A kind of anti/heat insulation stealth integrated skin and preparation method thereof

A technology of skin and heat insulation layer, which is applied in the field of anti/heat insulation stealth integrated skin and its preparation, and can solve the problems of low-frequency stealth performance that cannot be applied to metamaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

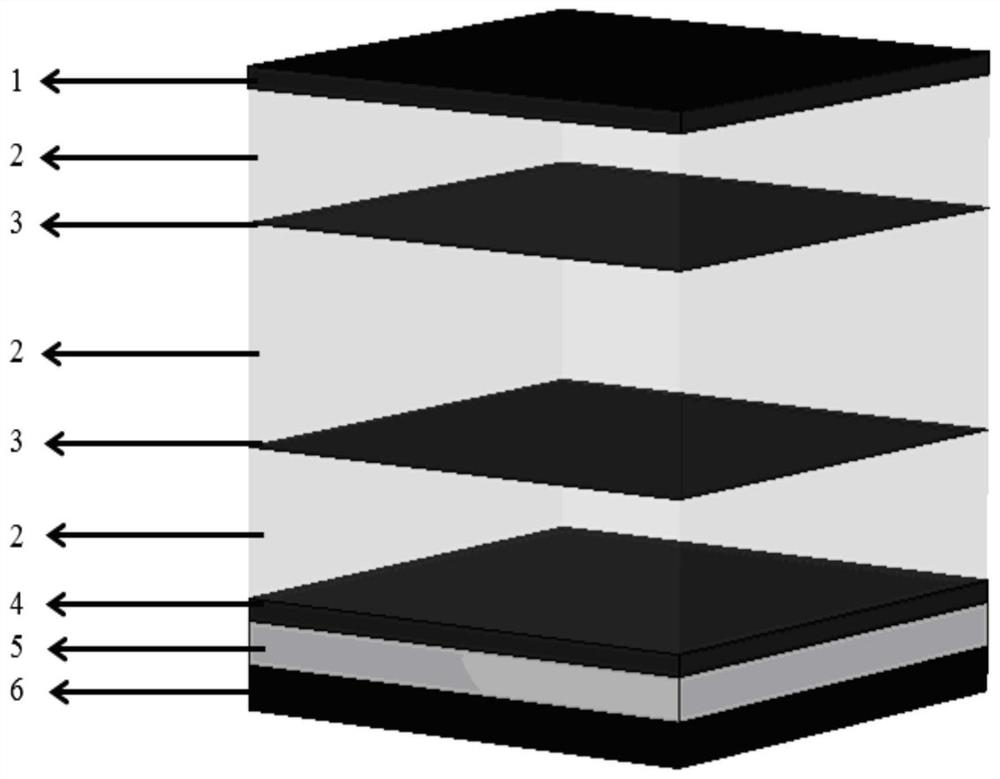

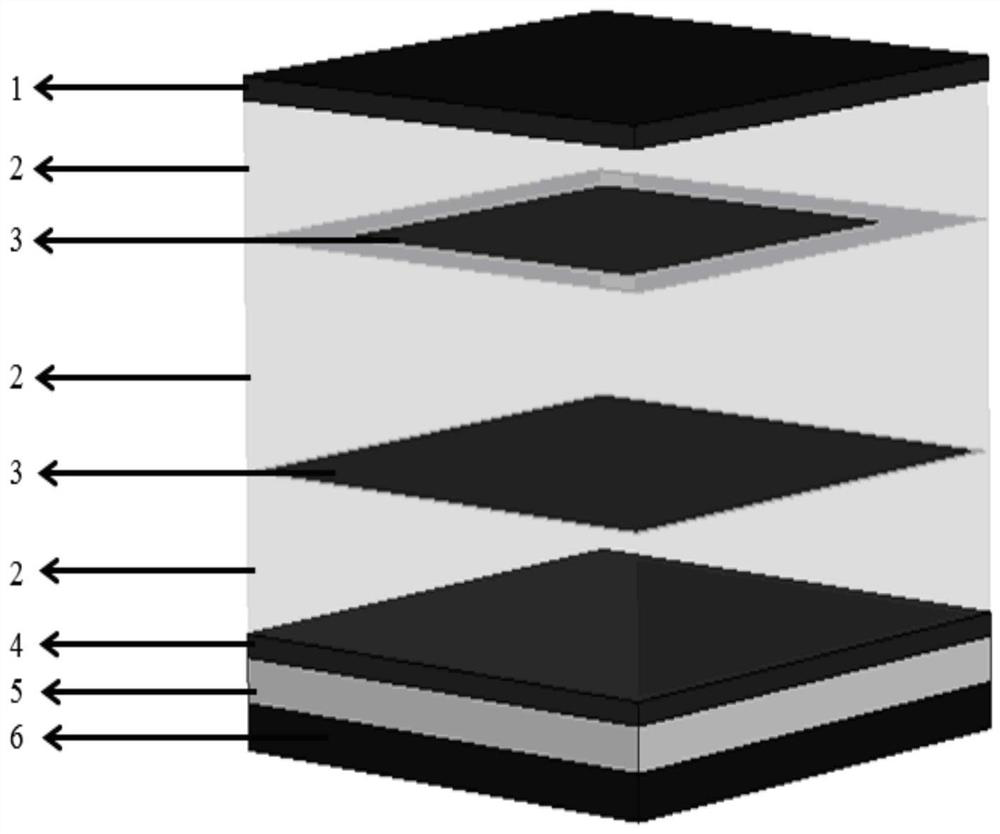

Method used

Image

Examples

Embodiment 1

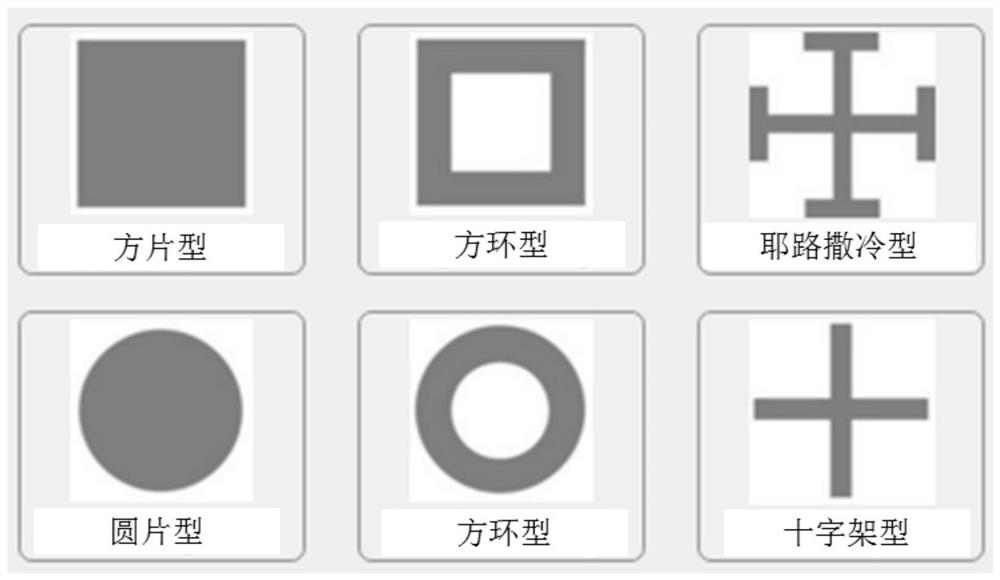

[0039] Step 1: Prepare the metal structure layer

[0040] Titanium alloy Ta5 is selected as the high-strength metal alloy as the structural layer, and a metal structural layer with a thickness of 3mm is obtained by machining, and prefabricated holes are prepared by machining technology, which is convenient for bolt connection in the later stage. The spacing of the prefabricated holes is 300mm, and the The hole diameter is about 6mm.

[0041] Step 2: Preparation of organic absorbing layer

[0042] Pour fluorine rubber and micron magnetic nickel powder (30wt.%) into the open mill and knead evenly, and the kneading temperature is 50°C, and the above-mentioned mixture is pressed into a wave-absorbing layer raw film with a thickness of 2mm by a calender, and cut into Put the designed shape into the mold, heat up and vulcanize after closing the mold, and obtain the required magnetic wave-absorbing patch material. The dielectric constant and dielectric loss are about 20 and 0.1, res...

Embodiment 2

[0052] Step 1: Prepare the metal structure layer

[0053] Nickel alloy C276 is selected as the high-strength metal alloy as the structural layer, and a metal structural layer with a thickness of 0.8mm is obtained by machining, and prefabricated holes are prepared by machining technology, which is convenient for bolt connection in the later stage. The hole diameter is about 16mm.

