Method for electrically adsorbing metal ions through porous carbon material prepared from PVC waste plastic

A metal ion, electro-adsorption technology, applied in separation methods, chemical instruments and methods, carbon preparation/purification, etc., can solve the problem of less metal ion treatment, and achieve the effects of low cost, simple operation and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

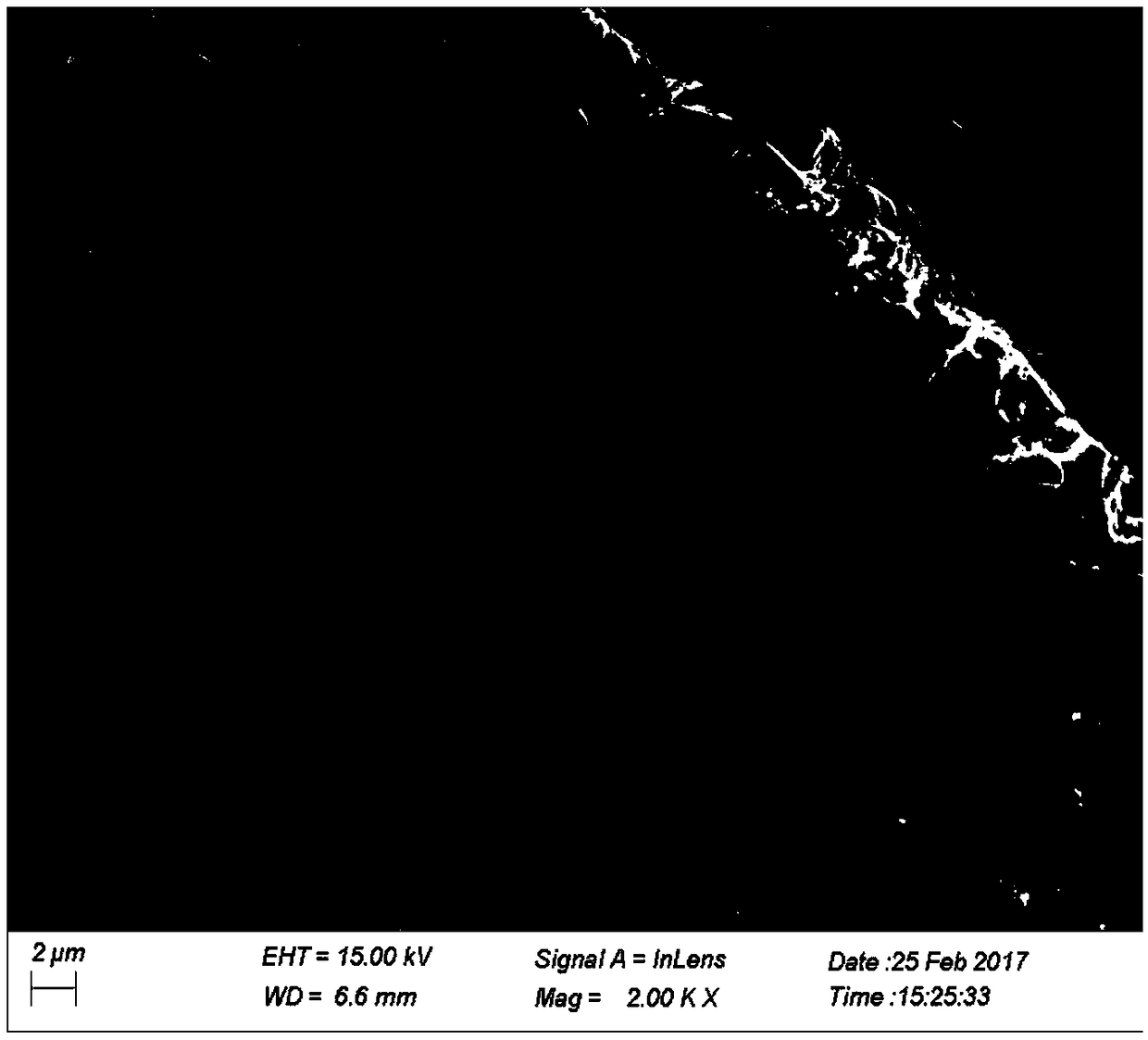

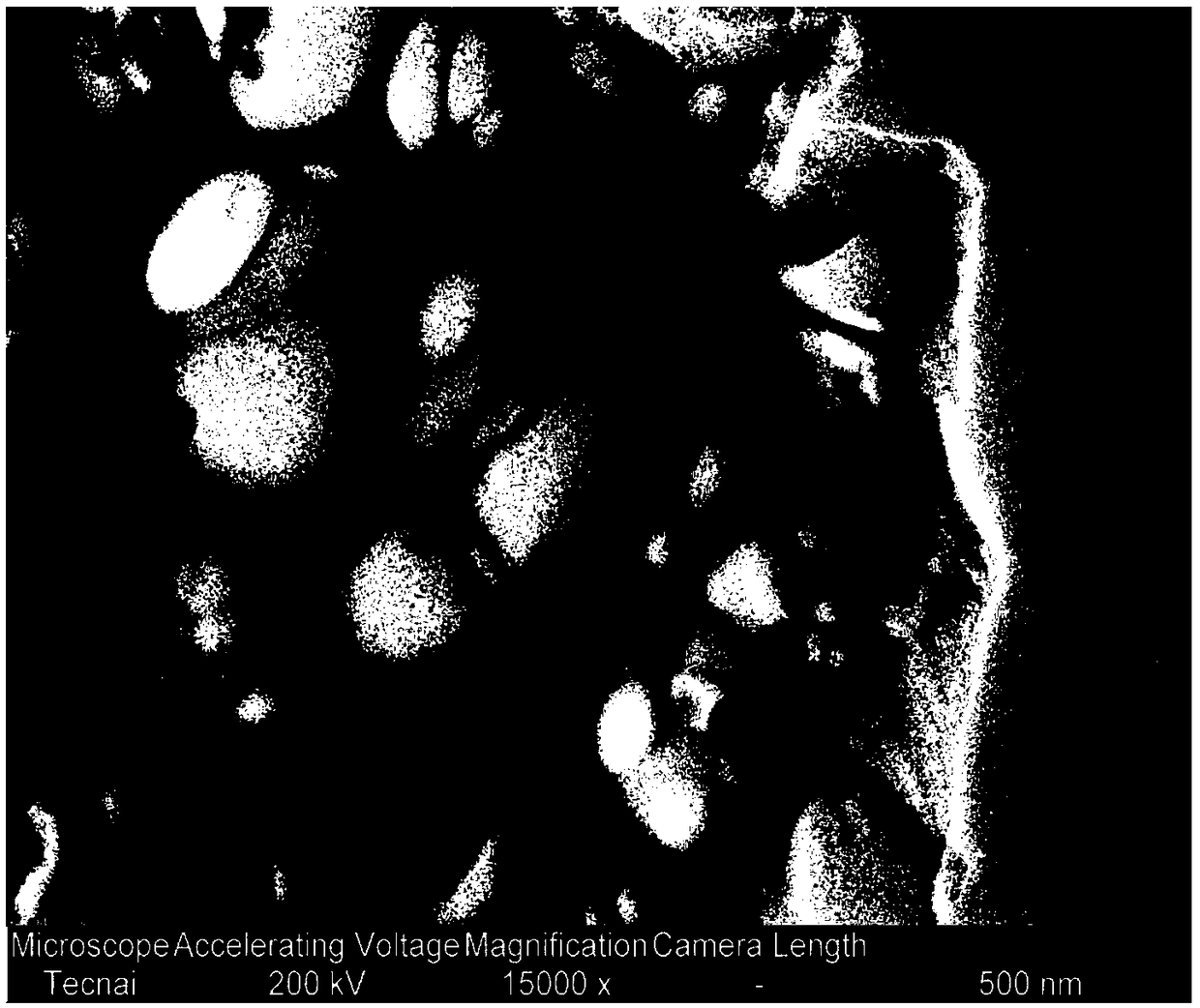

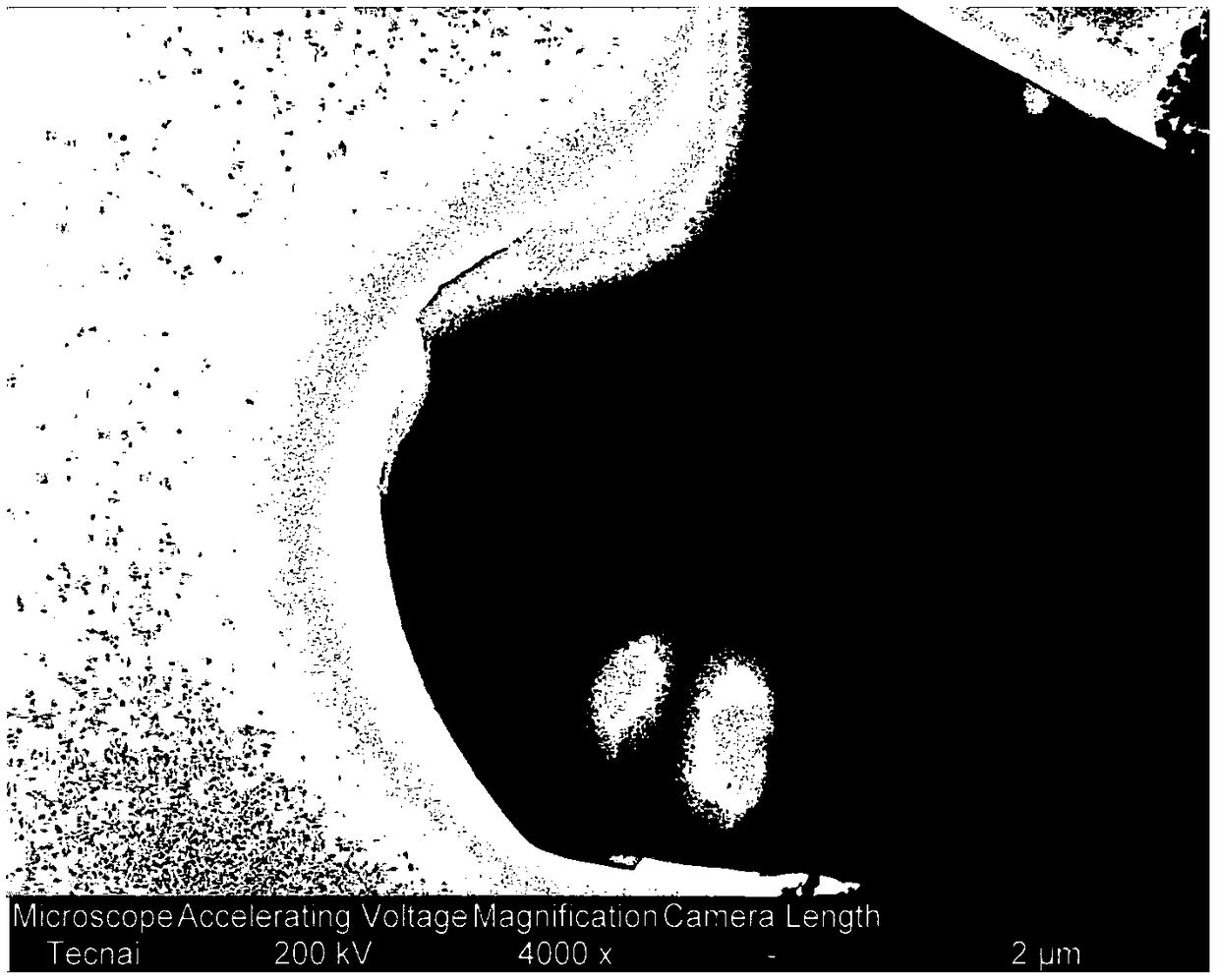

[0043] a. Put 1.0g of shredded waste PVC file bags into 10.0mL of dimethylformamide solution, heat and stir at 60°C for 20min. The above solution was transferred to a ball mill jar, and then 2.0 g of potassium hydroxide and 1.0 g of thiourea were added to the black slurry obtained by ball milling at room temperature for 4 hours, and dried in an oven