Transparent conductive substrate, preparation method thereof and application thereof

A technology of transparent conduction and transparent substrate, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., which can solve the problems of poor patterning effect, poor conductivity and light transmittance, and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

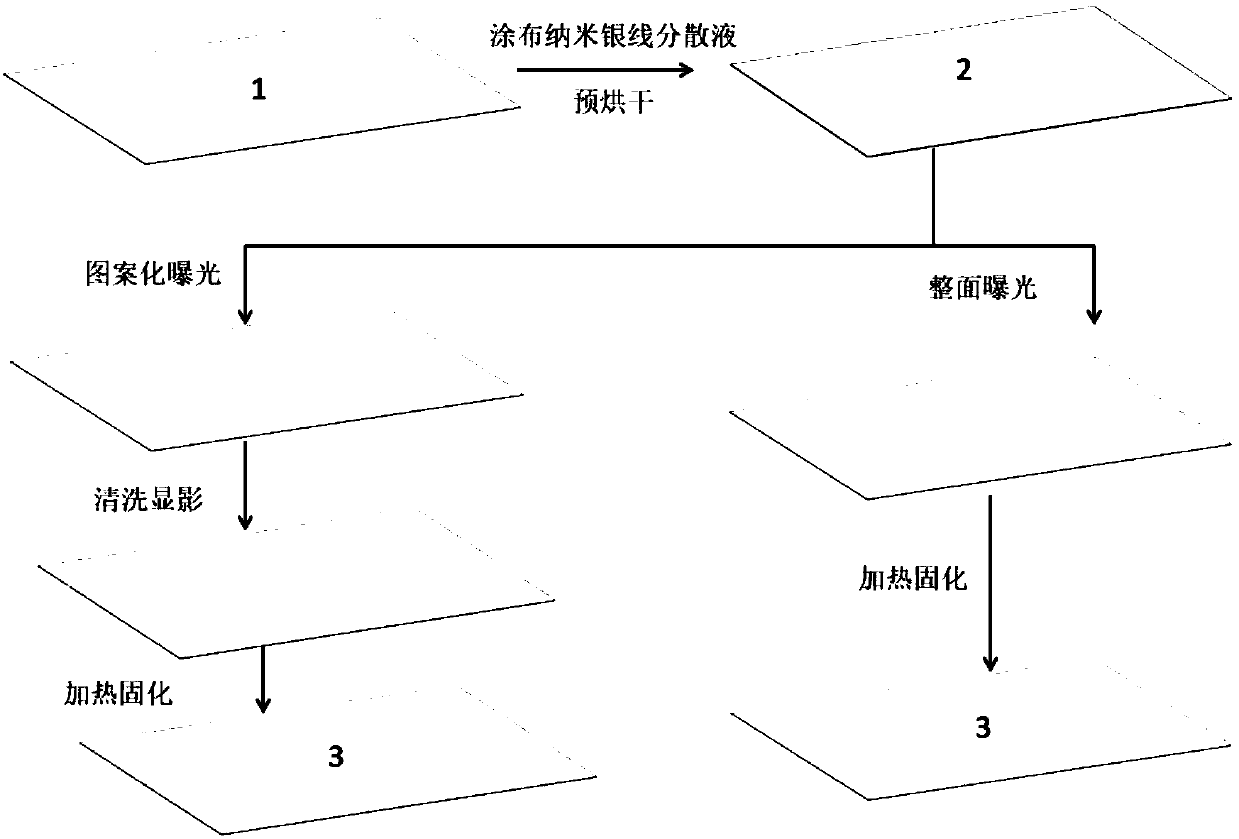

[0024] The first aspect of the present invention provides a method for preparing a transparent conductive substrate, such as figure 1 As shown, wherein, the method includes the following steps:

[0025] (a) uniformly coating the nano-silver wire dispersion on the surface of the transparent substrate 1, and pre-drying to obtain the substrate 2 coated with the nano-silver wire coating;

[0026] (b1) subjecting the base material 2 coated with the nano-silver wire coating to patterned exposure treatment, cleaning and developing, heating and curing to obtain a transparent conductive substrate 3, or

[0027] (b2) Expose the entire surface of the base material 2 coated with the silver nano wire coating, and perform heat curing to obtain a transparent conductive substrate 3 .

