Antibacterial composite nanofiber membrane as well as preparation method and application thereof

A technology of composite nanofibers and nanofiber membranes, which is applied in the directions of fiber treatment, fiber chemical characteristics, biochemical fiber treatment, etc., can solve the problem that the filtration effect needs to be further improved, and achieves the effects of safety and environmental protection in the preparation process and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 0.1g of g-C was prepared by high-temperature calcination 3 N 4 The nanoparticles were added into 50ml of N,N-dimethylformamide (DMF) solvent, and then placed in an air plasma atmosphere for 120s, so that the nanoparticles were exfoliated into nanosheets with a particle size of 15nm. Then add the polyacrylonitrile polymer to be spun and stir until it is uniformly dispersed; the obtained polymer spinning solution is spun by electrospinning to obtain a 300 micron thick nanofiber film; Placed in a helium uniform glow discharge plasma atmosphere for 180s, then sprayed with g-C 3 N 4 The 0.1wt.% dispersion of nanosheets is sprayed for 20 seconds and dried at room temperature to obtain an antibacterial composite nanofiber membrane product.

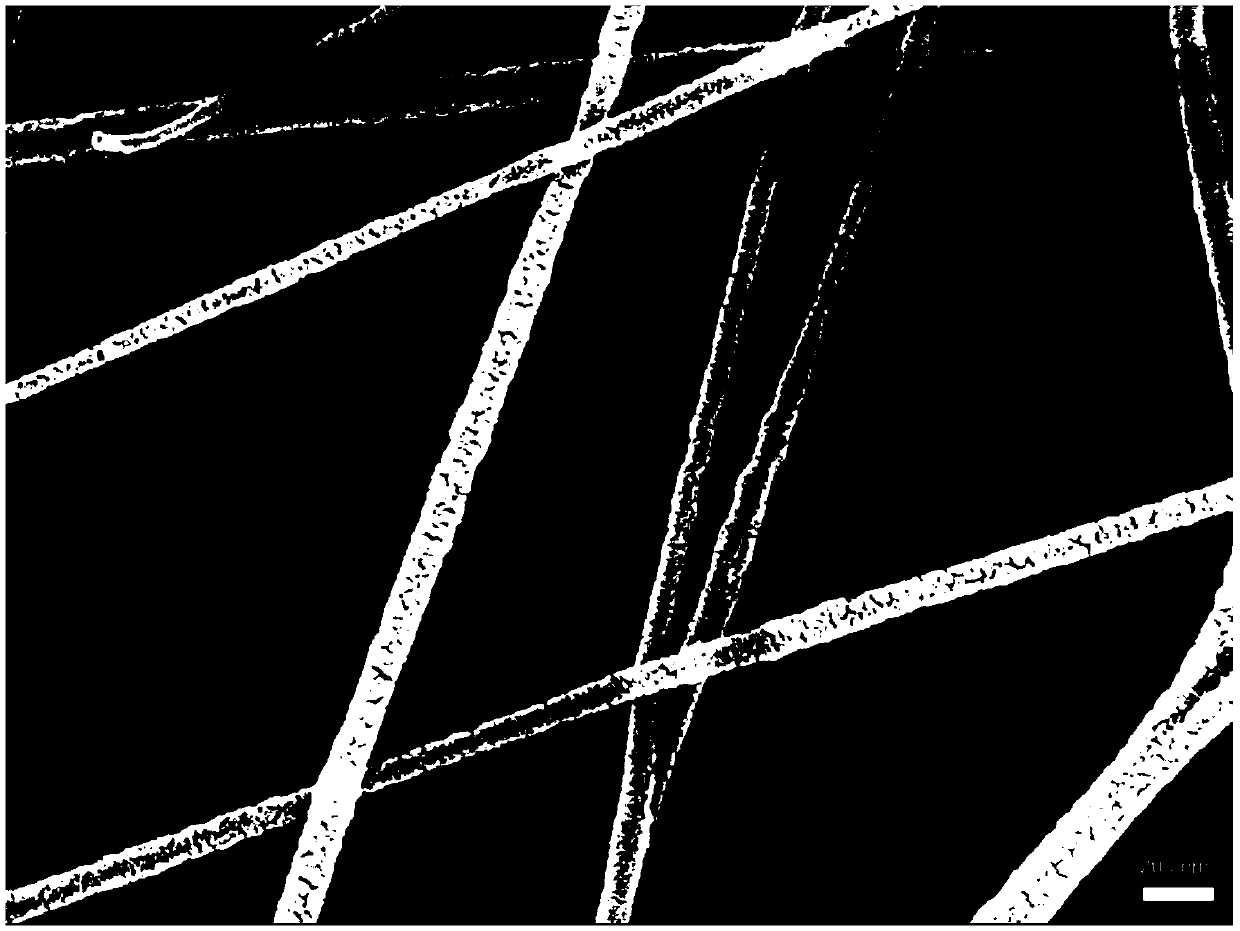

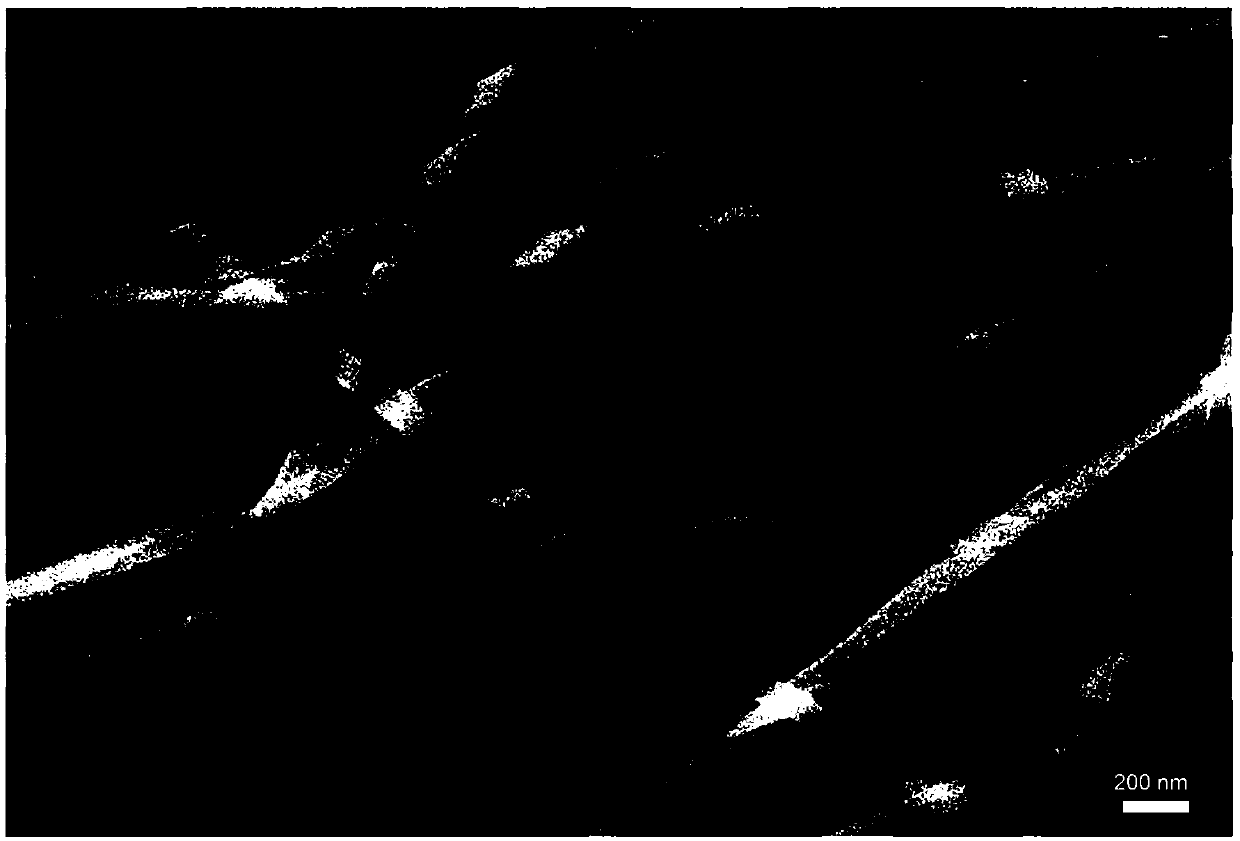

[0056] attached figure 1 Shown is the surface topography of the outer layer nanofibers in the antibacterial composite nanofiber membrane obtained in this embodiment. from figure 1It can be seen that the surface of the nanofiber has e...

Embodiment 2

