Method of preparing supported metal nickel-based catalyst

A nickel-based catalyst and supported technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc. Long period and other issues, to achieve the effect of high catalytic regeneration performance, high catalytic activity, good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

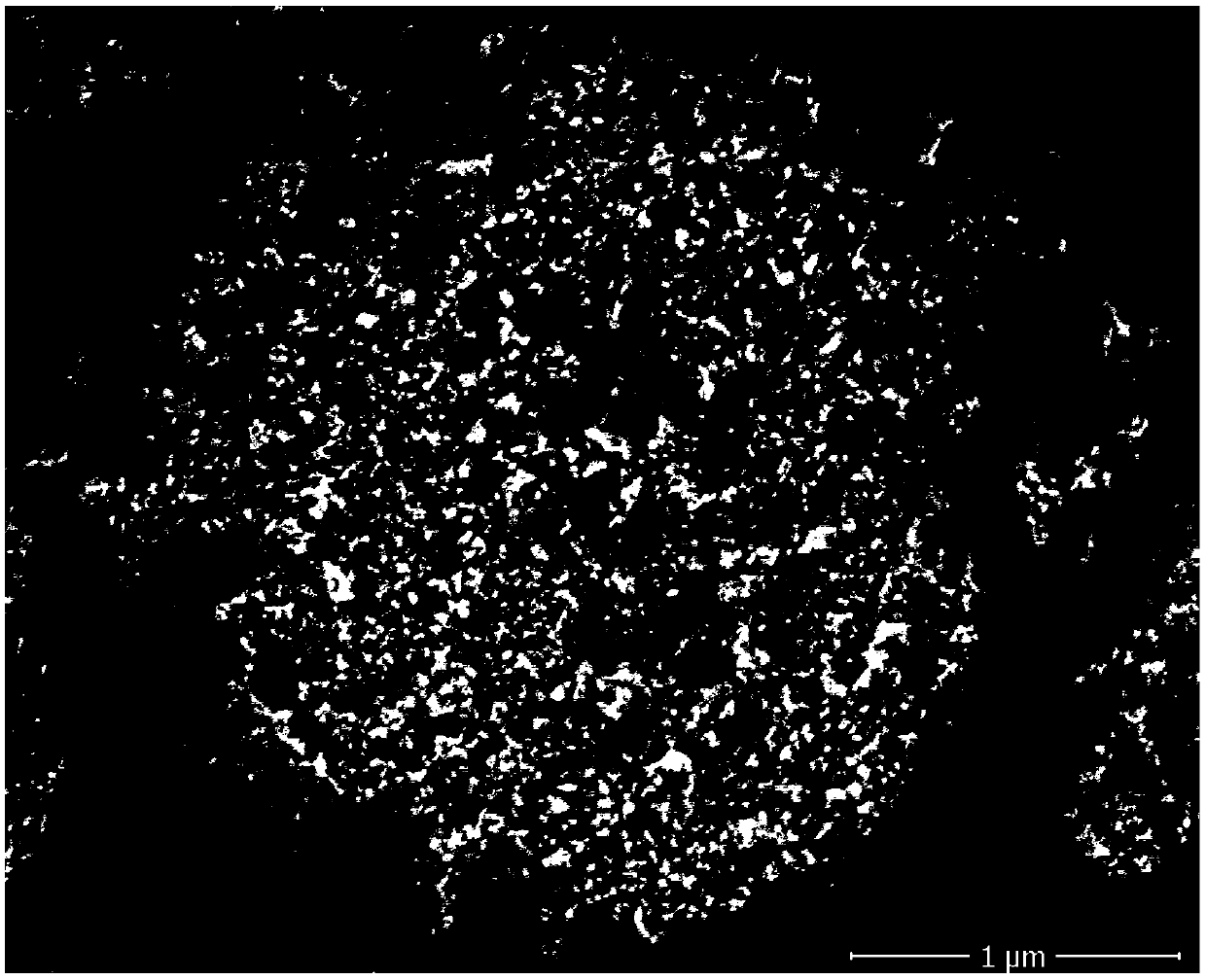

Image

Examples

Embodiment 1

[0038] The first step, the processing of tourmaline:

[0039] Measure tourmaline, deionized water and triethanolamine grinding aid in mass ratio as tourmaline: deionized water: triethanolamine grinding aid=1: 1: 0.01, under normal temperature and pressure, will measure Put tourmaline, deionized water and triethanolamine grinding aid together in a horizontal sand mill for 1 hour, keep the temperature range of the abrasive at 0-20°C, then wash the ground product with deionized water, and dry it at 60°C for 6 hours , roasting at 500°C for 3 hours, completing the treatment of tourmaline, and producing powdered tourmaline for subsequent use;

[0040] The second step, the preparation of reactant raw material mixture:

[0041] The nickel nitrate, aluminum nitrate and zinc nitrate that take required amount are dissolved in deionized water, make the concentration of Ni ion be 0.1mol / L, the mol ratio of three kinds of metal ions is nickel ion: aluminum ion: zinc ion=9: 20:1, stirred a...

Embodiment 2

[0047] The first step, the processing of tourmaline:

[0048] Measure tourmaline, deionized water and triisopropanolamine grinding aid=1: 1.5: 0.03 by mass ratio for tourmaline: deionized water: triisopropanolamine grinding aid, at normal temperature Press down, put the measured tourmaline, deionized water and triisopropanolamine grinding aid together in a disc sand mill and grind for 2 hours, keep the temperature of the abrasive in the range of 0-20°C, and then use the ground product Wash with ionized water, dry at 70°C for 9 hours, roast at 650°C for 4 hours, complete the treatment of tourmaline, and obtain powdered tourmaline for future use;

[0049] The second step, the preparation of reactant raw material mixture:

[0050] Nickel acetate, aluminum acetate and zinc acetate that take required amount are dissolved in deionized water, make the concentration of Ni ion be 0.3mol / L, the mol ratio of three kinds of metal ions is nickel ion: aluminum ion: zinc ion=8: 20:2, stirr...

Embodiment 3

[0056] The first step, the processing of tourmaline:

[0057] Tourmaline by mass ratio: deionized water: ethylene glycol grinding aid=1: 2: 0.05 measures required amount of tourmaline, deionized water and ethylene glycol grinding aid, under normal temperature and pressure, Measured tourmaline, deionized water and ethylene glycol grinding aid were placed together in a basket sand mill for grinding for 3 hours, keeping the abrasive temperature range from 0 to 20°C, and then the ground product was washed with deionized water, and ground at 80 Drying at ℃ for 12 hours, roasting at 800 ℃ for 5 hours, completing the treatment of tourmaline, and making powdered tourmaline for future use;

[0058] The second step, the preparation of reactant raw material mixture:

[0059] The nickel chloride, aluminum chloride and zinc chloride that take required amount are dissolved in deionized water, make the concentration of Ni ion be 0.5mol / L, the mol ratio of three kinds of metal ions is nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com