Polyimide/nanofiber composite paper and preparation method thereof

A technology of polyimide and nanofibers, which is applied in fiber treatment, synthetic cellulose/non-cellulose material pulp/paper, non-fiber pulp addition, etc., can solve the problems that cannot meet the needs of high-performance lithium-ion batteries and electrospinning Low efficiency, low porosity and other problems, to achieve the effect of good mechanical properties, small pore size, high liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037]According to a preferred embodiment of the present invention, the preparation method of the polyimide / nanofiber composite paper comprises:

[0038] (1) Disperse PI chopped fibers in a standard fiber disintegrator, add polyethylene oxide (PEO) solution to obtain a uniformly dispersed slurry;

[0039] (2) the slurry of step (1) is copied into fiber paper by a sheet former, and dried;

[0040] (3) impregnating the fiber paper obtained in step (2) with the first polyamic acid solution, and drying at 40-100°C;

[0041] (4) on both sides of the fiber paper in step (3), the second polyamic acid solution is used to carry out electrospinning respectively;

[0042] (5) The film material obtained in step (4) is hot-pressed and cross-linked, and hot-pressed at a temperature of 200-350 ° C and a pressure of 0-5 MPa to obtain a polyimide / nanofiber with PI fiber paper as a skeleton Composite paper.

[0043] Compared with the prior art, the above-mentioned preferred embodiment has th...

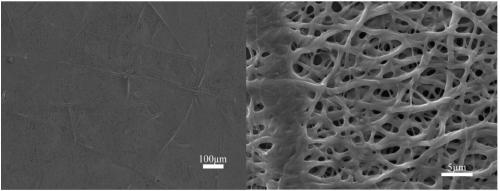

Embodiment 1

[0053] (1) Get 0.314g polyimide chopped fiber (diameter is 8 μm, length is 4mm, tensile strength is 3.0GPa, modulus is 110GPa, elongation is 3%), disperse in standard fiber disintegrator , adding a polyethylene oxide solution with a mass fraction of 1% to obtain a uniformly dispersed slurry;

[0054] (2) the slurry of step (1) is copied into fiber paper by a sheet former, and dried;

[0055] (3) Dissolve 4,4-diaminodiphenyl ether (ODA) in the solvent of N,N-dimethylformamide (DMF). After the ODA is completely dissolved, add 4,4 '-Diphenyl ether dianhydride (ODPA), control the molar ratio of ODA to ODPA to 1:1.01, stir at 10°C for 120 minutes to generate a polyamic acid product. Dilute the polyamic acid solution to a solid content of 1% by weight and a viscosity of 25cp, impregnate the fiber paper obtained in step (2), and dry at 80°C;

[0056] (4) Electrospinning is performed on both sides of the fiber paper in step (3) using polyamic acid solution to form fibers with a diam...

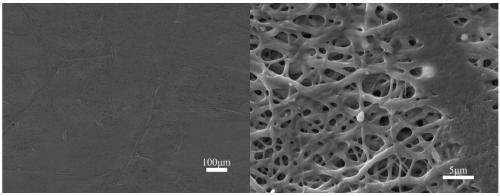

Embodiment 2

[0059] (1) Get 0.314g polyimide fiber (diameter is 8 μm, length is 4mm, tensile strength is 3.0GPa, modulus is 110GPa, elongation is 3%), disperses in standard fiber disintegrator, Add a polyethylene oxide solution with a mass fraction of 1% to obtain a uniformly dispersed slurry;

[0060] (2) the slurry of step (1) is copied into fiber paper by a sheet former, and dried;

[0061] (3) Dissolve 4,4-diaminodiphenyl ether (ODA) in the solvent of N,N-dimethylformamide (DMF). After the ODA is completely dissolved, add 4,4 '-Diphenyl ether dianhydride (ODPA), control the molar ratio of ODA to ODPA to 1:1.01, stir at 10°C for 120 minutes to generate a polyamic acid product. Dilute the polyamic acid solution to a solid content of 1% by weight and a viscosity of 25cp, impregnate the fiber paper obtained in step (2), and dry at 80°C;

[0062] (4) Electrospinning is performed on both sides of the fiber paper in step (3) using polyamic acid solution to form fibers with a diameter of 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com