The method and application of preparing high ester bond humic acid preparation by Clostridium beijerinckii

A technology for Clostridium beijerinckii and Clostridium beijerinckii-containing, applied in the directions of microorganism-based methods, biochemical equipment and methods, applications, etc., can solve the problems that the time and location of product release cannot be guaranteed to be controllable and unreachable, etc. To achieve the effect of whole intestinal bacteriostasis and energy supply, promote smooth progress and save separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

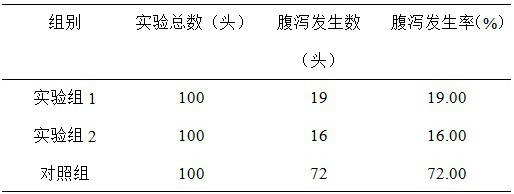

Embodiment 1

[0025] Embodiment 1: a kind of preparation method of high ester bond humic acid preparation, it comprises the steps:

[0026] The first step is to make a seed solution containing Clostridium bejejerinckii, in which the concentration of the bacteria solution is 0.5×10 8 -1.0×10 8 CFU / ml; Clostridium beijerinckii is the preservation number CCTCC No. M2014384 Clostridium beijerinjecki SE-2.

[0027] Seed medium (TYA medium): glucose 40 g, beef extract 2 g, yeast powder 2 g, peptone 6 g, CH 3 COONH 4 3 g, KH 2 PO 4 0.5 g, MgSO 4 ·7H 2 O 0.2 g, FeSO 4 ·7H 2 O 0.01 g, distilled water 1000 mL, pH 6.5, autoclave at 121 ℃ for 15 min, blow with sterile nitrogen for 5 min to drive out oxygen.

[0028] The second step is to prepare butyric acid production fermentation medium, specifically: basic fermentation medium: K 2 HPO 4 0.5 g, KH 2 PO 4 0.5 g, CH 3 COONH 4 2.2 g, MgSO 4 ·7H 2 O 0.2 g, MnSO 4 ·H 2 O 0.01 g, NaCl 0.01 g, FeSO 4 ·7H 2 O 0.01 g, thiamine (thiamine...

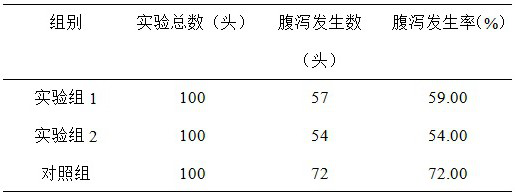

Embodiment 2

[0035] Embodiment 2: a kind of preparation method of high ester bond humic acid preparation, it comprises the steps:

[0036] The first step, second step, with embodiment 1.

[0037] In the third step, sodium humate was added to the fermentation medium at a rate of 7 g / L.

[0038] In the fourth step, the sterilization of the fermentation medium in the fermenter is completed, and after cooling down to room temperature, lipase is added to the fermenter at a mass ratio of lipase to sodium humate of 1:3.

[0039] In the fifth step, the Clostridium beijerinckii seed solution and the fermentation medium in the first step are added to the fermentation medium at a volume ratio of 2% by a peristaltic pump, and cultured with stirring at 40°C and 80 rpm.

[0040] In the sixth step, 200g / L xylose is added into the fermenter using a peristaltic pump to maintain the concentration of xylose in the fermentation broth at 20g / L.

[0041] Step 7: At the end of the 96th hour of fermentation, th...

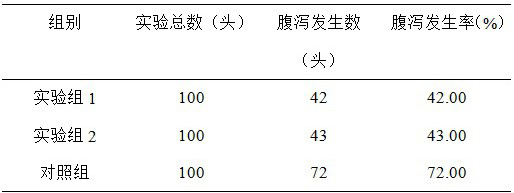

Embodiment 3

[0043] Embodiment 3: a kind of preparation method of high ester bond humic acid preparation, it comprises the steps:

[0044] The first step, second step, with embodiment 1.

[0045] In the third step, sodium humate was added to the fermentation medium at a rate of 10 g / L.

[0046] In the fourth step, the fermentation medium in the fermenter is sterilized, and after cooling down to room temperature, lipase is added to the fermenter at a mass ratio of lipase to sodium humate of 1:1.

[0047] In the fifth step, the Clostridium beijerinckii seed solution and the fermentation medium in the first step are added to the fermentation medium at a volume ratio of 2% using a peristaltic pump, and cultured at 42°C and 100 rpm with stirring.

[0048] In the sixth step, 200g / L xylose is added into the fermenter using a peristaltic pump to maintain the concentration of xylose in the fermentation broth at 20g / L.

[0049] Step 7: At the end of the 96th hour of fermentation, the fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com