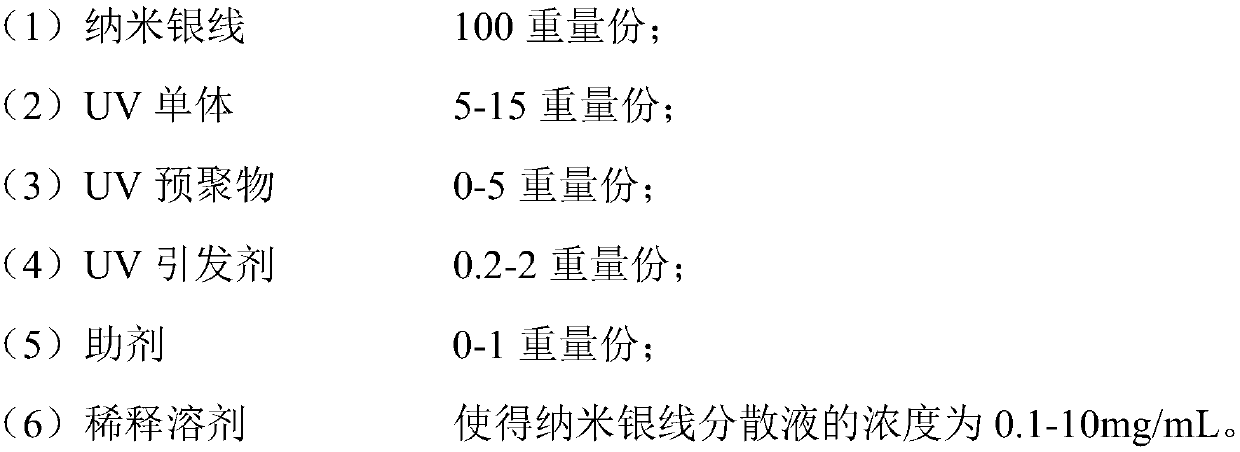

[0028] According to the method of the present invention, the silver nano wire dispersion liquid comprises the following components:

[0029]

[0030]

[0031] According to the method of the present inve...

Embodiment 1

[0060] Prepare nano-silver wire dispersion (nano-silver wire 1 is 100 parts by weight; dimethylaminoethyl methacrylate is 5 parts by weight, polyurethane acrylate is 5 parts by weight, 2,4,6-trimethylbenzoyl- Diphenylphosphine oxide is 0.5 parts by weight; the auxiliary agent is leveling agent BYK333 0.2 parts by weight; the concentration of the silver nanowire dispersion is diluted to 4 mg / mL by diluting solvent ethanol). The prepared dispersion was uniformly coated on the glass surface by slit coating, and pre-dried at 40°C for 30 minutes. The preset pattern is the whole surface conductive transparent substrate, and the direct-write UV exposure treatment is carried out through the exposure machine, and the output power of the UV lamp is 20W / cm 2 , the exposure time is 8s, and the light curing is finalized. And heated and cured at 300°C for 30 minutes to obtain a whole-surface transparent conductive substrate, see figure 1 .

[0061] The light transmittance of the visible ...

Embodiment 2

[0064] Prepare nano-silver wire dispersion liquid (nano-silver wire 1 is 100 parts by weight; acryloyl morpholine (ACMO) is 15 parts by weight, polyester acrylate is 2 parts by weight; 4-dimethylamino-ethyl benzoate is 1.5 parts by weight; parts by weight; the auxiliary agent is the adhesion promoter BYK45100.4 parts by weight; the concentration of the silver nanowire dispersion is diluted to 0.25 mg / mL by using the diluting solvent propylene glycol methyl ether. The prepared dispersion liquid was uniformly coated on the surface of polyethylene terephthalate (PET) film by slit coating method, and pre-dried at 80° C. for 10 minutes. The preset pattern is selectively exposed through a maskless exposure machine, the exposure time is 3s, and the preset pattern is photocured and finalized. Use tert-butanol to clean and develop the transparent substrate, wash off the unexposed coating, heat and dry it, and heat and cure it at 100°C for 70 minutes to obtain a transparent conductive s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com