Room-temperature curing high-temperature-resistant organic silicon rubber material as well as preparation method and application of room-temperature curing high-temperature-resistant organic silicon rubber material

A silicone rubber, room temperature curing technology, used in adhesives, fire-retardant coatings, polymer adhesive additives, etc., can solve the problems of high cost and poor temperature resistance, reduce production costs, simplify the preparation process, and improve preparation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of above-mentioned polysilazane, described method comprises the steps:

[0048] (1) Drying the solvent, ammonia gas, difunctional chlorosilane and trifunctional chlorosilane, and drying the reaction device;

[0049] (2) Add the dried solvent into the reaction device through a metering pump, add the dried difunctional chlorosilane and trifunctional chlorosilane into the reaction device through a metering pump respectively, and pass the dried ammonia through a mass flow meter. Enter under the liquid level of reaction device, carry out ammonolysis reaction;

[0050] (3) Put the "slurry" system containing a large amount of ammonium chloride after the reaction into the filter device through the mortar pump, filter and wash the filter residue with a solvent, and collect the filtrate;

[0051] (4) The filtrate containing the polysilazane product is introduced into a thin-film evaporator with continuous distillation function through a material transfer p...

preparation example 1

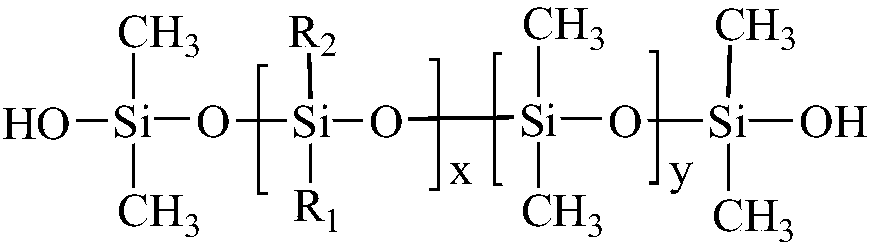

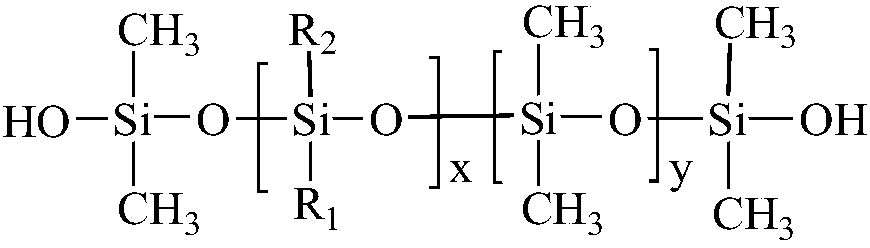

[0062] The preparation method of the hydroxy-terminated polysiloxane containing methyl phenyl group: take octamethylcyclotetrasiloxane and octaphenylcyclotetrasiloxane as raw materials, and the ratio of feed is calculated according to the required phenyl content. Tetramethylammonium hydroxide is used as an initiator, and acetic acid is used as an end-capping agent.

preparation example 2

[0064] The preparation method of hydroxyl-terminated polysiloxane containing methyl vinyl group: take octamethylcyclotetrasiloxane and octavinylcyclotetrasiloxane as raw materials, and calculate the feeding ratio according to the required vinyl content. Tetramethylammonium hydroxide is used as an initiator, and acetic acid is used as an end-capping agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com