Preparation of multilayer cartilage complex containing cytokine microspheres through electrospinning 3D printing

A technology of 3D printing and cytokines, which is applied in prostheses, microcapsules, medical science, etc., can solve the problems that normal cartilage cannot provide friction resistance and support, and is easy to be damaged again, so as to facilitate repair, promote cell proliferation and differentiation, The effect of high structural precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

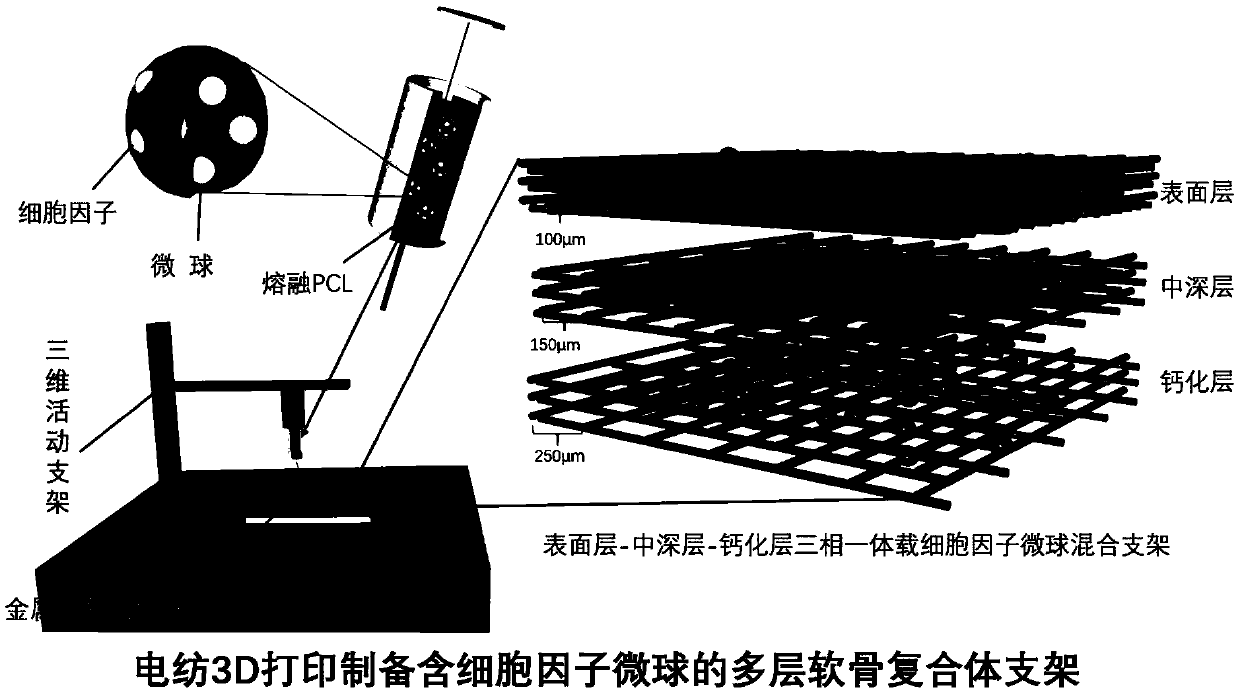

[0028] S2, the preparation of three-phase integrated support;

[0029] S3. Planting of cells: An appropriate amount of bone marrow mesenchymal stem cells is planted in each scaffold area.

[0030] Specifically, in the cultivation of the seed cells in the step S1, the bone marrow mesenchymal stem cells are cultured in a DMEM medium containing 10% fetal bovine serum in an incubator.

[0031] Specifically, the temperature of the incubator is 37° C., and there is 5% CO2 in the incubator.

[0032] Specifically, the preparation of the three-phase integrated stent in the step S2 includes the following steps:

[0033] S21. Model establishment: use 3D printing software to establish a printing model, which is in the shape of a multi-layer cylinder, and the gaps between the structural paths of each layer are adjusted and saved according to needs;

[0034] S22. Preparation of materials: Measure appropriate amounts of biopolymer materials A1, A2, and A3, and microspheres B1, B2, and B3. ...

