One-dimensional porous carbon fiber containing sulfide nano particles as well as preparation method and application of one-dimensional porous carbon fiber

A technology of porous carbon fibers and nanoparticles, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problem of low capacity of carbon materials, achieve good conductivity, short ion transmission distance, and facilitate infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

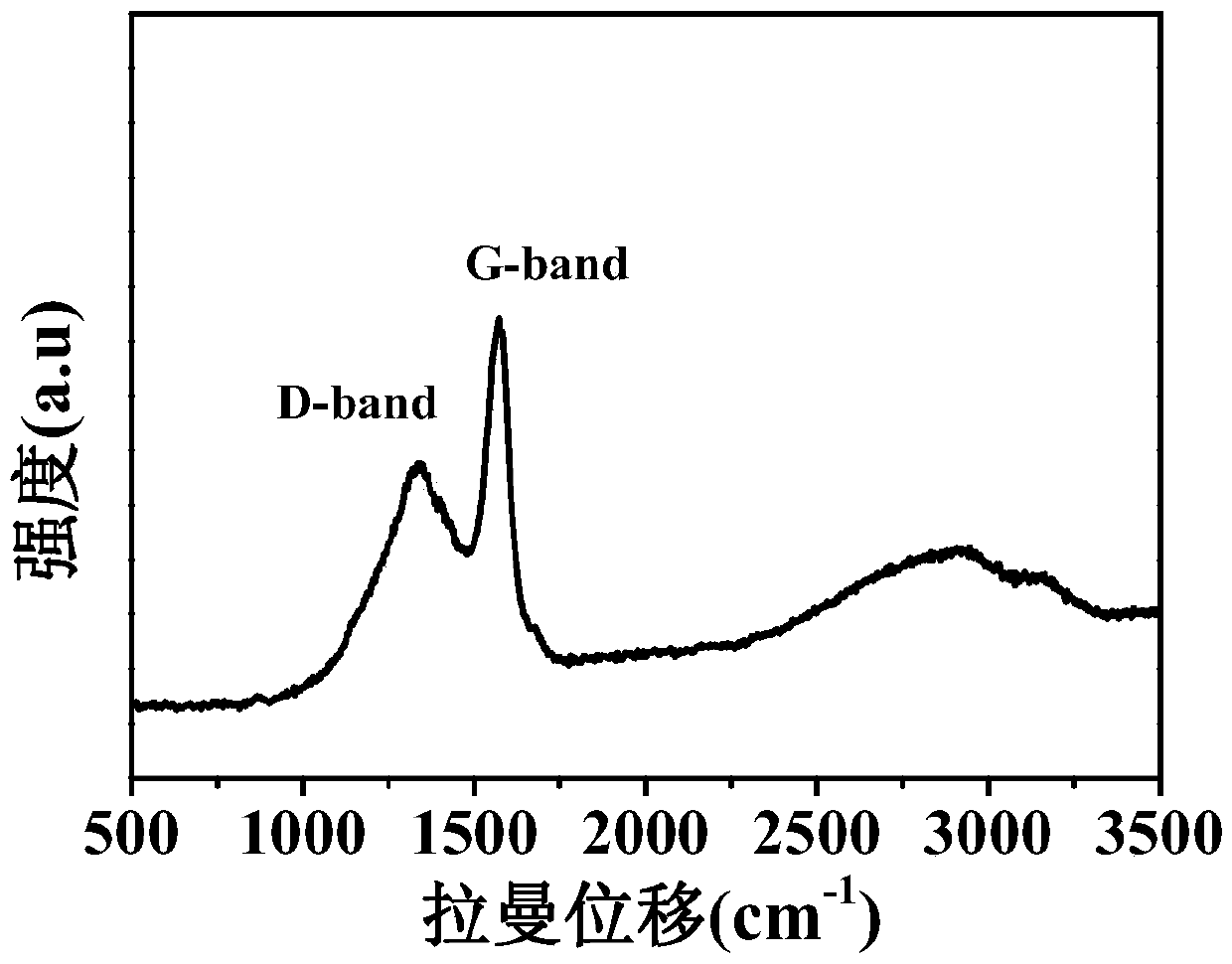

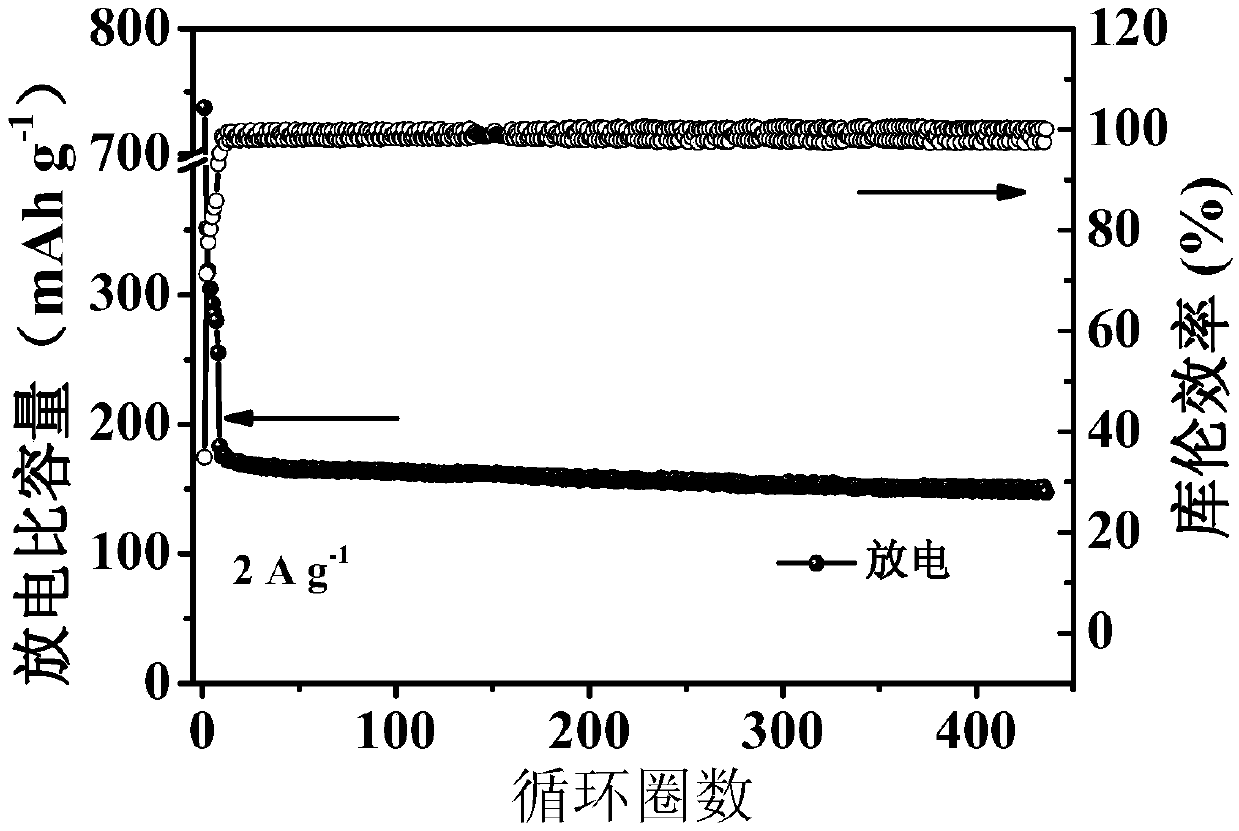

[0032] (1) Add 0.9 g of polyacrylonitrile, 0.1 g of polymethyl methacrylate, and 0.2 g of tin tetrachloride into 9 ml of chloroform, and ultrasonically stir in a water bath for 10 hours to obtain a fully dispersed spinning precursor slurry.

[0033] (2) After removing air bubbles from the slurry, electrospinning is performed at 15KV and a feed rate of 0.05ml / min to obtain a polymer nanofiber film.

[0034] (3) Pre-oxidize the polymer nanofilm at 250°C in an air atmosphere, heat up at a rate of 3°C / min, keep it warm for 2 hours, and then carbonize and vulcanize it under a 1wt.% hydrogen sulfide atmosphere (argon carrier). The temperature is 600°C, the heating rate is 4°C / min, and the holding time is 2 hours. One-dimensional porous carbon fibers containing sulfide nanoparticles were obtained after cooling.

[0035] (4) Get 0.2g of the one-dimensional porous carbon fiber containing sulfide nanoparticles prepared in this embodiment, 0.025g polyvinylidene fluoride (PVDF), 0.025 co...

Embodiment 2

[0037] (1) Add 0.9 g of polyvinyl alcohol, 0.1 g of polymethyl methacrylate, and 0.3 g of stannous chloride to 8 ml of chloroform, and ultrasonically stir in a water bath for 10 hours to obtain a fully dispersed spinning precursor slurry.

