A kind of hydrogen peroxide synthesis device and method

A technology for hydrogen peroxide, synthesis device, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, organic compound/hydride/coordination complex catalyst, etc. It can solve the problems of slow reaction rate, high risk factor and low selectivity of hydrogen peroxide, so as to reduce the entrainment loss, improve the reaction efficiency and increase the catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

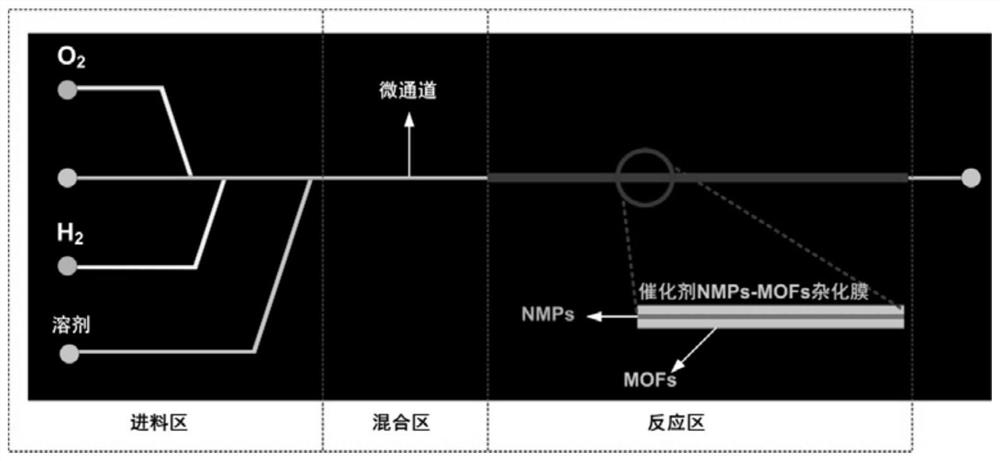

[0059] Another embodiment of the present invention discloses a method for preparing a sandwich-structured NMPs-MOFs hybrid membrane: comprising the following steps:

[0060] Step 1: Prepare a precursor solution and a metal salt solution for preparing a metal organic framework, and mix the two in equal amounts to obtain a mixed solution;

[0061] Step 2: Pass the mixed solution for preparing the metal-organic framework into the microchannel of the hydrogen peroxide synthesis device, make it self-grow on the inner wall of the microchannel at a suitable temperature, and dry to obtain the bottom metal-organic framework membrane;

[0062] Step 3: preparing a metal salt solution for preparing metal nanoparticles;

[0063] Step 4: Prepare metal nanoparticles by liquid phase reduction method and coat them on the metal-organic framework membrane at the bottom of the reaction zone;

[0064] Step 5: Continue to pass the mixed solution for preparing the metal-organic framework into the m...

Embodiment 1

[0079] The Pt-Ni / ZIF-8 hybrid film was prepared by the following method:

[0080] Step 1: Add Zn(NO 3 ) 2 (12mmol) and 2-methylimidazole (25mmol) are dissolved in methanol (250mL) to prepare ZIF-8 precursor solution;

[0081] Step 2: Zn(NO 3 ) 2 (12mmol) was dissolved in deionized water (250mL) to prepare zinc nitrate aqueous solution;

[0082] Step 3: Take an equal amount of ZIF-8 precursor solution and zinc nitrate aqueous solution and mix thoroughly. At room temperature, pass the mixed solution into the microchannel formed by the fastening of the substrate and cover sheet. The time for passing the mixed solution is 80 minutes , and then washed with methanol and dried with nitrogen to obtain the bottom ZIF-8 film;

[0083] Step 4: H 2 PtCl 6 and Ni(NO 3 ) 2 As a precursor, Pt was prepared by liquid phase reduction method 1 Ni 3 metal nanoparticles, and Pt by spin-coating 1 Ni 3 Metal nanoparticles coated on the nascent ZIF-8 film;

[0084] Step 5: continue to p...

Embodiment 2

[0086] Synthesis of hydrogen peroxide by hydrogen-oxygen direct method: The microchannel reactor substrate and cover slip coated with Pt-Ni / ZIF-8 hybrid membrane were assembled by thermal bonding method; the liquid inlet was kept at a flow rate of 0.1mL / h Add methanol solvent, feed high-purity hydrogen into the hydrogen inlet at 50mL / h, and feed high-purity oxygen into the oxygen inlet at 50mL / h. The gas and liquid pass through the mixing zone and then flow through the catalytic bed area for reaction. The reaction temperature is 40°C. The reaction pressure was 0.1 MPa, and after 5 hours of stable reaction, the yield of hydrogen peroxide was 89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com