Preparation method of organic small molecule crystal patterned array

A technology of crystal patterns and small molecules, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of complicated etching steps, high price, human body damage by fluorinated etching plasma, etc., and achieve the growth method Simple, easy to design, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Carry out the preparation method of photoresist template as described in technical scheme 1.1:

[0060] 1.1 Preparation of photoresist template:

[0061] 1.1.1 Spin coating: Spin a layer of SU-8 2015 photoresist on a clean silicon wafer (cleaned by standard RCA method) with a homogenizer, the speed of the homogenizer is 7000rpm, and the thickness of the photoresist layer is 6μm;

[0062] 1.1.2 Pre-baking: Carry out pre-baking treatment on the glue baking machine, so that the photoresist is thermally cured, the baking temperature is 95 ° C, and the baking time is 2 minutes;

[0063] 1.1.3 UV exposure: Use a UV lithography machine to expose the photoresist film through the mask and control the exposure dose. The exposure dose is 100mJ / cm 2 ;

[0064] 1.1.4 Post-baking: Carry out post-baking treatment on the glue baking machine to form the patterned structure. The baking temperature is 95°C and the baking time is 3.5 minutes;

[0065] 1.1.5 Developing: use the photoresi...

Embodiment 2

[0070] Carry out patterned growth of organic small molecule crystals according to the method described in technical scheme 1.2:

[0071] 1.2 Patterned growth of small organic molecule crystals:

[0072] 1.2.1 Prepare a toluene solution of TIPS-pentacene with a concentration of 1.5 mg / ml;

[0073] 1.2.2 Capillary force printing method of "sandwich" structure system: 5 μl of solution is added dropwise on the photoresist template prepared in Example 1, and the OTS (octadecyltrichlorosilane) modified silica substrate Cover the top of the photoresist template and fix it with a long tail clip to form a sandwich structure. Under the joint action of template induction and capillary force, a TIPS-pentacene crystal patterned structure can be directly generated on the target substrate.

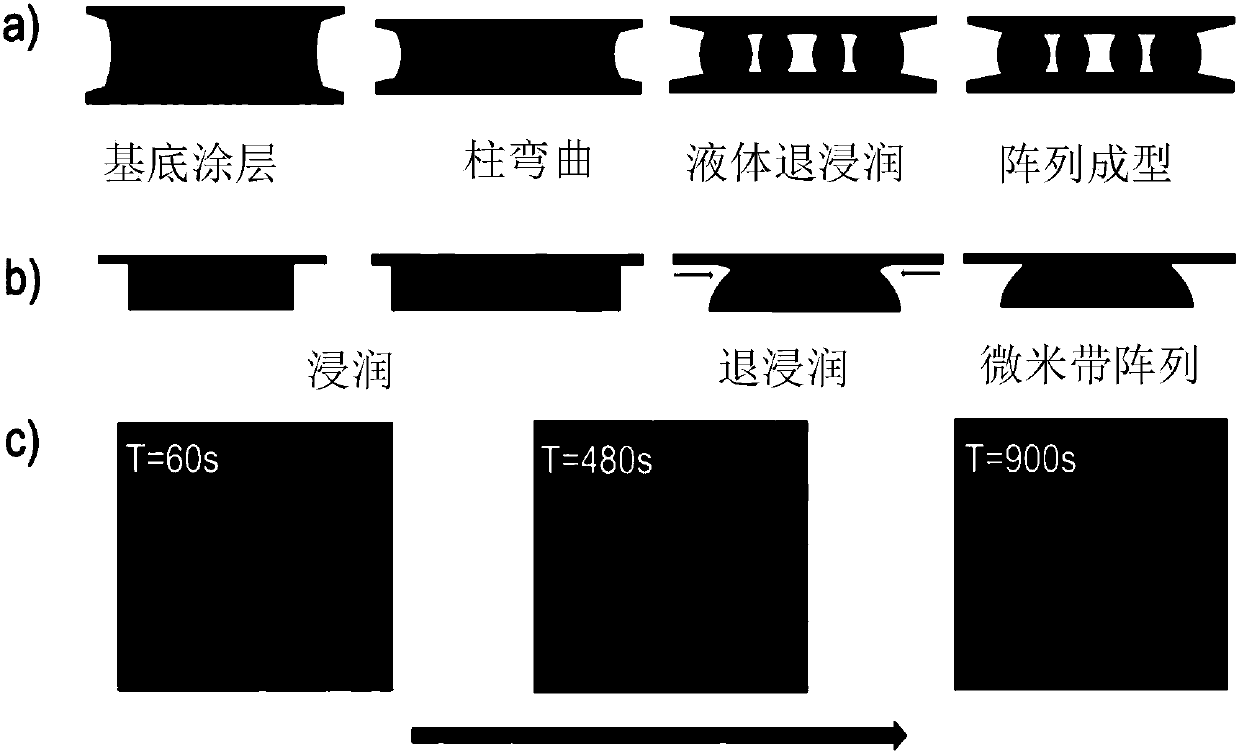

[0074] Experimental results: if image 3 Shown is the growth schematic diagram of the "sandwich" system and the actual fluorescence monitoring image. It can be found that under the induction of the pho...

Embodiment 3

[0076] On the basis of Example 2, by adjusting the concentration of the solution, a size-adjustable pentacene (TIPS-pentacene) microribbon array can be obtained.

[0077] 1.2 Patterned growth of small organic molecule crystals:

[0078] 1.2.1 Prepare a toluene solution of TIPS-pentacene with a concentration of 0.3-1.5mg / ml;

[0079] 1.2.2 Capillary force printing method of "sandwich" structure system: 5 μl of solution is added dropwise on the photoresist template prepared in Example 1, and the OTS (octadecyltrichlorosilane) modified silica substrate Cover the top of the photoresist template and fix it with a long tail clip to form a sandwich structure. Under the joint action of template induction and capillary force, a TIPS-pentacene crystal patterned structure can be directly generated on the target substrate.

[0080] Experimental results: if Figure 5 As shown, by adjusting the growth concentration of the reaction solution, a size-adjustable microribbon array can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com