Soil heavy metal ion adsorbing and separating material and preparation method thereof

A heavy metal collector and composite material technology, applied in the application field of inorganic mineral materials, can solve problems such as adsorption, and achieve the effects of expanding specific surface area, wide absorption, and increasing binding capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

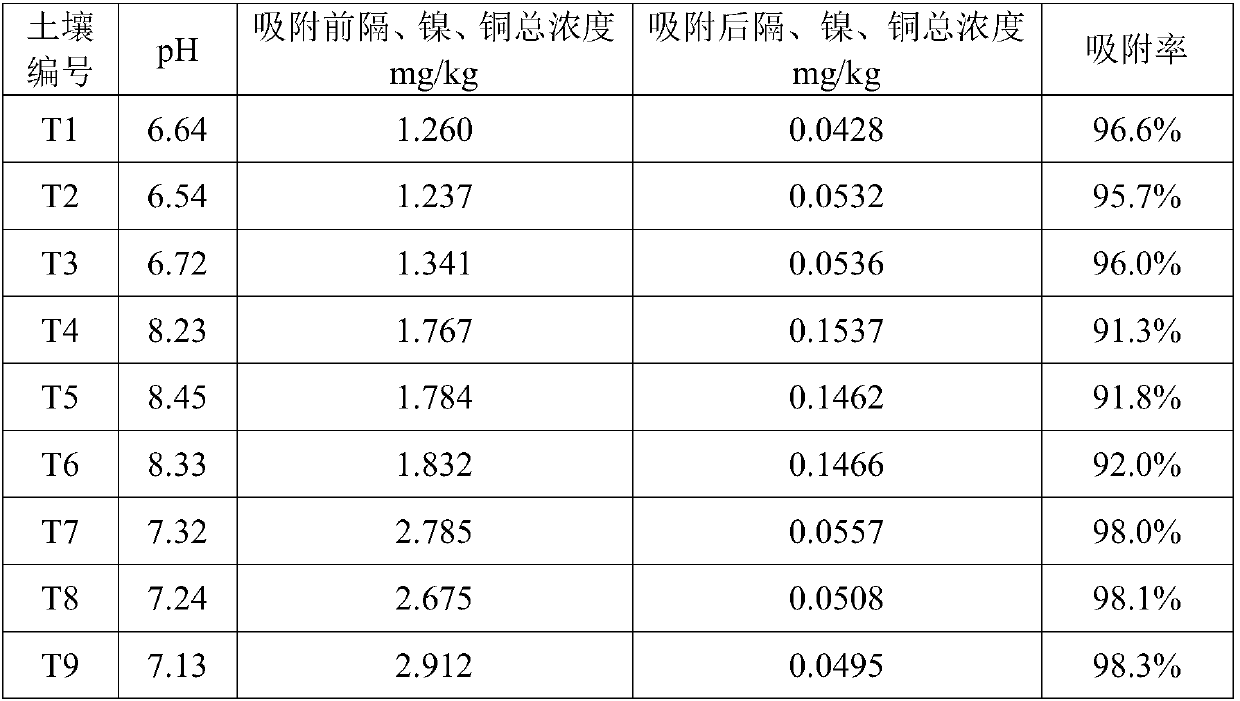

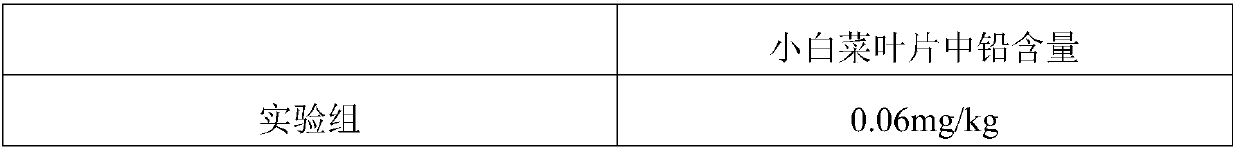

Examples

Embodiment 1

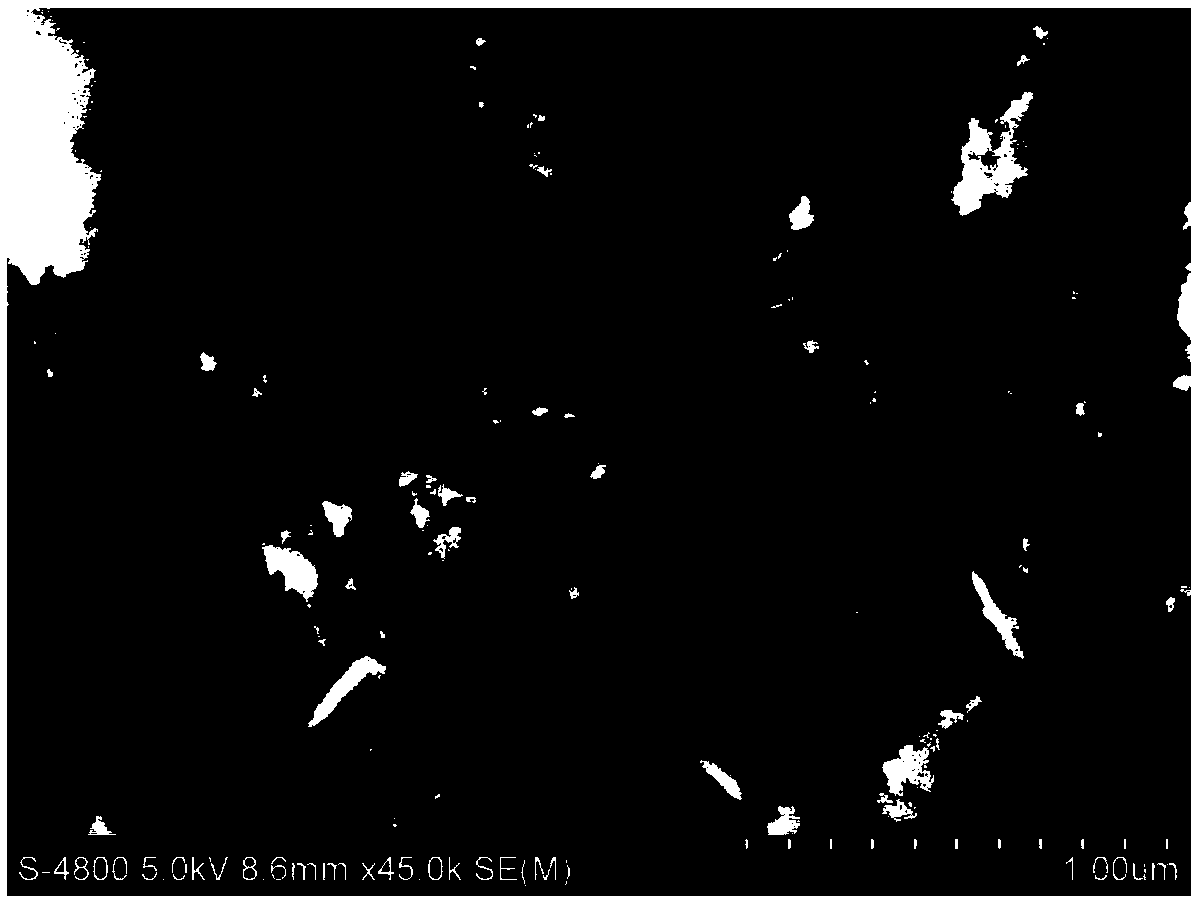

[0038] 1. Purification of attapulgite

[0039] Take 5kg of attapulgite raw ore, break it into particles of about 10cm, add water 10 times its mass, add 50g of sodium hexametaphosphate, heat in a water bath at 60°C, stir for 30 minutes, and centrifugally filter the dispersed attapulgite slurry for later use .

[0040] 2. Surface activation of attapulgite

[0041] Add 1000ml of hydrochloric acid with a mass concentration of 10wt% to the filtered attapulgite, stir for 30 minutes, disperse ultrasonically for 5 minutes, then centrifuge at 200 rpm for 3 minutes, wash and dry the obtained wet solid to obtain solid powder, pass through an 80-mesh sieve for use .

[0042] 3. Material preforming

[0043] Mix 80 parts of activated and sieved attapulgite clay, 10 parts of DTCR, 3 parts of sodium bicarbonate, 3 parts of calcium silicate, and 4 parts of sodium-based concrete sealing and curing agent. , and then dry in the shade to a moisture content of 15%.

[0044] 4. Forming of rod-s...

Embodiment 2

[0047] 1. Purification of attapulgite

[0048] Take 5kg of attapulgite raw ore, break it into particles of about 10cm, add water 10 times its mass, add 50g of sodium hexametaphosphate, heat in a water bath at 60°C, stir for 30 minutes, and centrifugally filter the dispersed attapulgite slurry for later use .

