A closed reverse electrodialysis power generation method and device based on asymmetric ion exchange membrane

A reverse electrodialysis and ion exchange membrane technology, applied in the field of waste heat power generation, can solve the problems of large water consumption, limited application range, complex structure, etc., and achieve the effects of energy saving, high power generation efficiency, and small concentration polarization phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In a specific implementation process, the electrode is a carbon nanotube / lithium manganate composite electrode, which can be prepared by the following method:

[0048] First, the carbon nanotubes with a length of 30-100μm and an outer diameter of 10-20nm are ultrasonically dispersed in N-Methyl pyrrolidone, and then LiMn 2 O 4 Add to the CNT dispersion liquid, ultrasonic and suction filtration to obtain the carbon nanotube / lithium manganate composite material, the material and the binder polyvinylidene fluoride (Poly (vinylidene fluoride),) in the NMP after mixing and stirring, scrape coating on CNT / LMO electrode was obtained by vacuum drying on carbon-coated aluminum foil. This electrode can be used directly without the cathode and anode room. In the present invention, CNT is the abbreviation of carbon nanotube, NMP is the abbreviation of N-methyl-2-pyrrolidone, and PVDF is the abbreviation of polyvinylidene fluoride.

[0049] In a preferred implementation process, the ele...

Embodiment 1

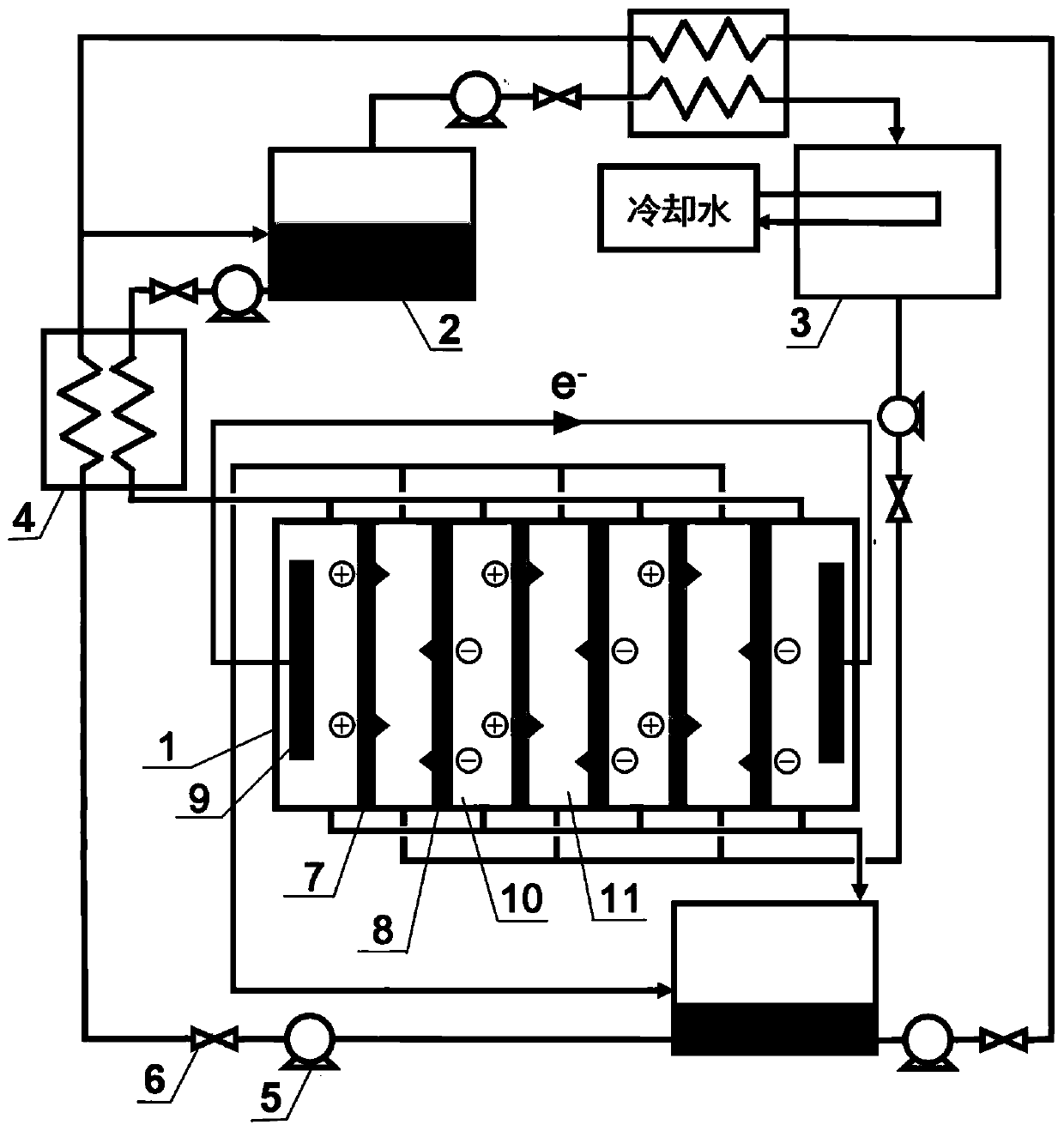

[0070] figure 1 It is a closed reverse electrodialysis power generation device used in the present invention, which is mainly composed of reverse electrodialysis module 1, gas-liquid separation generator 2, condenser 3, heat exchanger 4, peristaltic pump 5, valve 6, cation exchange Membrane 7, anion exchange membrane 8, electrode 9, concentrated solution tank 10, and weak solution tank 11.

[0071] The cation exchange membrane in the device is an asymmetric ion exchange membrane made of PES / SPEEK, with a thickness of 34μm, a large pore size of 125nm, and a small pore size of 11nm; the anion exchange membrane is an asymmetric ion exchange membrane made of PES / SPEEK / PDA. The thickness is 36μm, the large pore size is 125nm, and the small pore size is 7nm; the electrode is a sheet carbon nanotube / lithium manganate composite electrode with a thickness of 500μm; the working fluid is a lithium bromide solution, and the concentration of the concentrated lithium bromide solution is 0.5M. ...

Embodiment 2

[0078] The power generation device and the power generation process are exactly the same as in Example 1, except that the following parameters in the power generation device are changed:

[0079] The cation exchange membrane in the device is an asymmetric ion exchange membrane made of PES / SPEEK, with a thickness of 35μm, a large pore size of 250nm, and a small pore size of 15nm; the anion exchange membrane is an asymmetric ion exchange membrane made of PES / SPEEK / PDA. The thickness is 37.5μm, the large pore size is 250nm, and the small pore size is 12nm; the electrode is a 550μm flake carbon nanotube / lithium manganate composite electrode; the working fluid is a lithium bromide solution, and the concentration of the concentrated lithium bromide solution is 0.5M. The concentration of the dilute lithium bromide solution is 0.01M.

[0080] The results show that when the external resistance is 1000Ω, the output power of the generator is 0.025W / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com