at 60° C. to obtain a precursor of a nitrogen-sulfur double-doped porous carbon material. The precursor prepared in Example 1 was roasted at 600°C for 2 hours in a tube furnace under the protection of an inert gas at a rate of 5-10°C / min; Dry in an oven at 80°C to obtain a porous carbon material doped with nitrogen and sulfur.

[0044] b. A variety of metal chloride aqueous solutions are respectively configured to simulate industrial wastewater. The concentration of each metal ion is 40mg / L or 1mg / L (pH=6.5-6.8). 13 microSiemens / cm;

[0045] c. Mix the porous doped carbon material, acetylene black, and binder at a ratio of 80:15:...

Embodiment 2

[0048] Synthesize a nitrogen-sulfur double-doped porous carbon material according to the method of Example 1, but configure a mixed aqueous solution of three kinds of metal chlorides (magnesium, nickel, lead) to carry out electrosorption treatment (pH=6.8), and the concentration of each metal ion is respectively 20mg / L, the conductivity of the above simulated wastewater was measured to be ~250 microsiemens / cm; a voltage of 1.4V was applied for electrosorption, the flow rate of the solution was 25ml / min, and desorption was achieved by applying a reverse voltage of 1.4V; electrosorption and desorption During the process, take 1ml of the treated mixed solution from the beaker every 1 hour to the plasma emission spectrometer (ICP) for quantitative analysis of the metal element content, and obtain the concentration changes of various metal ions in the mixed solution during the adsorption and desorption process . Depend on Figure 13 and 14 It can be seen that magnesium ions still...

Embodiment 3

[0050] Except that thiourea becomes dimethyl sulfoxide, other is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com