Carbon material loaded silver-platinum nano-alloy composite material and preparation method thereof

A technology of composite materials and carbon materials, which is applied in the field of silver-platinum nano-alloy composite materials supported by carbon materials and its preparation, can solve the problems of metal catalyst shedding, catalyst structure collapse, corrosion, etc., and achieve reduced production difficulty, high yield, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Configure mixed solution 1 with a mass ratio of ammonia water and methanol of 1:10, then mix silver carbonate and potassium hexachloroplatinate with mixed solution 1 at a mass ratio of 1:1:1 to make mixed solution 2, After standing at room temperature for 4 hours, the precursor solution was prepared.

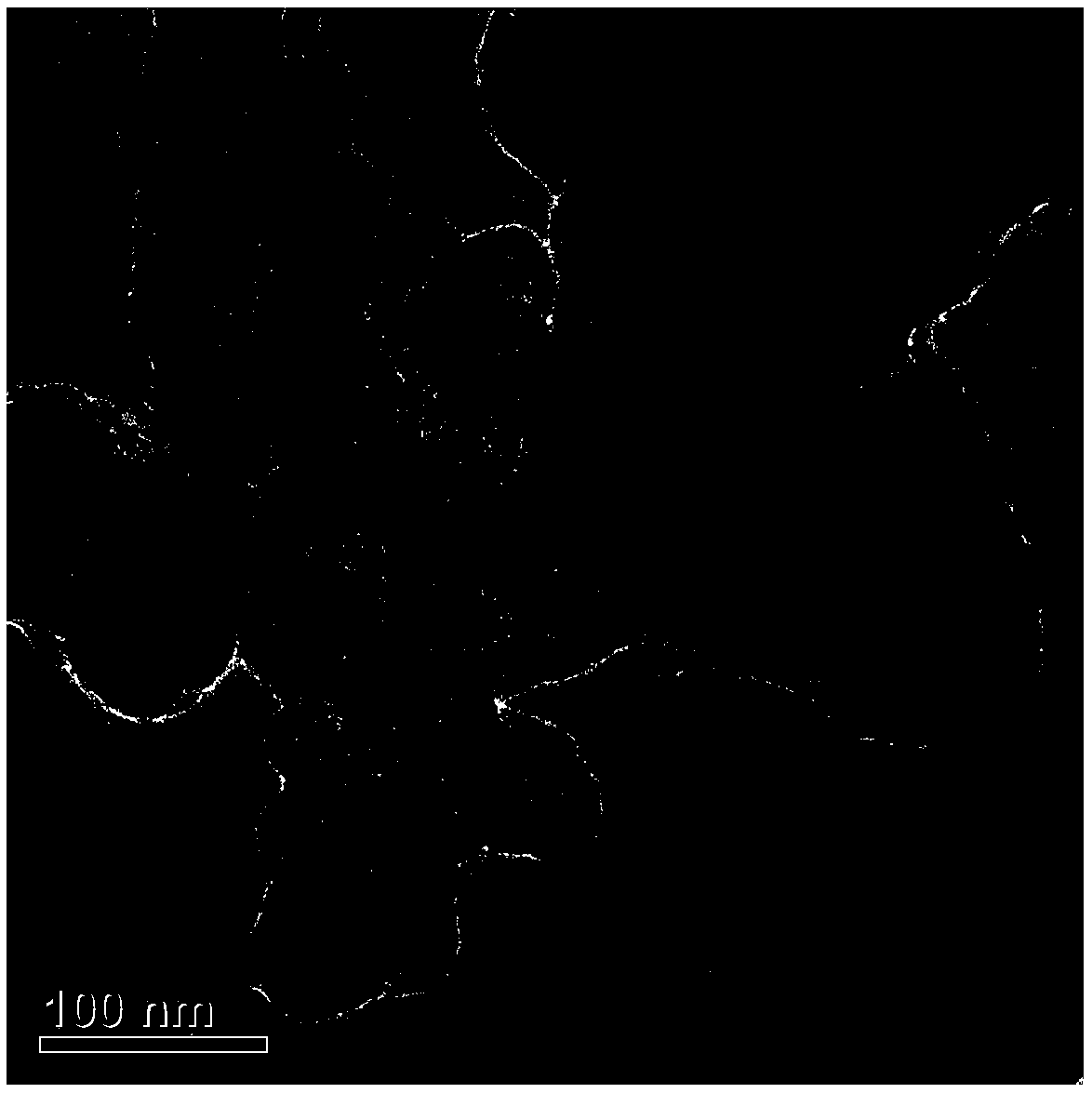

