A kind of method of fermentative production L-isoleucine

A technology of isoleucine and fermentation culture, which is applied in the field of fermentation and production of L-isoleucine, can solve the problems such as the need to improve the purity and acid production rate, low L-isoleucine yield, large environmental pollution and the like, and achieves the The effect of low cost, improved purity, and reduced ammonium nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

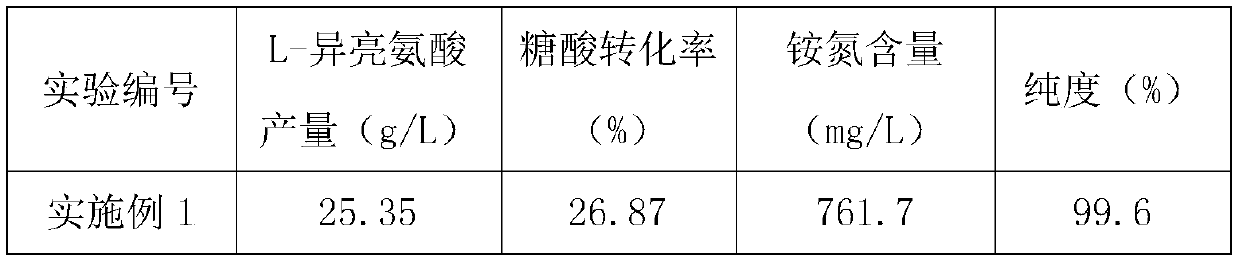

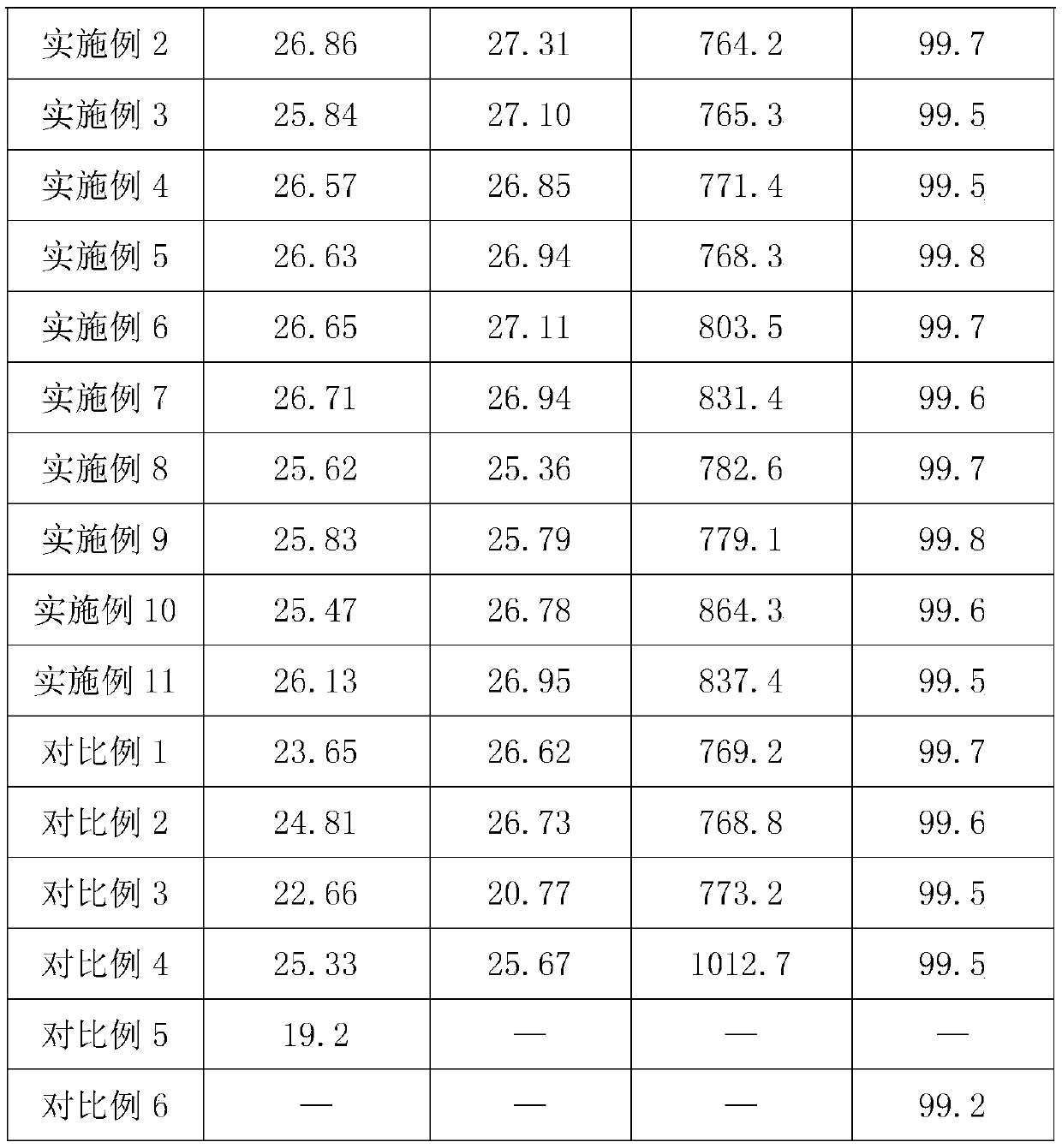

Examples

Embodiment 1

[0035] Example 1: A method for fermentative production of L-isoleucine

[0036] (1) Activation culture: Inoculate Corynebacterium blunt-toothed on the plate medium, activate and culture in the incubator for 12 hours at 30°C to obtain activated bacteria;

[0037] Plate medium: glucose 1g / L, peptone 10g / L, beef extract 10g / L, yeast extract 5g / L, NaCl 2.5g / L, agar powder 20g / L, pH=6.8-7.0;

[0038] (2) Seed culture: Take a ring of well-grown activated bacteria and inoculate it into a shake flask containing a seed medium for culture. The liquid volume is 200mL / 500mL. The conditions for seed culture are 30°C, 200r / min shaker culture 24h, obtain seed liquor;

[0039] Seed medium: glucose 92g / L, soybean meal hydrolyzate 83g / L, ammonium sulfate 18g / L, magnesium sulfate 3.5g / L, potassium dihydrogen phosphate 3.2g / L, pH=6.8-7.0;

[0040] (3) Fermentation culture: according to the inoculum size of 6%, get the seed liquid that step (2) obtains, inoculate in the 10L fermentor that contains...

Embodiment 2

[0044] Example 2: A method for fermentative production of L-isoleucine

[0045] The only difference from Example 1 is that the inoculum size of the fermentation culture in step (3) is 9%.

Embodiment 3

[0046] Example 3: A method for fermentative production of L-isoleucine

[0047] The only difference from Example 1 is that the inoculum size of the fermentation culture in step (3) is 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com