[0049] 2. Surface modification of attapulgite

[0050] The purified attapulgite was reconfigured into an aqueous solution with a mass concentration of 5%, heated in a water bath at 80°C, stirred for 60 minutes, and the rotation speed was 500 rpm, and a modifier with a solid content of attapulgite of 1wt% was added. Alkyltrimethylammonium bromide was heated in a water bath at 80°C, stirred for 60 minutes at a speed of 500 rpm, and the obtained wet solid was washed and dried to obtain solid powder, which was passed through an 80-mesh sieve for use.

[0051] 3. Material preforming

[0052] Mix 80 parts of surface-modified attapulgite clay, 10 parts of DTCR, 3 parts of so...

Embodiment 3

[0056] 1. Purification of attapulgite and montmorillonite

[0057] 1. Purification of attapulgite

[0058] Take 5kg of attapulgite raw ore, break it into particles of about 10cm, add water 10 times its mass, add 50g of sodium hexametaphosphate, heat in a water bath at 60°C, stir for 30 minutes, and centrifugally filter the dispersed attapulgite slurry for later use .

[0059] Take 5kg of montmorillonite raw ore, break it into particles of about 10cm, add water 10 times its mass, add 50g of sodium hexametaphosphate, heat in a water bath at 60°C, stir for 30 minutes, and centrifugally filter the dispersed montmorillonite slurry for later use .

[0060] 2. Surface activation of attapulgite and montmorillonite

[0061] Add 1000ml of hydrochloric acid with a mass concentration of 10wt% into the filtered attapulgite, stir for 30 minutes, disperse ultrasonically for 5 minutes, then centrifuge at 200 rpm for 3 minutes, wash and dry the obtained wet solid to obtain solid powder, pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com