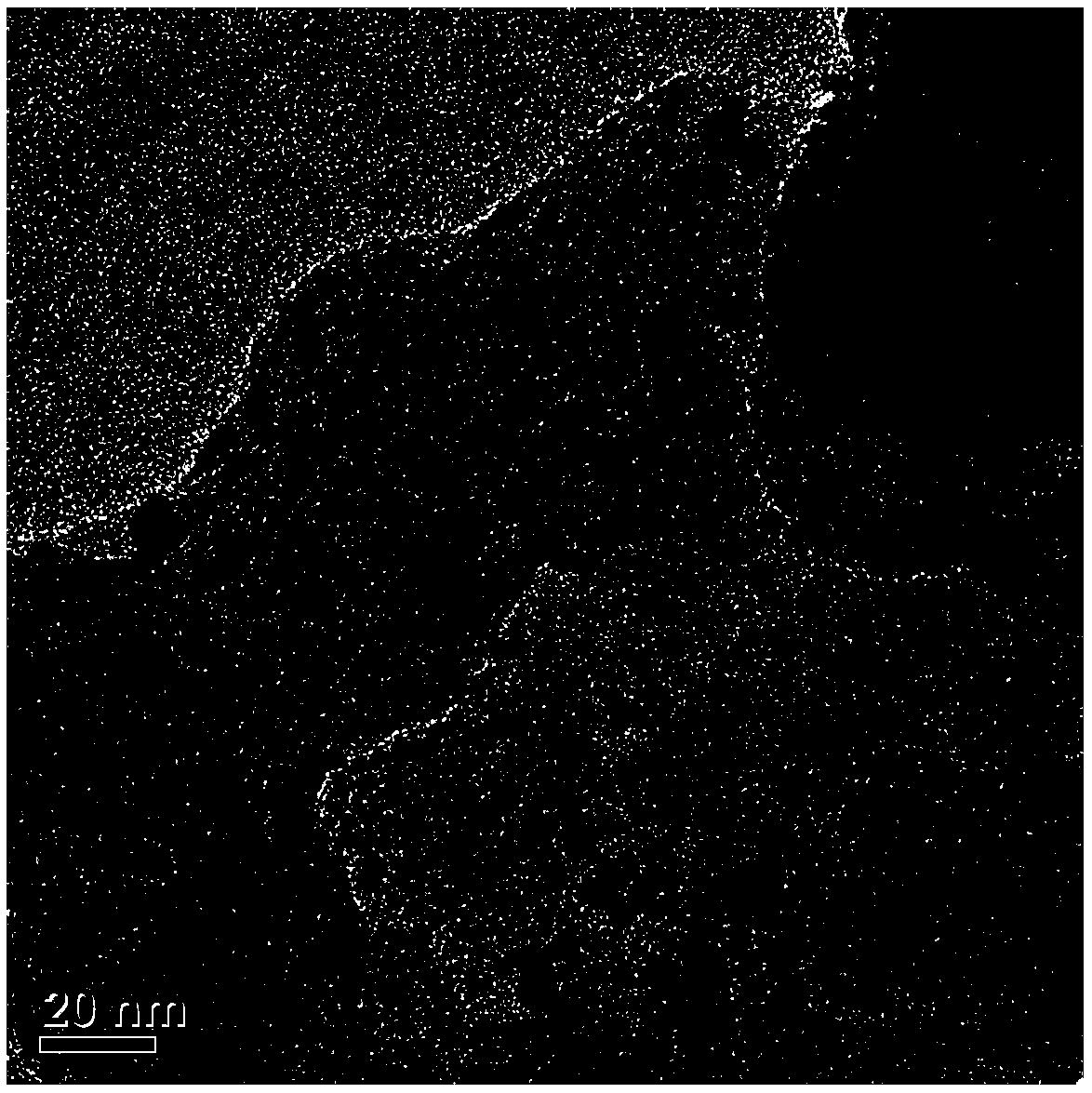

[0028] Mix the precursor solution, conductive carbon black and ethanol at a mass ratio of 1:1:1, heat the resulting mixture at 140°C for 2 hours, centrifuge and dry the resulting precipitate to prepare conductive carbon black-loaded silver platinum nanoparticles alloy composites. figure 1 with figure 2 The transmission electron microscope image of the silver-platinum nano-alloy composite material loaded with conductive carbon black shows that the composite material is composed of metal nanoparticles and carbon supports.

Embodiment 2

[0030] Prepare mixed solution 1 with a mass ratio of ammonia water and acetone of 1:5, then mix silver nitrate, chloroplatinic acid and mixed solution 1 with a mass ratio of 1:5:10 to make mixed solution 2, and then Stand still for 5 hours to prepare the precursor solution.

