A kind of synthetic method of nano zsm-5 molecular sieve aggregate

A technology of ZSM-5 and synthetic method, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low recovery rate of fine particles, unconventional, complicated separation and treatment process, etc. Achieve the effect of reducing operation and processing costs, reducing processing costs, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

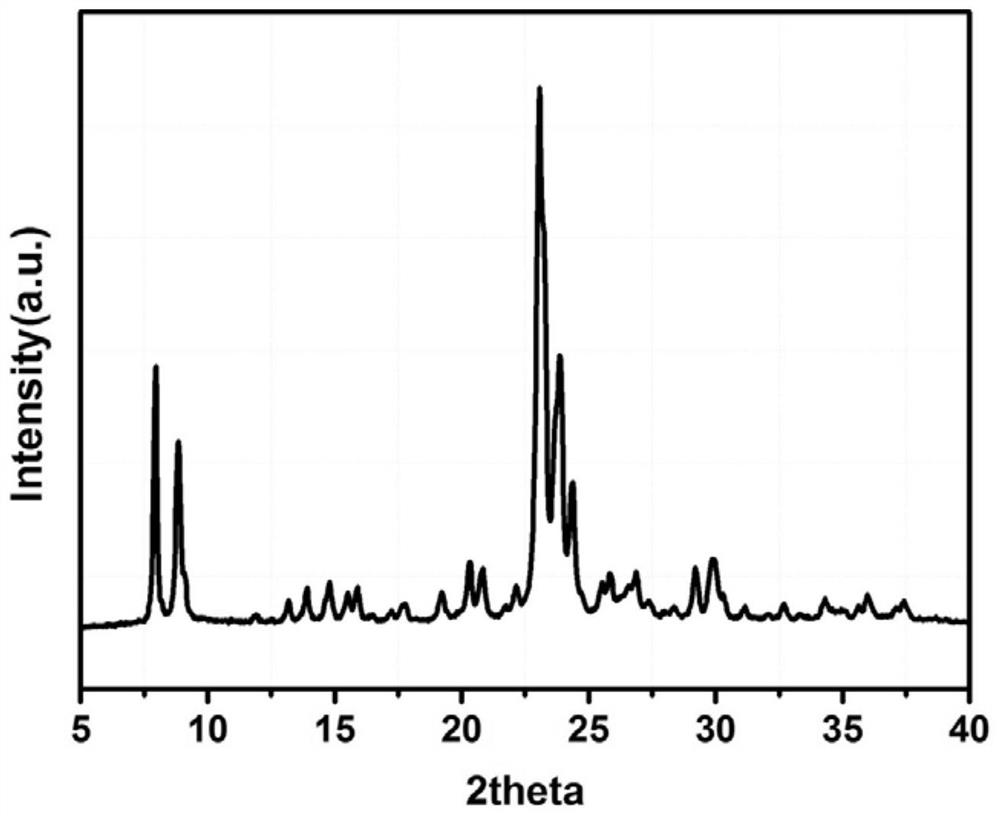

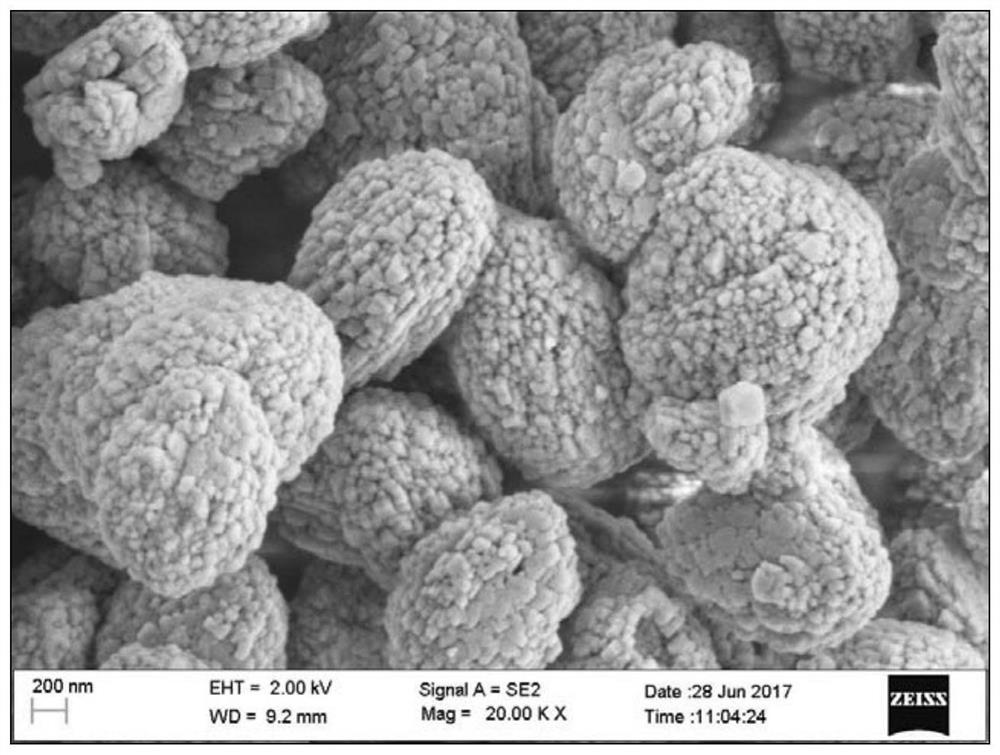

[0046] 1) mixing the acidified aluminum source solution and the alkaline silicon source solution to obtain the mother liquor of the molecular sieve; the acidified aluminum source solution includes aluminum sulfate, water and sulfuric acid; the alkaline silicon source solution includes water glass (modulus 3.2 ~3.4), water, n-butylamine, and nano-aggregate all-silicon molecular sieve seed crystals that have only undergone low-temperature drying treatment, the particle size is no more than 200nm, and the morphology is an aggregated state formed by the accumulation of primary particles of 10-30nm; in the molecular sieve mother liquor , Na 2 O: Al 2 o 3 : SiO 2 :H 2 O: n-butylamine molar ratio is 0.20:0.04:1:50:0.32; 2 5% by weight;

