Flame-retardant compression-resistant composite for glass fiber reinforced plastic septic tank and preparation method of flame-retardant compression-resistant composite

A composite material and glass tempering technology, which is applied in the field of glass fiber reinforced plastic to achieve the effects of good flame retardancy and weather resistance, improving mechanical properties and improving compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

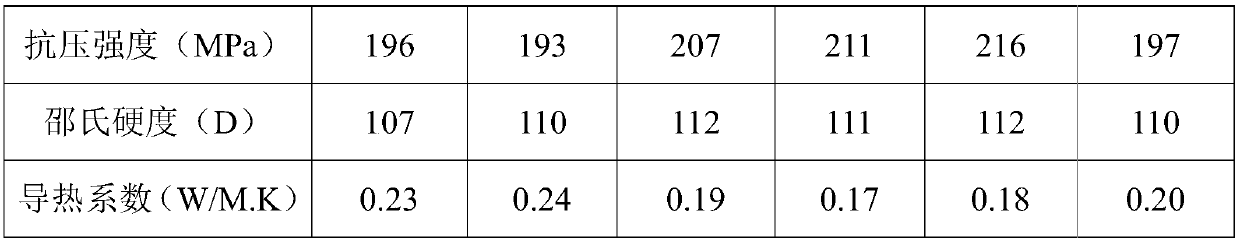

Examples

Embodiment 1

[0018] A flame-retardant and compression-resistant composite material for FRP septic tanks proposed by the present invention, its raw materials include: 100 parts of unsaturated polyester resin, 3 parts of acrylonitrile-butadiene-styrene copolymer, glass 80 parts of fiber, 3 parts of silica powder, 20 parts of bentonite, 6 parts of propylene oxide butyl ether, 3 parts of curing agent, 2 parts of accelerator, 2 parts of flame retardant, 0.5 parts of benzotriazole, butyl phthalate 0.5 part of benzyl ester, 1 part of coupling agent;

[0019] Among them, the particle size D of the silica powder is 0.01-5 μm; the flame retardant is ammonium polyphosphate, the curing agent is methyl ethyl ketone peroxide, the accelerator is cobalt naphthenate, and the coupling agent is KH550.

[0020] The present invention also proposes the preparation method of the above-mentioned flame-retardant and compression-resistant composite material for FRP septic tanks, the steps are as follows: unsaturate...

Embodiment 2

[0022] A flame-retardant and compression-resistant composite material for FRP septic tanks proposed by the present invention, its raw materials include: 100 parts of unsaturated polyester resin, 7 parts of acrylonitrile-butadiene-styrene copolymer, glass 110 parts of fiber, 7 parts of silica powder, 30 parts of bentonite, 12 parts of propylene oxide butyl ether, 7 parts of curing agent, 5 parts of accelerator, 5 parts of flame retardant, 2 parts of benzotriazole, butyl phthalate 2 parts of benzyl ester, 3 parts of coupling agent;

[0023] Among them, the particle size D of the silica powder is 0.01-5 μm; the flame retardant is aluminum hydroxide, the curing agent is methyl ethyl ketone peroxide, the accelerator is cobalt naphthenate, and the coupling agent is KH550.

[0024] The present invention also proposes the preparation method of the above-mentioned flame-retardant and compression-resistant composite material for FRP septic tanks, the steps are as follows: unsaturated po...

Embodiment 3

[0026] A flame-retardant and compression-resistant composite material for FRP septic tanks proposed by the present invention, its raw materials include: 100 parts of unsaturated polyester resin, 4 parts of acrylonitrile-butadiene-styrene copolymer, glass 100 parts of fiber, 5 parts of silica powder, 25 parts of bentonite, 10 parts of propylene oxide butyl ether, 5 parts of curing agent, 4 parts of accelerator, 3 parts of flame retardant, 1 part of benzotriazole, butyl phthalate 1 part of benzyl ester, 2 parts of coupling agent;

[0027] Wherein, bentonite is modified bentonite, and its preparation is as follows: disperse 10 parts of bentonite in water to prepare a 6% suspension, add 4 parts of 22% dodecyltrimethylammonium chloride solution to it, ultrasonically disperse for 40min, Raise the temperature to 50°C, stir for 8 hours, and the stirring speed is 200r / min. After the reaction, add concentrated hydrochloric acid to adjust the pH to 2, stir for 3 hours, and the stirring s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com