[0059] 0.15g of g-C was prepared by high-temperature calcination 3 N 4 The nanoparticles were added into 60ml of formic acid solvent, and then placed in an argon plasma atmosphere for 90s, so that the nanoparticles were exfoliated into nanosheets with a particle size of 20nm. Then add the polyamide polymer to be spun and stir until it is uniformly dispersed; the resulting polymer spinning solution is spun by electrospinning to obtain a 450 micron thick nanofiber membrane; Treated in argon uniform glow discharge plasma atmosphere for 150s, then sprayed with g-C 3 N 4 0.2wt.% dispersion of nanosheets, sprayed for 30 seconds, and dried at room temperature to obtain an antibacterial composite nanofiber membrane product.

[0060] Utilize the common cigarette smoke filtration test method to test the filtration effect of the nanofiber membrane, and use a pressure gauge to measure the air flow pressure difference of the filter membrane. The results show that the fiber membrane prep...

Embodiment 3

[0062] 0.4g of g-C was prepared by high-temperature calcination 3 N 4 The nanoparticles were added into 100ml of deionized water solvent, and then placed in an oxygen plasma atmosphere for 300s, so that the nanoparticles were peeled off into nanosheets with a particle size of 30nm. Then add the polyvinyl alcohol polymer to be spun, and stir until it is uniformly dispersed; the obtained polymer spinning solution is spun by electrospinning to obtain a 500 micron thick nanofiber film; the obtained nanofiber film is again Placed in a nitrogen uniform glow discharge plasma atmosphere for 200s, then sprayed with g-C 3 N 4 The 0.5wt.% dispersion of nanosheets is sprayed for 15 seconds and dried at room temperature to obtain an antibacterial composite nanofiber film product.

[0063] Utilize the common cigarette smoke filtration test method to test the filtration effect of the nanofiber membrane, and use a pressure gauge to measure the air flow pressure difference of the filter mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com