Method for preparing novel inorganic hole transport layer material and application thereof

A technology of hole transport layer and electron transport layer, which is applied in the field of solar cells, can solve the problems of toxicity, unfavorable environmental protection, unfavorable mass production, etc., and achieve the effect of low cost, uniform size, and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

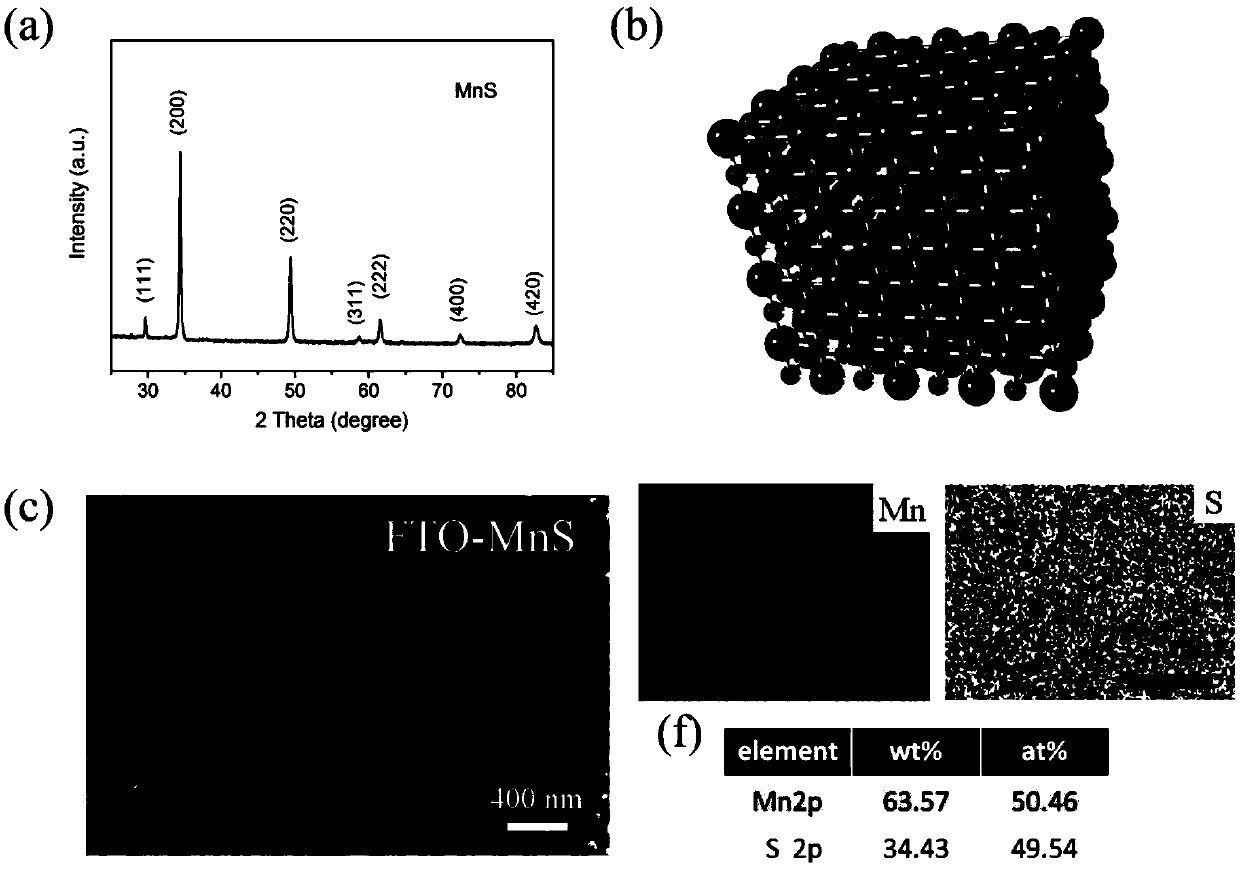

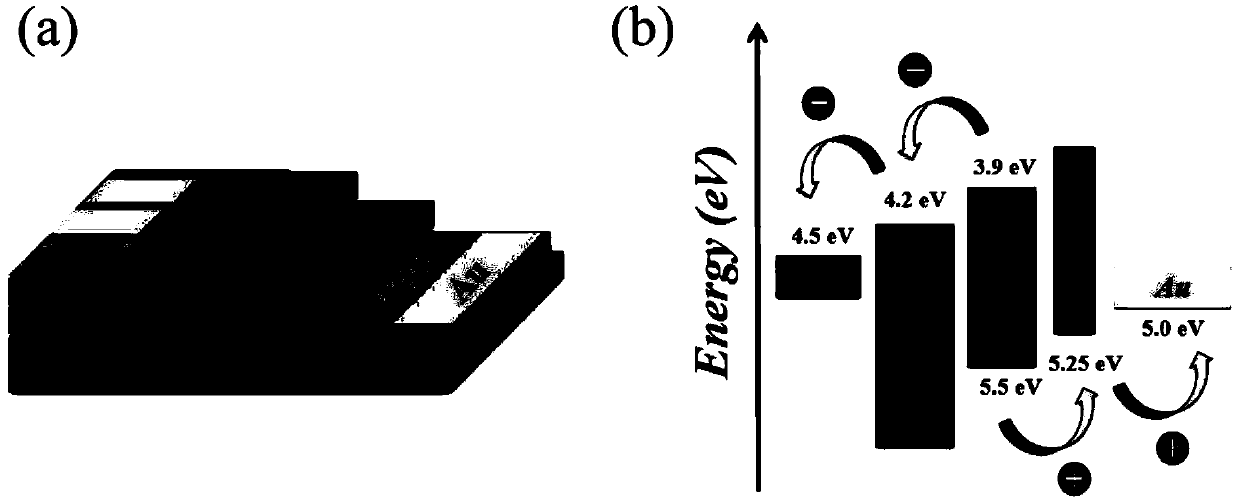

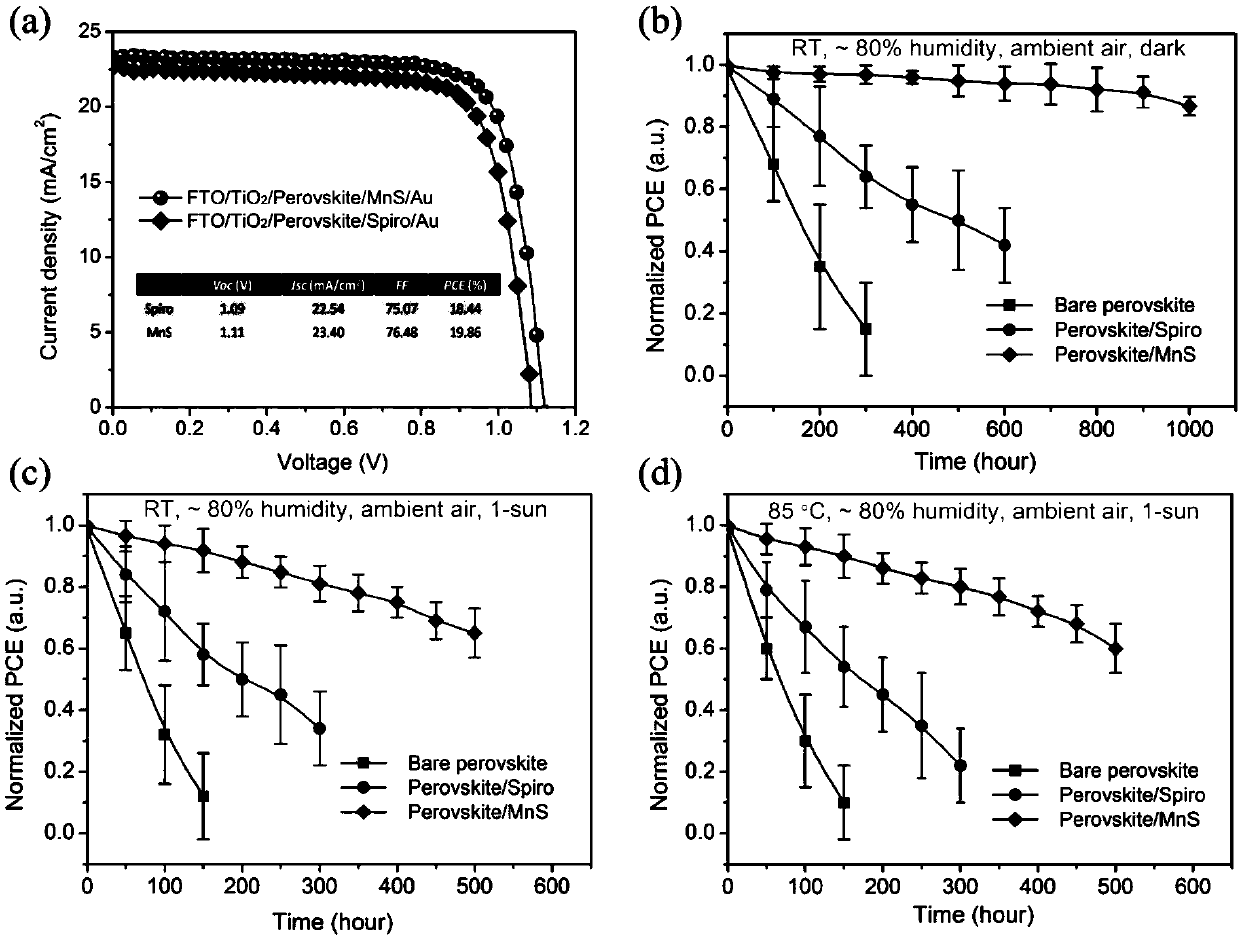

[0044] A kind of preparation method and application thereof of novel inorganic hole transport layer material MnS thin film among the present invention, comprise the following steps: (1) at first FTO substrate is cleaned, first carries out surface dirt to FTO substrate with cleaning liquid, subsequently will Put it into a mixed solution containing deionized water, absolute ethanol, and acetone with a volume ratio of 1:1:1, and perform ultrasonic cleaning for 30 minutes. This process is repeated three times, and then the FTO substrate is placed in a vacuum drying oven at 80°C. Bake for 120min, and finally treat with ultraviolet ozone for 