A kind of preparation method of amino acid surfactant

A technology for surfactants and amino acids, which is applied in the field of preparation of high-purity amino acid surfactants, can solve problems affecting the quality of amino acid surfactants, low yield of amino acid surfactants, and difficult industrialization control, etc., and achieves excellent appearance and color. Excellent product appearance, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention provides a kind of preparation method of high-purity amino acid surfactant, and the technical scheme that it adopts is as follows:

[0019] A kind of preparation method of high-purity amino acid surfactant, concrete steps are as follows:

[0020] (1) At room temperature, add fatty acid and catalyst into a four-necked flask equipped with a thermometer, a stirrer and an exhaust gas recovery device, slowly raise the temperature to 50-70 degrees, add thionyl chloride dropwise or pass through phosgene, and finish adding After reacting the materials for 3-6 hours, fatty acyl chlorides are obtained;

[0021] (2) At room temperature, add amino acid and caustic solution to a four-necked flask with a thermometer and a stirrer, control the pH range to 10-12 by controlling the concentration of caustic, cool to 10-20 degrees through cold water, and simultaneously Add fatty acid chloride and caustic alkali solution dropwise, keep the pH constant during the drop...

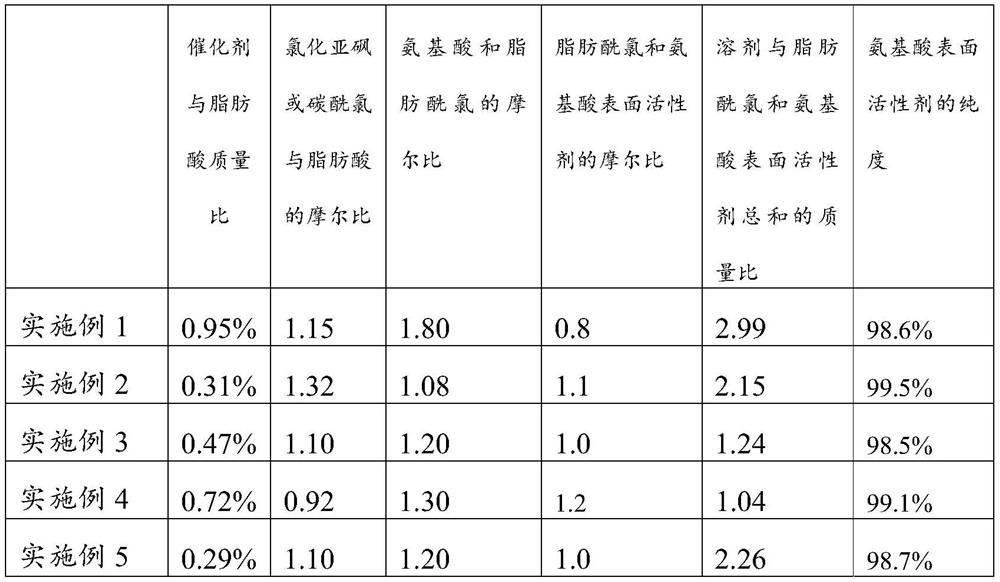

Embodiment 1

[0032] (1) At room temperature, add 150 g of myristic acid and 1.43 g of catalyst into a 500 mL four-neck flask equipped with a thermometer, a stirrer and a tail gas recovery device, slowly raise the temperature to 60 degrees, add 90 g of thionyl chloride dropwise, and finish adding After the material was reacted for 4 hours, myristoyl chloride was obtained; (2) at room temperature, 43.9 g of glycine and sodium hydroxide solution (pH 10.2) were added to a 500 mL four-neck flask inserted with a thermometer and a stirrer, and cooled to 15 At the same time, 80g of myristoyl chloride and 27% sodium hydroxide solution were added dropwise to keep the pH constant, and reacted for 5 hours after adding the materials; (3) adding sulfuric acid to adjust the pH to 1.7, then adding cold water, filtering and drying to obtain myristoyl Glycine, 98.6% pure.

[0033] Catalyst preparation: at room temperature, nitrogen gas was continuously introduced, and myristoyl chloride 20g and chloroform 9...

Embodiment 2

[0035] (1) At room temperature, add 160 g of coconut oil fatty acid and 0.5 g of catalyst in a 500 mL four-neck flask inserted with a thermometer, a stirrer and a tail gas recovery device, slowly heat up to 55 degrees, add 73 g of thionyl chloride dropwise, and finish adding After the material was reacted for 5 hours, cocoyl chloride was obtained; (2) at room temperature, 48.4 g of sodium glutamate and sodium hydroxide solution (pH 11.6) were added in a four-necked flask inserted with a thermometer and agitator, and the temperature was lowered by cold water To 20 degrees, dropwise add cocoyl chloride 86g and 25% sodium hydroxide solution at the same time, keep the pH constant, and react for 4 hours after adding the materials; (3) adjust the pH to 1 by adding phosphoric acid, then add cold water, filter and dry to obtain Cocoyl glutamic acid, 99.5% pure.

[0036] Catalyst preparation: at room temperature, continue to feed nitrogen, add cocoyl chloride 22g and dichloromethane 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com