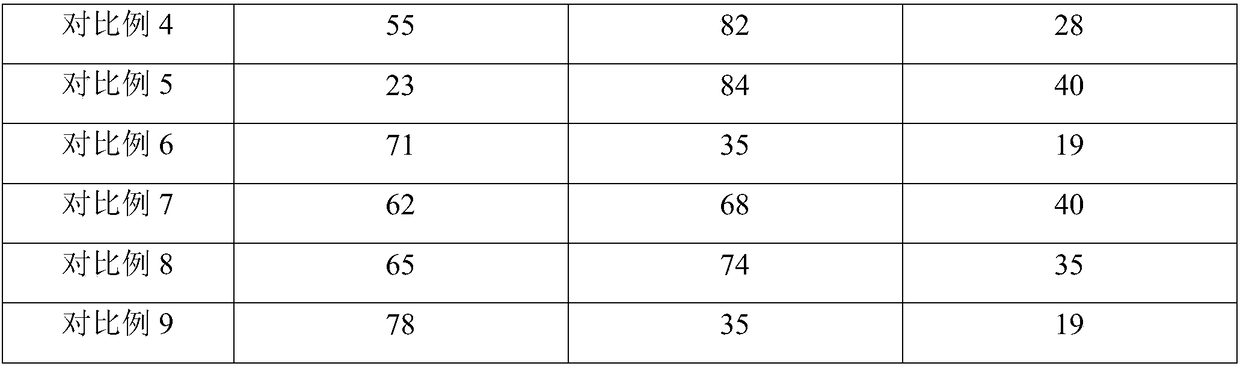

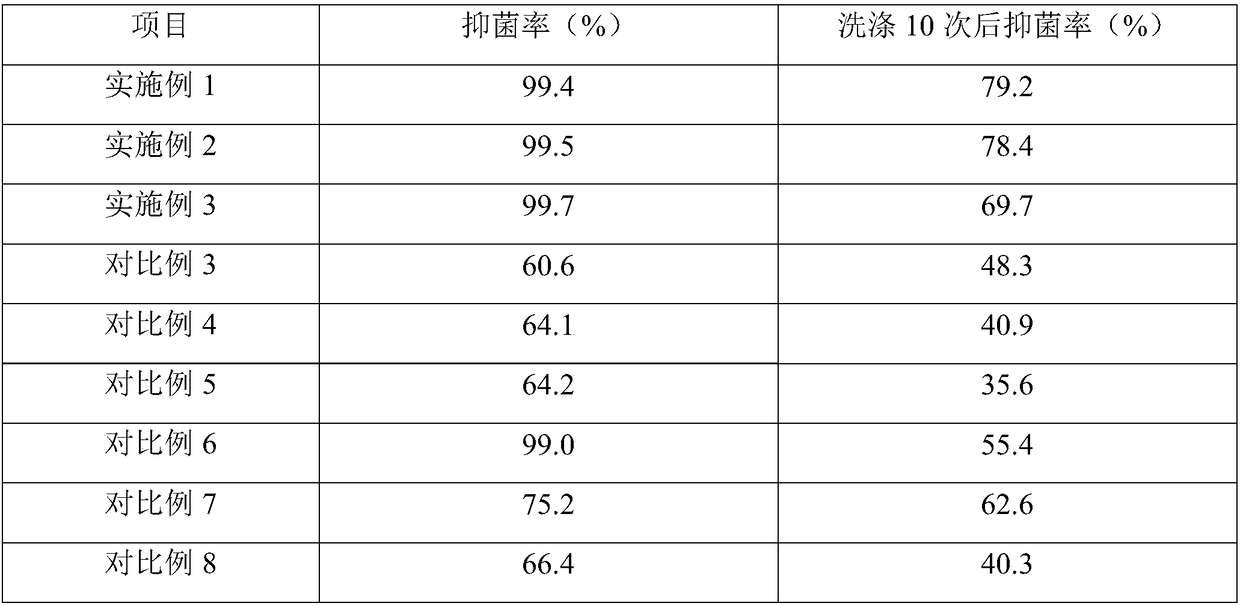

Embodiment 1

[0027]A reactive dyeing auxiliary for linen fabrics, comprising a pretreatment agent, a dyeing accelerator, and a color-fixing agent. The concentration of each component in the pretreatment agent is laccase 13U / L, xylanase 26U / L, pectinase 29U / L, nonionic surfactant mass fraction 0.2g / L, EDTA mass fraction 0.3g / L; The dyeing accelerator is composed of the following raw materials in parts by weight: 5 parts of quaternary ammonium cationic polyacrylamide, 5 parts of nano-degraded chitosan, 5 parts of graphene oxide, 0.5 parts of branched isomeric alcohol ether, rare earth GdCl 3 0.5 parts, 2 parts of potassium sodium tartrate, 40 parts of deionized water; the color fixing agent is composed of the following raw materials in parts by weight: 15 parts of biomass-based water-based polyurethane microemulsion, 10 parts of amino silicone oil, and 45 parts of deionized water.

[0028] Further, the nonionic surfactants are Pingpinga O and JFC.

[0029] Further, the particle size range ...

Embodiment 2

[0037] A reactive dyeing auxiliary for linen fabrics, comprising a pretreatment agent, a dyeing accelerator, and a color-fixing agent. The concentration of each component in the pretreatment agent is laccase 14U / L, xylanase 27U / L, pectinase 30U / L, nonionic surfactant mass fraction 0.25g / L, EDTA mass fraction 0.4g / L; The dyeing accelerator is composed of the following raw materials in parts by weight: 8 parts of quaternary ammonium cationic polyacrylamide, 8 parts of nano-degraded chitosan, 9 parts of graphene oxide, 0.8 parts of branched isomeric alcohol ether, rare earth GdCl 3 0.6 parts, 3 parts of potassium sodium tartrate, 50 parts of deionized water; the color fixing agent is composed of the following raw materials in parts by weight: 25 parts of biomass-based water-based polyurethane microemulsion, 15 parts of amino silicone oil, and 55 parts of deionized water.

[0038] Further, the nonionic surfactant is bugongsaponin.

[0039] Further, the particle size range of the...

Embodiment 3

[0047] A reactive dyeing auxiliary for linen fabrics, comprising a pretreatment agent, a dyeing accelerator, and a color-fixing agent. The concentration of each component in the pretreatment agent is laccase 15U / L, xylanase 28U / L, pectinase 31U / L, nonionic surfactant mass fraction 0.3g / L, EDTA mass fraction 0.5g / L; The dyeing accelerator is composed of the following raw materials in parts by weight: 10 parts of quaternary ammonium cationic polyacrylamide, 10 parts of nano-degraded chitosan, 12 parts of graphene oxide, 1 part of branched isomeric alcohol ether, rare earth GdCl 3 0.8 parts, 5 parts of potassium sodium tartrate, 60 parts of deionized water; the color fixing agent is composed of the following raw materials in parts by weight: 35 parts of biomass-based water-based polyurethane microemulsion, 20 parts of amino silicone oil, and 65 parts of deionized water.

[0048] Further, the nonionic surfactant is Pingpinga O, JFC, and bugongsaponin.

[0049] Further, the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com