Maltose functionalized nanometer composite material based on ion complementation type peptide self-assembly and preparation method and application of composite material

A nanocomposite material and nanomaterial technology, applied in the field of maltose functionalized nanocomposite materials, can solve problems such as strong surface dependence, cumbersome processing steps, and harsh conditions, and achieve simple preparation methods, environmentally friendly processes, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Synthesis of maltose-modified ion-complementary peptides

[0040] (1) Add 0.174g Fmoc-Rink Amide MBHA Resin into the solid-phase synthesis tube, add 5mL of dichloromethane to soak the resin for 30 minutes, fully swell, remove the dichloromethane by suction filtration, add 5mL of piperidine and N , The volume ratio of N-dimethylformamide is a mixed solution of 1:4, react for 20 minutes, remove the mixed solution by suction filtration, and then add 5 mL of piperidine and N,N-dimethylformamide with a volume ratio of 1: 4, reacted for 20 minutes, filtered with suction, washed the resin twice with dichloromethane, and washed the resin three times with N,N-dimethylformamide, 5 mL each time, to complete the Fmoc-Rink Amide MBHA Resin de-Fmoc-two Once, add 5mL N,N-dimethylformamide, 0.1331g Fmoc-Lys(Boc)-OH, 0.03837g 1-hydroxybenzotriazole, 0.1077g benzotriazole-N,N,N′ , N′-tetramethylurea tetrafluoroboric acid, 99 μL N,N′-diisopropylethylamine, stirred at room temperature ...

Embodiment 2

[0053] In this example, using C@Fe 3 o 4 Nanoparticles (prepared according to the method disclosed in the literature "Yang, J.; Li, J.; Qiao, J.; Lian, H.; Chen, H.J. Chromatogr. A 2014, 1325, 8-15") were replaced SiO in Example 1 2 @Fe 3 o 4 Nanoparticles, other steps are the same as in Example 1 to obtain maltose functionalized C@Fe 3 o 4 composite material.

