Method for electrochemically preparing boron-containing polysilane

A polysilane, electrochemical technology, applied in electrolytic components, electrolytic process, electrolytic organic production, etc., can solve the problems of high synthesis cost, low ceramic yield, high raw material price, etc., and achieve high ceramic conversion rate and mild reaction conditions. , the effect of low price of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

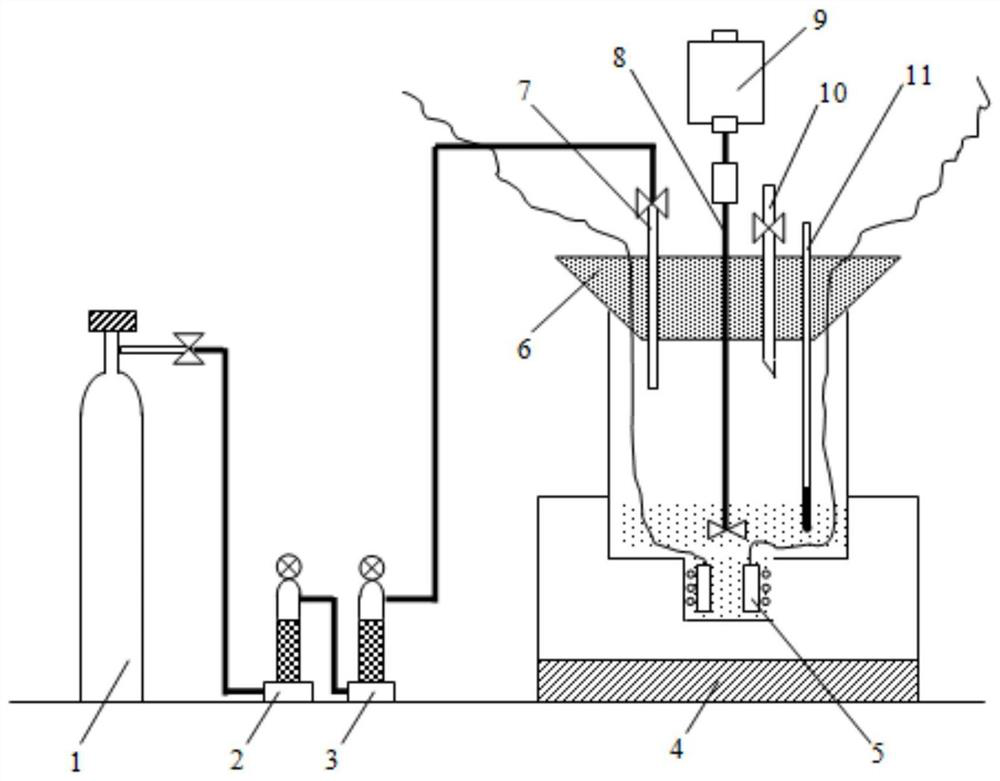

[0028] In this example, see figure 1 , using an electrochemical reaction setup, including N 2 Gas cylinder 1, drying tower as molecular sieve 2, calcium chloride drying tower 3, ultrasonic equipment 4, magnesium electrode 5, rubber stopper 6, ventilation pipe 7, stirring rod 8, motor 9, feeding pipe 10, thermometer 11 and electrodes wire. Utilize the rubber stopper 6 to seal the electrochemical reaction bottle, the ventilation pipe 7, the stirring rod 8, the feed pipe 10, the thermometer 11, and the electrode wire are respectively installed and set through the rubber stopper 6, and the motor 9 is used to drive the 8 pairs of stirring rods The solution in the electrochemical reaction bottle is stirred, and the ultrasonic device 4 ultrasonically stirs the solution in the electrochemical reaction bottle, and the magnesium electrode 5 is immersed in the solution in the electrochemical reaction bottle made of metal magnesium, and the vent tube 7 is made of N 2 Cylinder 1 as gas s...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, especially in that:

[0040] In this embodiment, using the electrochemical reaction device of this embodiment, a method for electrochemically preparing boron-containing polysilane, using trihalosilane, allyl chloride, and sodium borohydride as raw materials, wherein trihalosilane, allyl The molar ratio of base chloride to sodium borohydride is 3:1:1, tetrahydrofuran is used as solvent, lithium perchlorate is used as electrolyte, metal magnesium material is used as electrode, and it is obtained by electrochemical reaction under a periodically reversing DC electric field. Boron-containing polysilane comprises the steps of:

[0041] a. Add 0.15 mol propyltrichlorosilane and 0.05 mol allyl chloride into the electrochemical reverse bottle equipped with vent tube and stirring rod 8, and add sodium dehydration to the electrochemical reverse bottle at the same time, and distill to obtain the 66 °C fraction Treated 130ml te...

Embodiment 3

[0048] This embodiment is basically the same as the previous embodiment, and the special features are:

[0049] In this embodiment, using the electrochemical reaction device of this embodiment, a method for electrochemically preparing boron-containing polysilane, using trihalosilane, allyl chloride, and sodium borohydride as raw materials, wherein trihalosilane, allyl The molar ratio of base chloride to sodium borohydride is 3:1:1, tetrahydrofuran is used as solvent, lithium perchlorate is used as electrolyte, metal magnesium material is used as electrode, and it is obtained by electrochemical reaction under a periodically reversing DC electric field. Boron-containing polysilane comprises the steps of:

[0050] a. Add 0.15mol of phenyltrichlorosilane and 0.05mol of allyl chloride into the electrochemical inversion bottle equipped with vent tube and stirring rod 8, at the same time, add sodium dehydration to the electrochemical inversion bottle, and distill the 66°C fraction T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com