[0054] Step 2: Prepare resin matrix containing magnetic absorber

[0055] Using micron magnetic iron-nickel alloy powder (75wt.%) as the wave absorbing agent and polyimide as the solvent, the wave absorbing agent and the solvent are fully mixed by mechanical stirring and ultrasonic dispersion to form a wave absorbing matrix to prepare the bottom magnetic resin base composite absorbing layer.

[0056] The third step: preparation of organic absorbing layer

[0057] The magnetic resin-based composite material layer is made of silica fiber-reinforced polyimide-based composite material, and aluminum ox...

Embodiment 3

[0067] Step 1: Prepare the metal structure layer

[0068] Titanium alloy Ta5 is selected as the high-strength metal alloy as the structural layer, and a metal structural layer with a thickness of 4mm is obtained by machining, and prefabricated holes are prepared by machining technology, which is convenient for bolt connection in the later stage. The spacing of the prefabricated holes is 260mm, and the The hole diameter is about 4mm.

[0069] Step 2: Prepare resin matrix containing magnetic absorber

[0070] Using micron iron powder (60wt.%) as a wave absorbing agent and polytetrafluoroethylene as a solvent, the wave absorbing agent and solvent are fully mixed by mechanical stirring and ultrasonic dispersion to form a wave-absorbing matrix to prepare the bottom magnetic resin-based composite material Absorbing layer.

[0071] The third step: preparation of organic absorbing layer

[0072] The magnetic resin-based composite material layer is made of quartz fiber-reinforced PT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com