[0038] (2) After removing air bubbles from the slurry, electrospinning is performed at 15KV and a feed rate of 0.05ml / min to obtain a polymer nanofiber film.

[0039] (3) Pre-oxidize the polymer nanofilm at 250°C in air atmosphere, heat up at a rate of 3°C / min, keep it warm for 2 hours, and then carbonize and vulcanize it under a 10wt.% hydrogen sulfide atmosphere (argon carrier). The temperature is 600°C, the heating rate is 4°C / min, and the holding time is 2 hours. One-dimensional porous carbon fibers containing sulfide nanoparticles were obtained after cooling.

[0040] (4) Get 0.2g of the one-dimensional porous carbon fiber containing sulfide nanoparticles prepared in this embodiment, 0.025g polyvinylidene fluoride (PVDF), 0.025 conduc...

Embodiment 3

[0042] (1) Add 0.9g polylactic acid, 0.2g polymethyl methacrylate, and 0.4g antimony trichloride to 8 ml of N,N-dimethylformamide, and ultrasonically stir in a water bath for 10 hours to obtain fully dispersed Spin precursor slurry.

[0043] (2) After removing air bubbles from the slurry, electrospinning is performed at 15KV and a feed rate of 0.05ml / min to obtain a polymer nanofiber film.

[0044] (3) Pre-oxidize the polymer nanofilm at 250°C in an air atmosphere, heat up at a rate of 3°C / min, keep it warm for 2 hours, and then carbonize and vulcanize it under a 15wt.% hydrogen sulfide atmosphere (argon carrier). The temperature is 600°C, the heating rate is 4°C / min, and the holding time is 2 hours. One-dimensional porous carbon fibers containing sulfide nanoparticles were obtained after cooling.

[0045] (4) Get 0.2g of the one-dimensional porous carbon fiber containing sulfide nanoparticles prepared in this embodiment, 0.025g polyvinylidene fluoride (PVDF), 0.025 conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com