[0047] 2) After the molecular sieve mother liquor was ultrasonically oscillated at 50kHz for 0.5 hours, the mixed solution was transferred to a 5L autoclave for hydrothermal stirring and crystallization. The hydrothermal crystallization was divi...

Embodiment 2

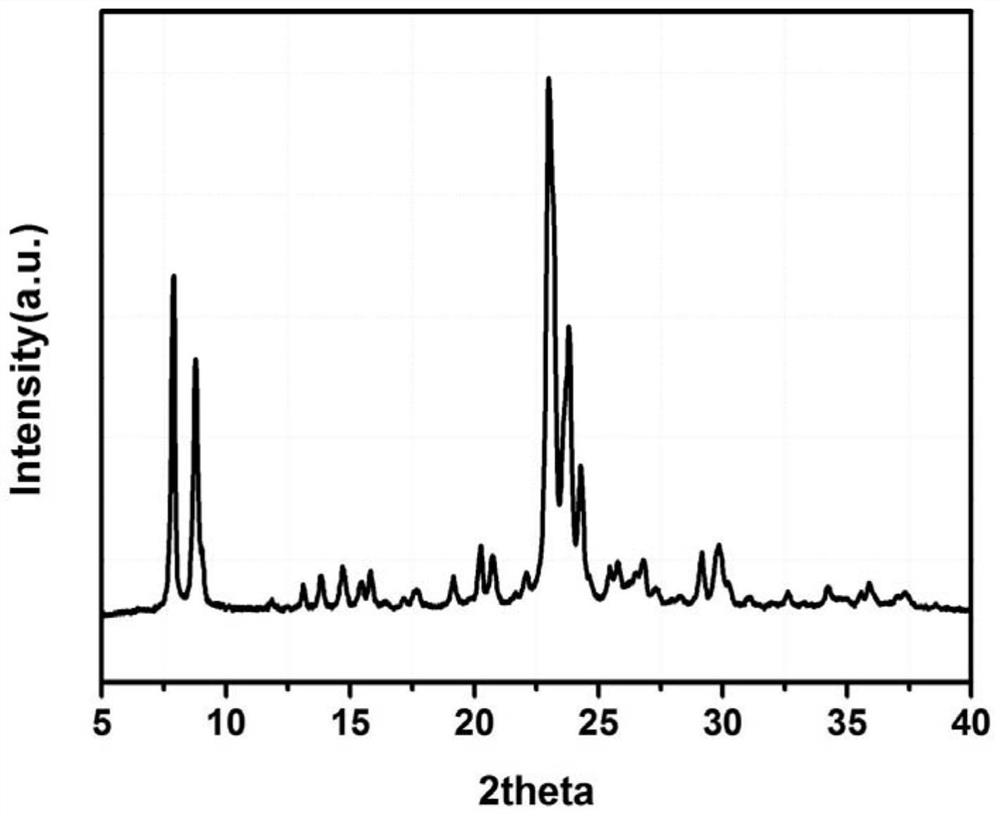

[0049] 1) mixing an acidified aluminum source solution and an alkaline silicon source solution to obtain a molecular sieve mother liquor; the acidified aluminum source solution includes aluminum nitrate, water and sulfuric acid; the alkaline silicon source solution includes solid sodium silicate powder, Water, ethylenediamine, and nano-aggregate all-silicon molecular sieve seed crystals that have only undergone low-temperature drying treatment, the particle size does not exceed 200nm, and the appearance is an aggregated state formed by the accumulation of primary particles of 10-30nm; in the molecular sieve mother liquor, Na 2 O: Al 2 o 3 : SiO 2 :H 2 The molar ratio of O: ethylenediamine is 0.18:0.04:1:50:0.32; nano-aggregate all-silicon molecular sieve seeds account for SiO 2 5% by weight;

[0050] 2) After the molecular sieve mother liquor was ultrasonically oscillated at 50kHz for 2.0 hours, the mixed solution was transferred to a 5L autoclave for hydrothermal stirring...

Embodiment 3

[0052] 1) mixing the acidified aluminum source solution and the alkaline silicon source solution to obtain the molecular sieve mother liquor; the acidified aluminum source solution includes aluminum chloride, water and hydrochloric acid; the alkaline silicon source solution includes water glass (modulus 3.2-3.4), water, n-propylamine, and nano-aggregate all-silicon molecular sieve seed crystals that have only been dried at low temperature. , Na 2 O: Al 2 o 3 : SiO 2 :H 2 O: n-propylamine molar ratio is 0.20:0.05:1:40:0.32; 2 7% by weight;

[0053] 2) After the molecular sieve mother liquor was ultrasonically oscillated at 50kHz for 5 hours, the mixed solution was transferred to a 5L autoclave for hydrothermal stirring and crystallization. The hydrothermal crystallization was divided into two stages, and the hydrothermal crystallization temperature of the first stage was The crystallization time at 100°C is 24 hours, and the hydrothermal crystallization temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com