Embodiment 1

[0041] (1) Use 3D printing software to build a printing model, which is multi-cylindrical, with different path gaps in the surface area, middle-deep area, and calcification layer area, and save it;

[0042] (2) Take an appropriate amount of polymer materials polycaprolactone and polydopamine microspheres, the polydopamine microspheres are respectively loaded with appropriate amount of TGFβ1, BMP7 and IGF cytokines and HA (hydroxyapatite) particles, and an appropriate amount of polyethylene glycol Alcohol, mixed with water to prepare a dispersion liquid, and the microspheres loaded with cytokines are uniformly dispersed in the dispersion liquid;

[0043](3) Equipment preparation: adjust the process parameters of the electrospinning 3D printing equipment: the diameter of the printing wire is 10-50 μm, the printing temperature is 65°C, the air pressure of the barrel is 600-1000KPa during the printing process, and the voltage of the negative high voltage module is - 2.5~-50kV, the...

Embodiment 2

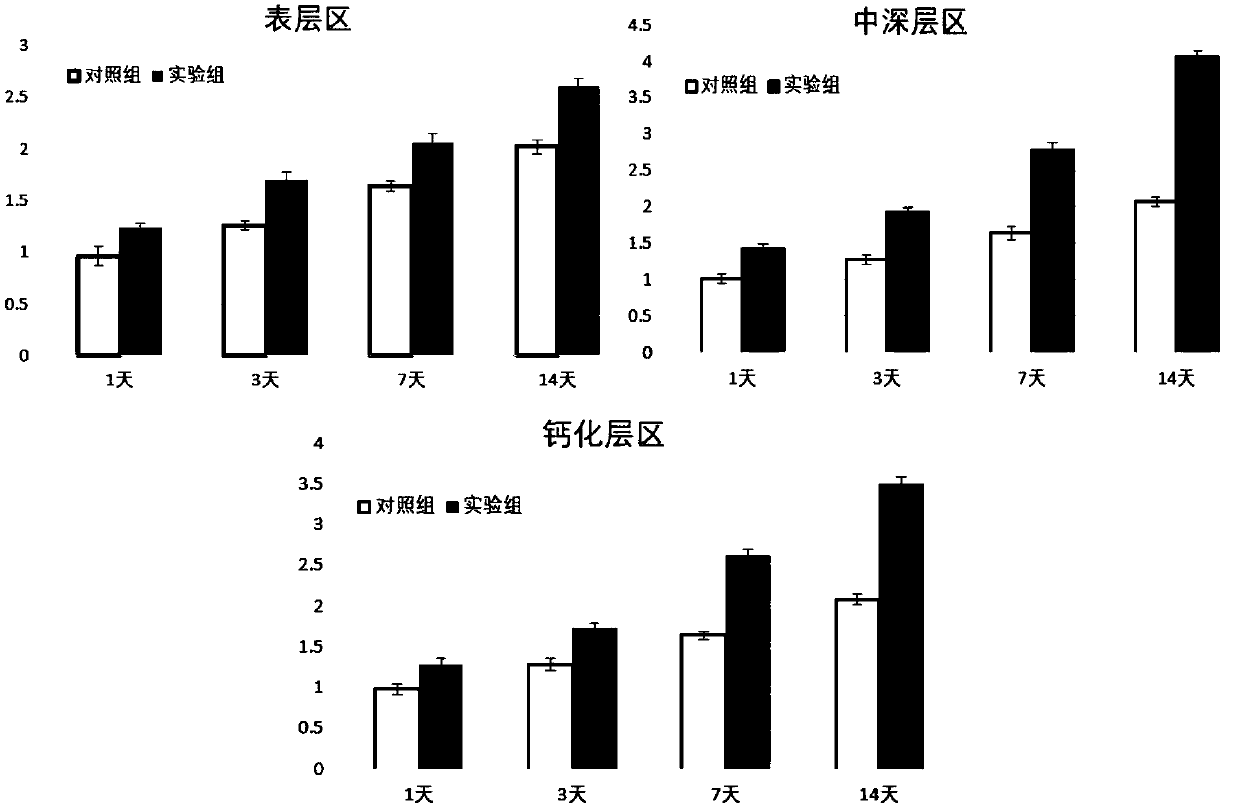

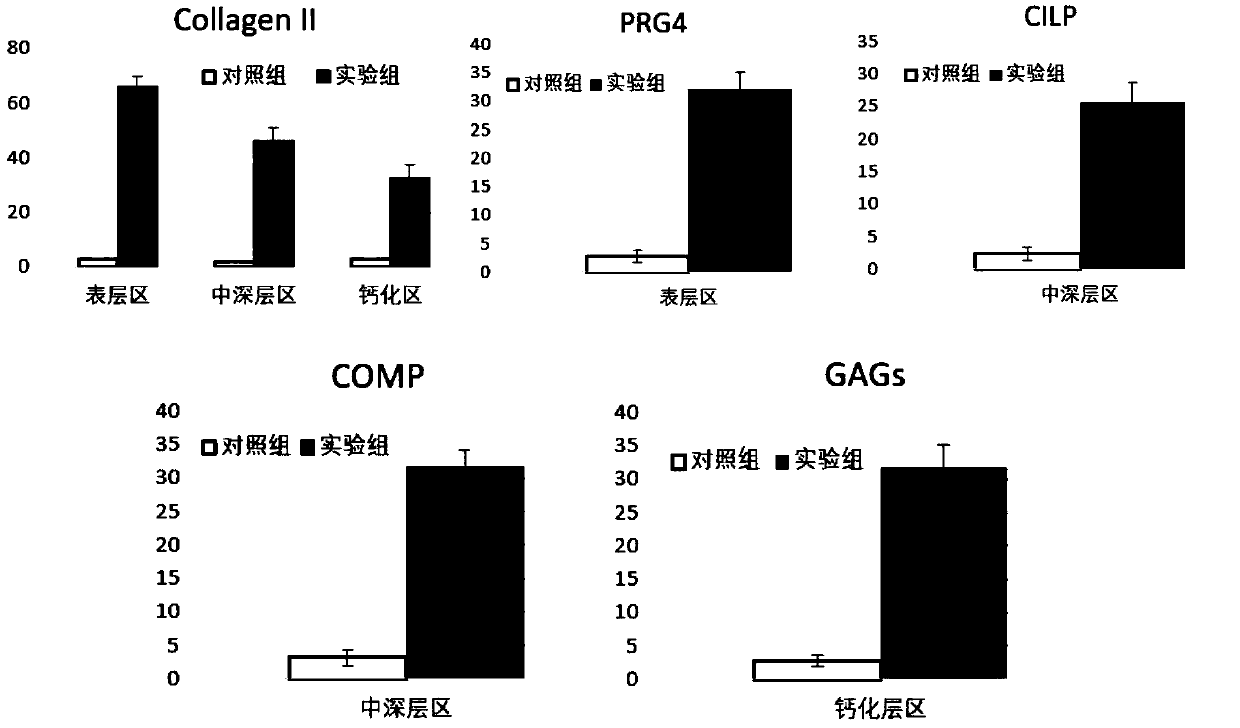

[0045] The cartilage layered scaffold obtained in the above-mentioned Example 1 was characterized for biocompatibility, and the three-phase integrated scaffold mixed with cytokine-loaded microspheres obtained in step (3) was planted with bone marrow stem cells and cultured in an incubator. The scaffolds obtained by three-dimensional printing of caprolactone were planted with bone marrow stem cells as the control group, and compared with each area of the three-phase scaffolds. After 1, 3, 5, and 7 days of culture, the cell viability in the surface area scaffolds was detected by MTT method. The results are shown in Fig. As shown in 2, it shows that the cells on the scaffold obtained by the electrospinning 3D printing technology with cytokine microspheres have good proliferation behavior, the cell viability is better, and the proliferation behavior is more significant than that of the control group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com