15min; (2) Next, spin-coat on the FTO substrate with a 15mM isopropanol solution of bis(acetylacetonato)diisopropyl titanate, and the spin-coating parameter is 3500rpm , 25s, followed by annealing at 450°C for 30min to prepare dense TiO 2 ; (3) in the prepared dense TiO 2 On, spin-coated TiO 2 Slurry (18NR-T Dyesol), spin coating parameter is ...

Embodiment 2

[0046]A kind of preparation method and application thereof of novel inorganic hole transport layer material MnS thin film among the present invention, comprise the following steps: (1) at first FTO substrate is cleaned, first carries out surface dirt to FTO substrate with cleaning liquid, subsequently will Put it into a mixed solution containing deionized water, absolute ethanol, and acetone with a volume ratio of 1:1:1, and perform ultrasonic cleaning for 30 minutes. This process is repeated three times, and then the FTO substrate is placed in a vacuum drying oven at 80°C. Bake for 120min, and finally treat with ultraviolet ozone for 15min; (2) Next, use 10mM isopropanol solution of bis(acetylacetonato)diisopropyl titanate to spin-coat on the FTO substrate, and the spin-coating parameter is 5000rpm , 60s, followed by annealing at 400°C for 20min; (3) in the prepared dense TiO 2 On, spin-coated TiO 2 Slurry (18NR-T Dyesol), spin-coating parameter is 6000rpm, 20s, followed by ...

Embodiment 3

[0048] A kind of preparation method and application thereof of novel inorganic hole transport layer material MnS thin film among the present invention, comprise the following steps: (1) at first FTO substrate is cleaned, first carries out surface dirt to FTO substrate with cleaning liquid, subsequently will Put it into a mixed solution containing deionized water, absolute ethanol, and acetone with a volume ratio of 1:1:1, and perform ultrasonic cleaning for 30 minutes. This process is repeated three times, and then the FTO substrate is placed in a vacuum drying oven at 80°C. Bake for 120min, and finally treat with ultraviolet ozone for 15min; (2) Next, spin-coat on the FTO substrate with a 20mM isopropanol solution of bis(acetylacetonato)diisopropyl titanate, and the spin-coating parameter is 2000rpm , 20s, followed by annealing at 500°C for 60min; (3) in the prepared dense TiO 2 On, spin-coated TiO 2 Slurry (18NR-T Dyesol), spin-coating parameter is 3000rpm, 60s, followed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com