Chitin-based biomass charcoal double-sided electrode slice for electroadsorption and preparation method thereof

A technology of biomass charcoal and chitin, applied in separation methods, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low adsorption efficiency, complex process, uneven distribution of electrode materials, etc. The effect of improved efficiency, simple production process and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, which is not intended to limit its protection scope.

[0026] In order to avoid repetition, the technical parameters involved in this specific embodiment are first described in a unified manner as follows, and will not be repeated in the embodiments:

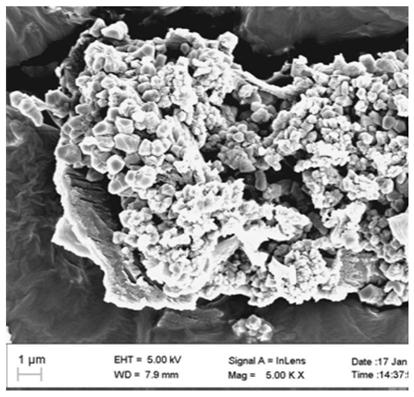

[0027] The purity of the chitin powder is more than or equal to 95%, and the particle diameter of the chitin powder is less than 0.05mm.

[0028] The purity of the potassium hydroxide powder is more than or equal to 99%; the particle diameter of the potassium hydroxide powder is less than 0.1mm.

[0029] The purity of the polyvinylidene fluoride powder is ≥99.5%, and the particle diameter of the polyvinylidene fluoride powder is <0.1mm.

[0030] The average thickness of the coated coating is 0.25-0.3 mm.

[0031] Implementation 1

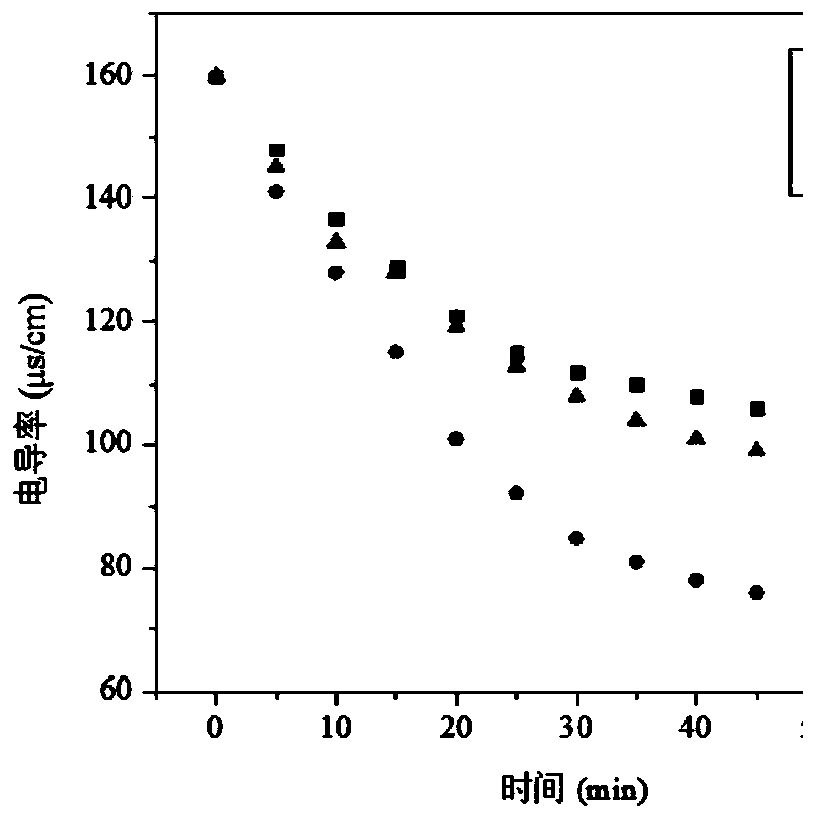

[0032] A chitin-based biochar double-sided electrode sheet for e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com