Post-operation absorbable anti-adhesion material for cardiac surgery and film prepared from material

A post-surgical, anti-adhesion technology, applied in the field of medical materials and films prepared therefrom, can solve the problems of poor flexibility and stretch index, too fast in vivo degradation rate, uncontrollable mechanical properties, etc., and achieves flexible hand feel and good water permeability , no cytotoxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

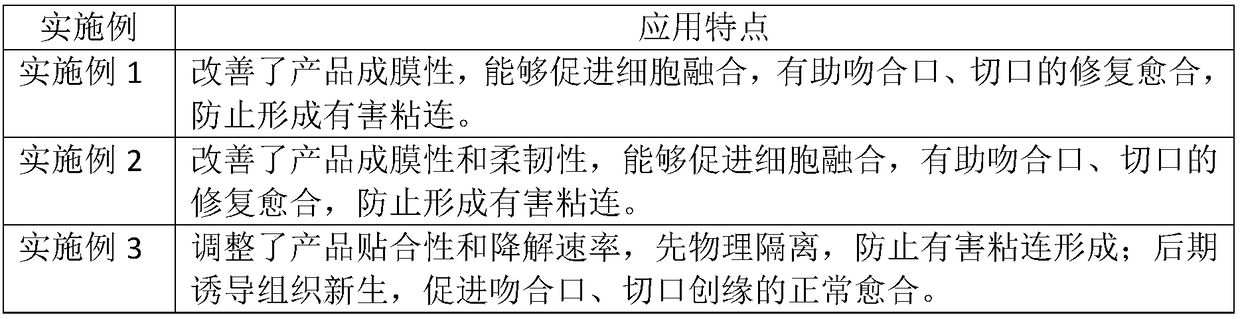

Embodiment 1

[0031] Select medium-viscosity chitosan with a viscosity of 0.25 Pa·s and a degree of deacetylation of 95%, dissolve chitosan in 15 wt% acetic acid solution, and prepare a chitosan solution with a weight percentage of 15 wt%. Take 45 kg of chitosan liquid; 5 kg of gelatin, 15 kg of glycerin, 10 kg of collagen, 5 kg of hyaluronic acid, and 10 kg of sodium carboxymethyl cellulose; react at 100°C for 55 hours, cool down to obtain chitosan sugar reaction solution. Dissolving 10 kg of silk fibroin in 40 kg of 25 wt% ethanol solution, filtering, centrifuging, and removing the insoluble part to obtain a silk fibroin stock solution.

[0032] With 15wt% acetic acid solution, the concentration of the mixed solution of chitosan reaction solution and silk fibroin stock solution is adjusted to 5wt%, filtered, and injected into the mould after leaving standstill for 10 hours for defoaming; The volume ratio is 1000:15 to make a coagulation solution, and then put the mold into the coagulatio...

Embodiment 2

[0040] Dissolve medium viscosity chitosan with a viscosity value of 0.65 Pa·s and chitosan with a deacetylation degree of 85% in 20 wt% acetic acid solution to form a chitosan solution with a weight percentage of 20 wt%. Select 45 kg of chitosan liquid, 10 kg of gelatin, 10 kg of glycerin, 10 kg of collagen, 10 kg of hyaluronic acid, and 5 kg of sodium carboxymethyl cellulose; react at 90°C for 85 hours, cool down, and obtain chitosan sugar reaction solution. Dissolving 10 kg of silk fibroin in 40 kg of 20 wt% ethanol solution, filtering, centrifuging, and removing the insoluble part to obtain a silk fibroin stock solution.

[0041] Use 20wt% acetic acid solution to adjust the concentration of the mixed solution of chitosan reaction solution and silk fibroin stock solution to 20wt%, filter, leave to stand for 5 hours after defoaming, inject mold; the sodium hydroxide of absolute ethanol, 15wt% concentration Make a coagulation solution at a volume ratio of 1000:15, then put th...

Embodiment 3

[0044] Choose medium-viscosity chitosan with a viscosity value of 0.35Pa·s, and a degree of deacetylation of 92%. Dissolve chitosan in 10wt% acetic acid solution to configure a chitosan solution with a weight percentage of 15wt%. Choose 45 kg of shell Polysaccharide liquid, 5 kg of gelatin, 25 kg of glycerin, 10 kg of collagen, 5 kg of hyaluronic acid, 5 kg of sodium carboxymethyl cellulose; react at 95°C for 70 hours, cool down to obtain chitosan reaction liquid. Dissolving 5 kg of silk fibroin in 15wt% ethanol solution, filtering, centrifuging, and removing the insoluble part to obtain the silk fibroin stock solution.

[0045] Use 10wt% acetic acid solution to adjust the concentration of the mixed solution of chitosan reaction solution and silk fibroin stock solution to 15wt%, filter, leave to stand for 15 hours after defoaming, inject mold; the sodium hydroxide of absolute ethanol, 10wt% concentration Make a coagulation solution at a volume ratio of 1000:20, then put the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com