Preparation method and application of calcium silicate adsorbing material

An adsorption material, calcium silicate technology, applied in chemical instruments and methods, adsorption water/sewage treatment, silicon compounds, etc., can solve the problems of high cost of calcium silicate materials, limited adsorption capacity, difficulty in popularization and application, etc., and achieve raw materials Sufficient sources, low production costs, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

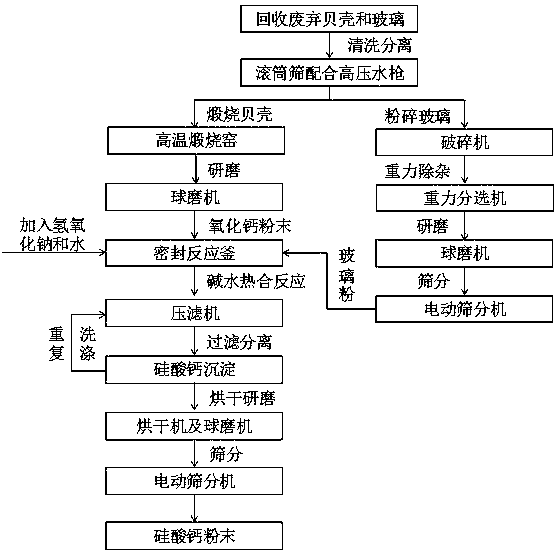

Method used

Image

Examples

Embodiment 1

[0049] The preparation of embodiment 1 calcium silicate adsorption material

[0050] (1) Recover discarded oyster shells and glass, transport them back to the processing base, put them into a drum sieve with an aperture of 13mm, and build a high-pressure water gun with a flushing pressure of 700bar. Combine the drum sieve and high-pressure water gun to clean the discarded shells and glass respectively, Remove the dust and sand; put the cleaned glass into a crusher for crushing, and then load it into a gravity separator to separate lighter paper scraps, bamboo wood chips, plastics, film and film-containing glass particles Separation from the heavier glass slag to remove impurities from the glass and obtain glass slag;

[0051] (2) Put the discarded shells separated by washing into a high-temperature calcination kiln, and calcine them at 800°C for 3 hours. The main component of the shells, CaCO 3 Calcined into CaO, the reaction is as follows:

[0052] CaCO 3 →CaO+CO 2 ↑

[...

Embodiment 2

[0056] The preparation of embodiment 2 calcium silicate adsorption material

[0057] (1) Recover discarded oyster shells and glass, transport them back to the processing base, put them into a drum sieve with an aperture of 13mm, and build a high-pressure water gun with a flushing pressure of 700bar. Combine the drum sieve and high-pressure water gun to clean the discarded shells and glass respectively, Remove the dust and sand; put the cleaned glass into a crusher for crushing, and then load it into a gravity separator to separate lighter paper scraps, bamboo wood chips, plastics, film and film-containing glass particles Separation from the heavier glass slag to remove impurities from the glass and obtain glass slag;

[0058] (2) Put the discarded shells separated by washing into a high-temperature calcination kiln, and calcine them at 800°C for 3 hours. The main component of the shells, CaCO 3 Calcined into CaO, the reaction is as follows:

[0059] CaCO 3 →CaO+CO 2 ↑

[...

Embodiment 3

[0063] The preparation of embodiment 3 calcium silicate adsorption material

[0064] (1) Recover discarded oyster shells and glass, transport them back to the processing base, put them into a drum sieve with an aperture of 13mm, and build a high-pressure water gun with a flushing pressure of 700bar. Combine the drum sieve and high-pressure water gun to clean the discarded shells and glass respectively, Remove the dust and sand; put the cleaned glass into a crusher for crushing, and then load it into a gravity separator to separate lighter paper scraps, bamboo wood chips, plastics, film and film-containing glass particles Separation from the heavier glass slag to remove impurities from the glass and obtain glass slag;

[0065] (2) Put the discarded shells separated by washing into a high-temperature calcination kiln, and calcine them at 800°C for 3 hours. The main component of the shells, CaCO 3 Calcined into CaO, the reaction is as follows:

[0066] CaCO 3 →CaO+CO 2 ↑

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com