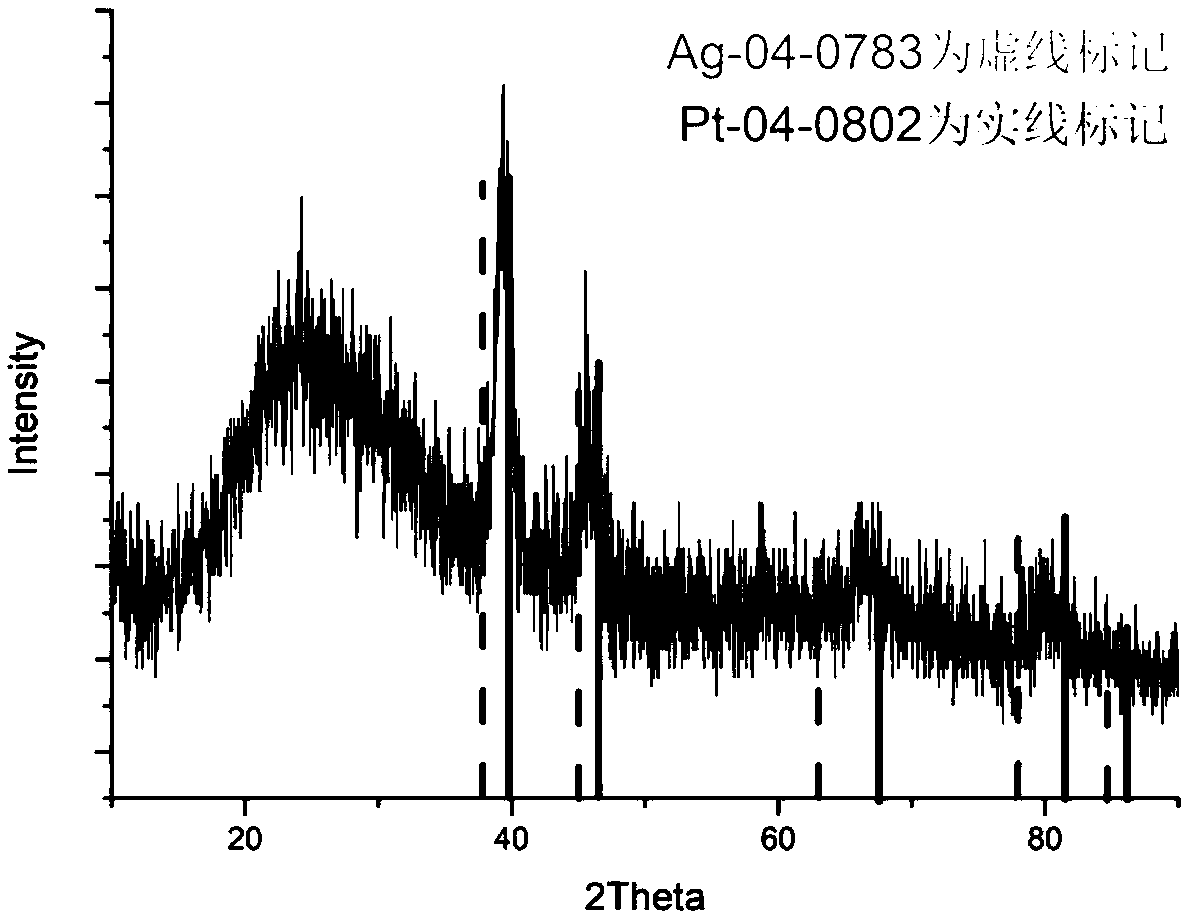

[0031] Mix the precursor solution, heteroatom-doped carbon material and ethylene glycol at a mass ratio of 1:100:100, heat the resulting mixture at 120°C for 4 hours, centrifuge and dry the resulting precipitate to obtain the heteroatom-doped Silver-platinum nanocomposites supported by heterocarbon materials. image 3 It is the XRD pattern of the silver-platinum nano-alloy composite material supported by heteroatom-doped carbon material, it can be seen that the position of the X-ray diffraction peak of the material is between the pure silver and pure platinum samples, which proves that it is composed of alloy structure composition.

Embodiment 3

[0033] Prepare mixed solution 1 with a mass ratio of ammonia water and ethyl acetate of 1:1, and then mix silver sulfate, potassium tetrachloroplatinate and mixed solution 1 at a mass ratio of 1:10:15 to make a mixed solution 2, and then stand at room temperature for 6 hours to prepare a precursor solution.

[0034] Mix the precursor solution, carbon nanotubes and acetonitrile at a mass ratio of 1:500:500, heat the resulting mixture at 80°C for 6 hours, centrifuge and dry the resulting precipitate to prepare carbon nanotube-loaded silver-platinum nanoalloys composite material. Figure 4 The transmission electron microscope image of the silver-platinum nano-alloy composite material supported by carbon nanotubes prepared in this example shows that the prepared composite material has a good crystal phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com