Tartary buckwheat enzyme and preparation method thereof

A technology of tartary buckwheat enzyme and buckwheat enzyme, which is applied in food ingredients as antioxidants, functions of food ingredients, food science, etc., can solve problems such as no reports on the development and utilization of tartary buckwheat enzyme products, and achieve the effect of promoting the effect of hangover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of tartary buckwheat ferment, carried out according to the following steps:

[0035] (1) Get 10kg of tartary buckwheat, grind it, mix it with 20kg of brown sugar, add 300L of sterile water, and stir evenly;

[0036] (2) Inoculate Bacillus subtilis, lactic acid bacteria and saccharomyces, stir evenly, and ferment for 4 days at 32°C; the amount of inoculating Bacillus subtilis preparation is 100g, and the content of Bacillus subtilis live bacteria in the Bacillus subtilis preparation is 2×10 8 cfu / g; the amount of inoculated lactic acid bacteria preparation is 100g, and the content of live lactic acid bacteria in the lactic acid bacteria preparation is 1X10 8 cfu / g; the amount of inoculated yeast preparation is 100g, and the content of live yeast in the yeast preparation is 1X10 8 cfu / g;

[0037] (3) Send the fermented material into the ultrasonic tank, and the ultrasonic intensity is 0.15w / cm 3 Ultrasound for 90 minutes under the condition; then f...

Embodiment 2

[0040] A preparation method of tartary buckwheat ferment, carried out according to the following steps:

[0041] (1) Get 10kg of tartary buckwheat, 3kg of dry root product of symphysis, grind, mix with 20kg brown sugar, add sterile water 300L, stir;

[0042] (2) Inoculate Bacillus subtilis, lactic acid bacteria and saccharomyces, stir evenly, and ferment for 4 days at 32°C; the amount of inoculating Bacillus subtilis preparation is 100g, and the content of Bacillus subtilis live bacteria in the Bacillus subtilis preparation is 2×10 8 cfu / g; the amount of inoculated lactic acid bacteria preparation is 100g, and the content of live lactic acid bacteria in the lactic acid bacteria preparation is 1X10 8 cfu / g; the amount of inoculated yeast preparation is 100g, and the content of live yeast in the yeast preparation is 1X10 8 cfu / g;

[0043] (3) Send the fermented material into the ultrasonic tank, and the ultrasonic intensity is 0.15w / cm 3 Ultrasound for 90 minutes under the co...

