Electromagnetic shielding composite material and preparation method thereof

A composite material and electromagnetic shielding technology, which is applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems that the conductivity and electromagnetic shielding ability cannot be compared, and it is difficult to solve the oxidation resistance and settlement of metal fillers, etc., to achieve Reduce the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

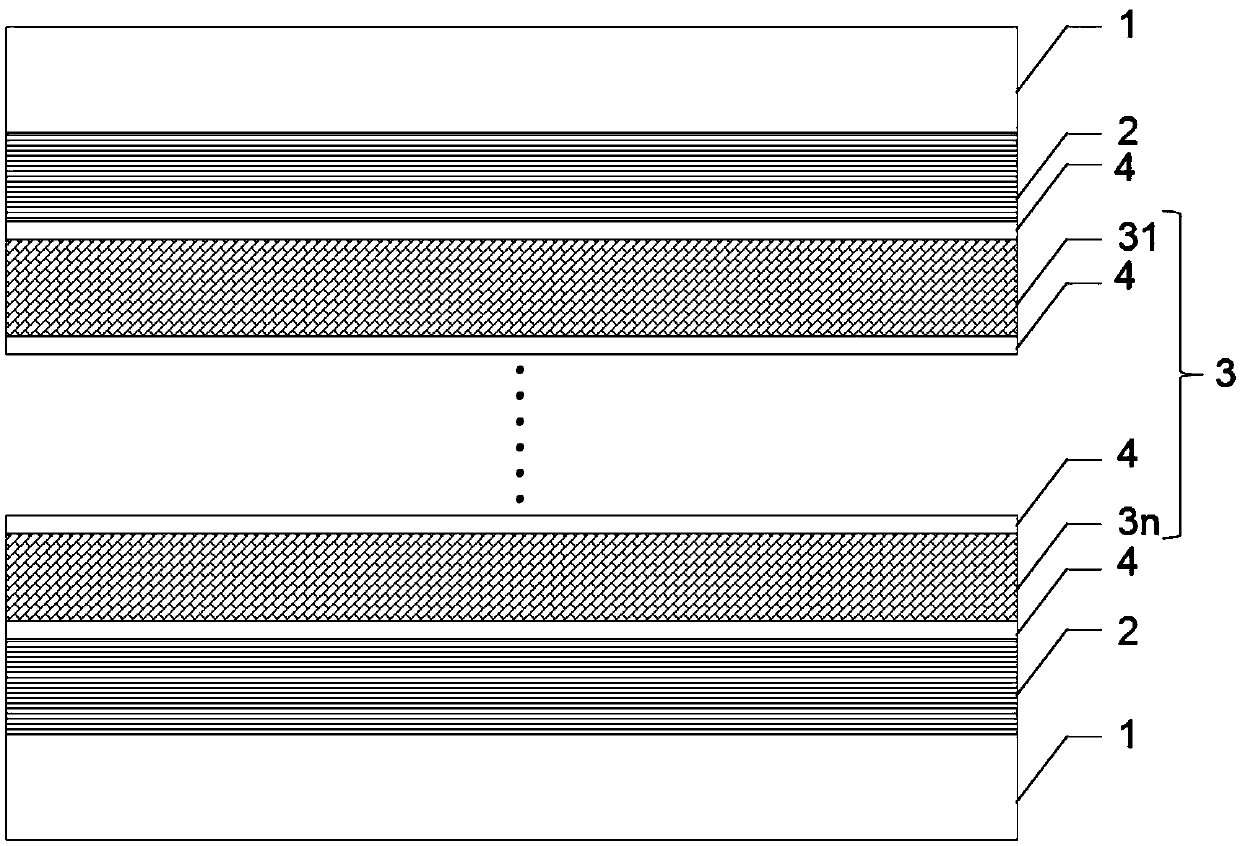

[0053] The present invention also proposes a preparation method of an electromagnetic shielding composite material, which includes the following steps:

[0054] 1) prepare absorbing paper and metallized glass fiber cloth;

[0055] 2) The absorbing paper and the metallized glass fiber cloth are coated with adhesive on both sides to obtain the absorbing paper prepreg and the metallized glass fiber cloth prepreg;

[0056] 3) In the hot-pressing mold coated with a release agent, lay resin, metal-plated glass fiber cloth prepreg, several layers of wave-absorbing paper prepreg with different absorbing agent contents, and metal-plated glass fiber cloth prepreg. Impregnated body and resin; wherein, the content of the absorbing agent in the absorbing paper is arranged from low to high or from high to low;

[0057] 4) Hot pressing forming: heat preservation and pressure holding, the reaction time is 2-3min / mm, determined according to the thickness of the electromagnetic shielding compo...

Embodiment 1-5

[0068] Mix silicon carbide fiber, carbon black, graphite and ultrafine nickel powder in a mass ratio of 3:1:1:1 to obtain a composite wave absorbing agent; mix it with aramid fiber and polyvinyl alcohol in a mass ratio of 70:25 :5 mixed to make absorbent paper. Prepare metal-plated fiber cloth according to the material type and requirements shown in table 1; the adhesive agent shown in table 1 is coated on both sides of described wave-absorbing paper and metal-plated glass fiber cloth, obtain wave-absorbing paper prepreg and Metallized glass fiber cloth prepreg; In a hot press mold coated with a release agent, resin, metallized glass fiber cloth prepreg, and absorbing paper with the content of absorber shown in Table 1 are laid in sequence And the number of layers, metal-coated glass fiber cloth prepreg and resin; keep the temperature at 160°C, and the pressure at 20MPa. The reaction time is determined according to the thickness of the pressed material, generally 2.5min / mm; ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com