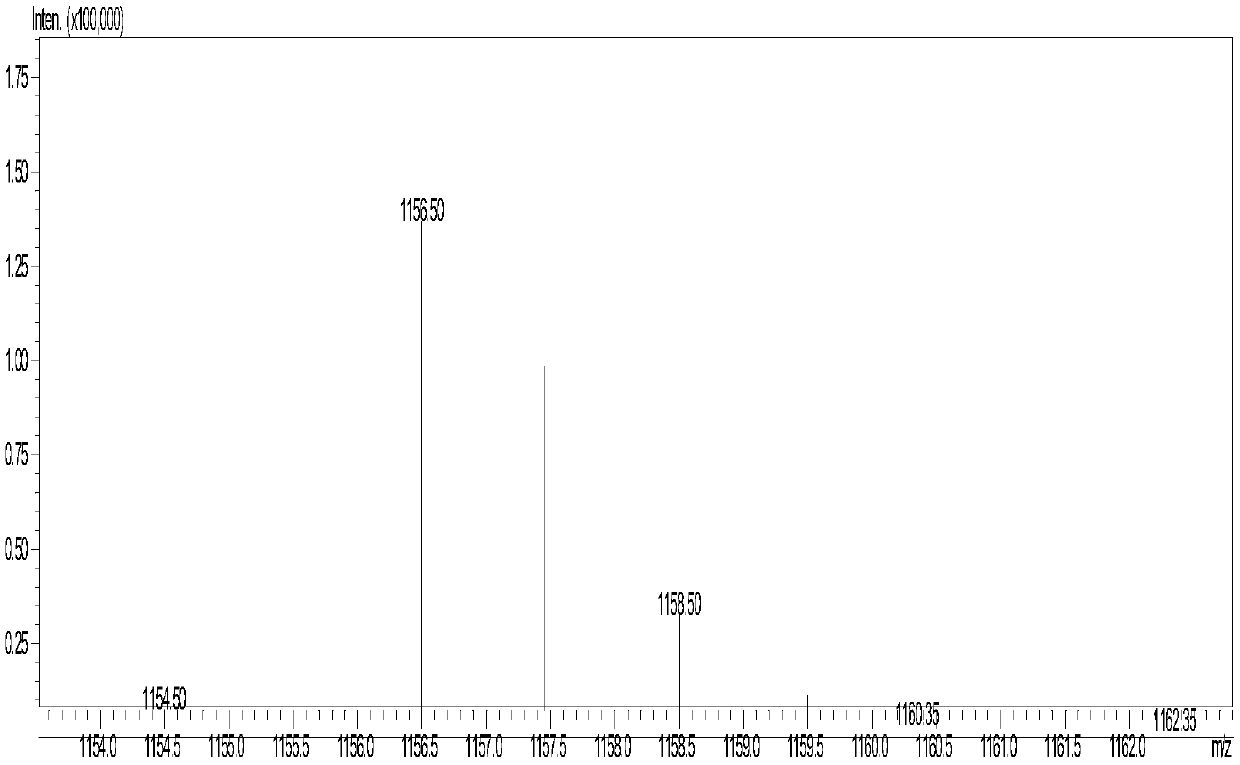

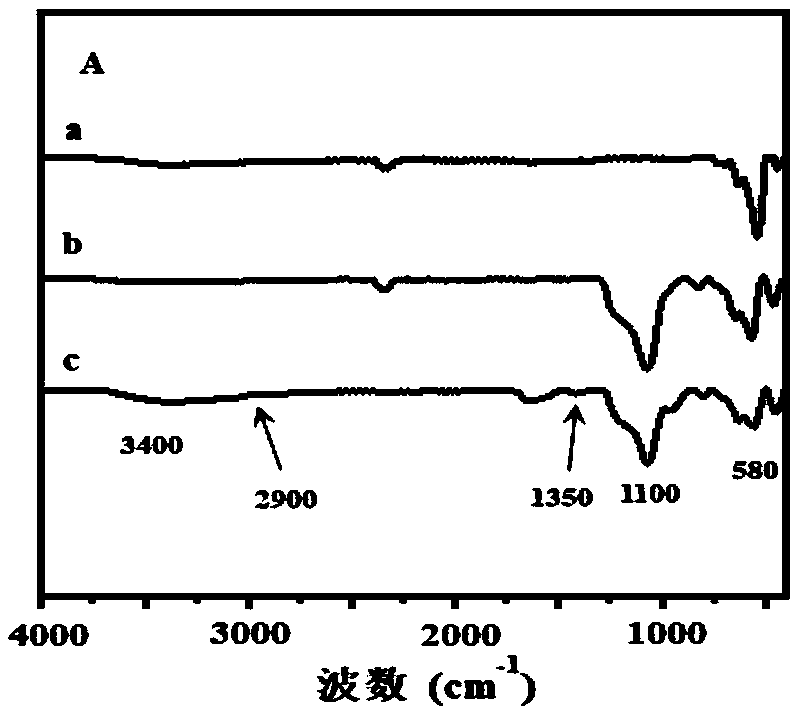

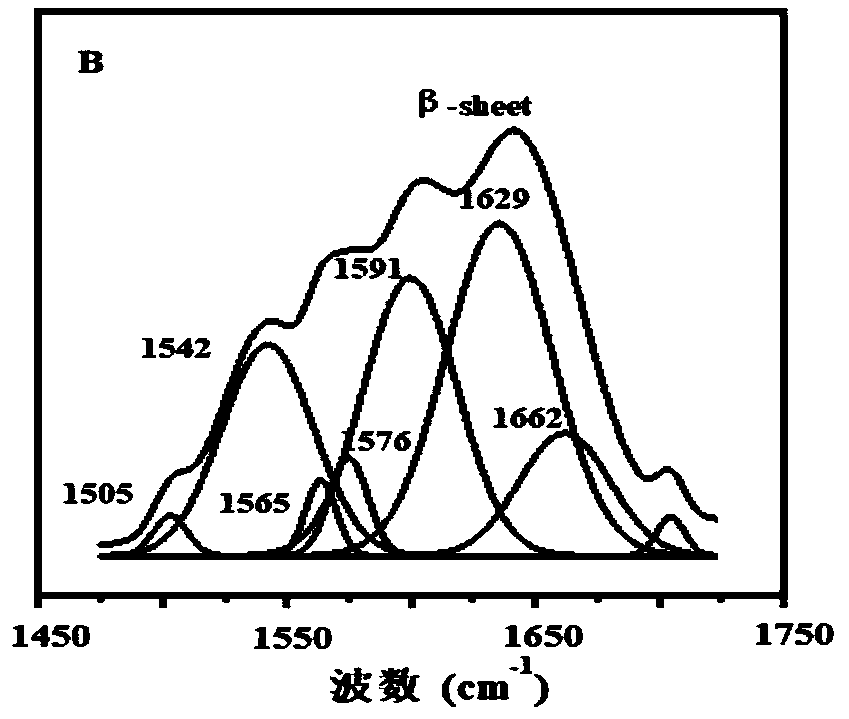

[0054] Fe in above-mentioned embodiment 1 and 2 3 o 4 , SiO 2 @Fe 3 o 4 、C@Fe 3 o 4 , maltose functionalized SiO 2 @Fe 3 o 4 Composite materials and maltose functionalized C@Fe 3 o 4 Composite materials were subjected to Fourier transform attenuated total reflection infrared spectroscopy and X-ray photoelectron spectroscopy. The results are as follows: Figure 2 ~ Figure 6 shown. It can be seen from the figure that maltose functionalized SiO 2 @Fe 3 o 4 Composite materials and maltose functionalized C@Fe 3 o 4 Composite material (580cm -1 At Fe-O, 1100cm -1 Si-O-Si at 1740 and 1620cm -1 C=O a...

Embodiment 3

[0056] Application of the maltose functionalized nanocomposite obtained in Examples 1 and 2 in glycopeptide enrichment

[0057] 1. Contrast experiments on the enrichment performance of different materials

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com