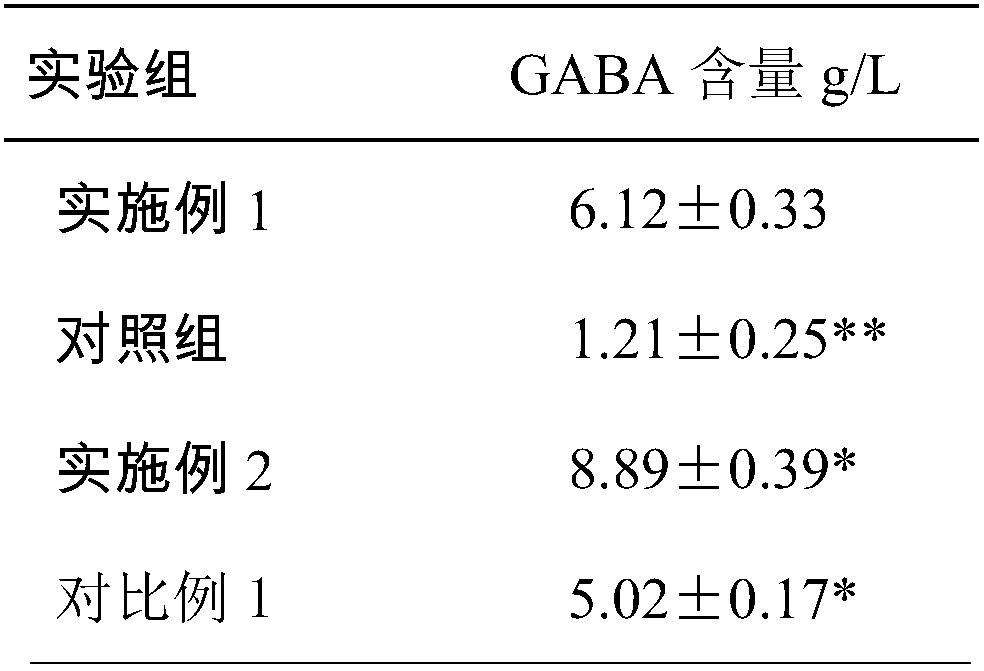

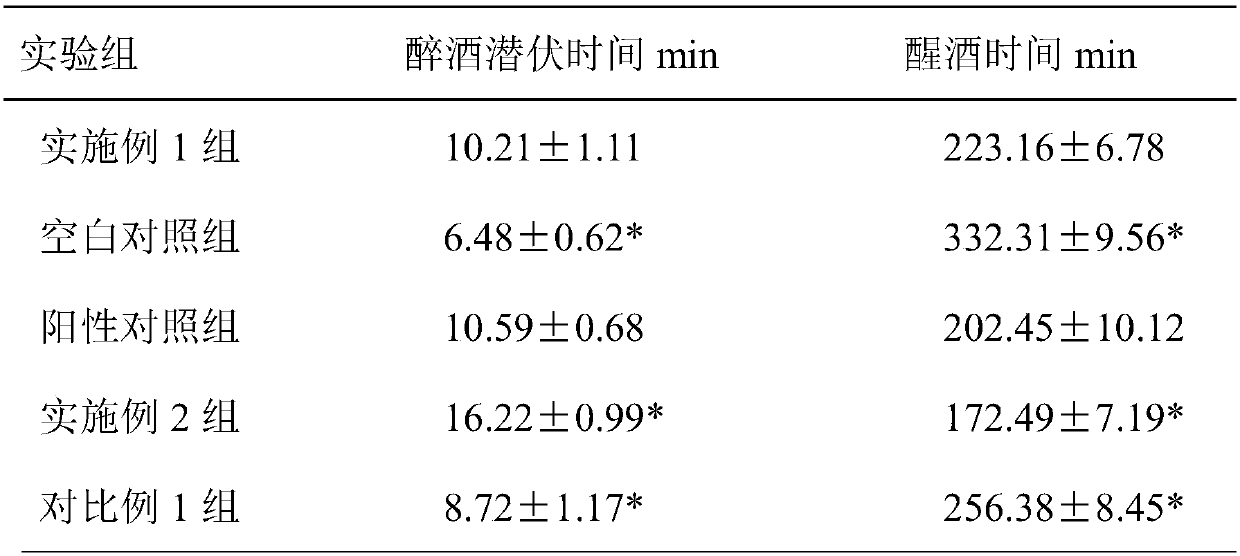

experiment example 1

[0050] Experimental example 1: Determination of GABA (γ-aminobutyric acid) in the sample

[0051] Using high performance liquid chromatography, the control experiment sample is the leachate after soaking tartary buckwheat flour for 10 hours; the test steps are as follows:

[0052] (1) Preparation of derivatization reagent: Accurately weigh 0.1g of OPA and 130 μL of β-mercaptoethanol and dissolve in 1mL of acetonitrile and 0.5mL of methanol, then add 0.5M boric acid solution and dilute to 20mL;

[0053] (2) The preparation of boric acid buffer solution: get boric acid 0.62g and KOH 0.52g and be dissolved in 20mL distilled water;

[0054] (3) Preparation of mobile phase A (sodium acetate buffer): take 8.0 g of anhydrous sodium acetate and dissolve it in 1000 mL of double distilled water, add 220 μL of triethylamine, adjust the pH to 7.2 with 5% glacial acetic acid, and then add 5 m L of tetrahydrofuran, mixed and passed through a 0.22um filter membrane;

[0055] (4) Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com