Shape memory-type bioactive nano particle/biodegradable polyester composite multi-scale pore biological scaffold and preparation method thereof

A nanoparticle and biologically active technology, applied in the field of biomedical materials, can solve the problems of not having hydroxyapatite and shape memory type, and achieve the effect of large application and promotion value, low production cost and excellent dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

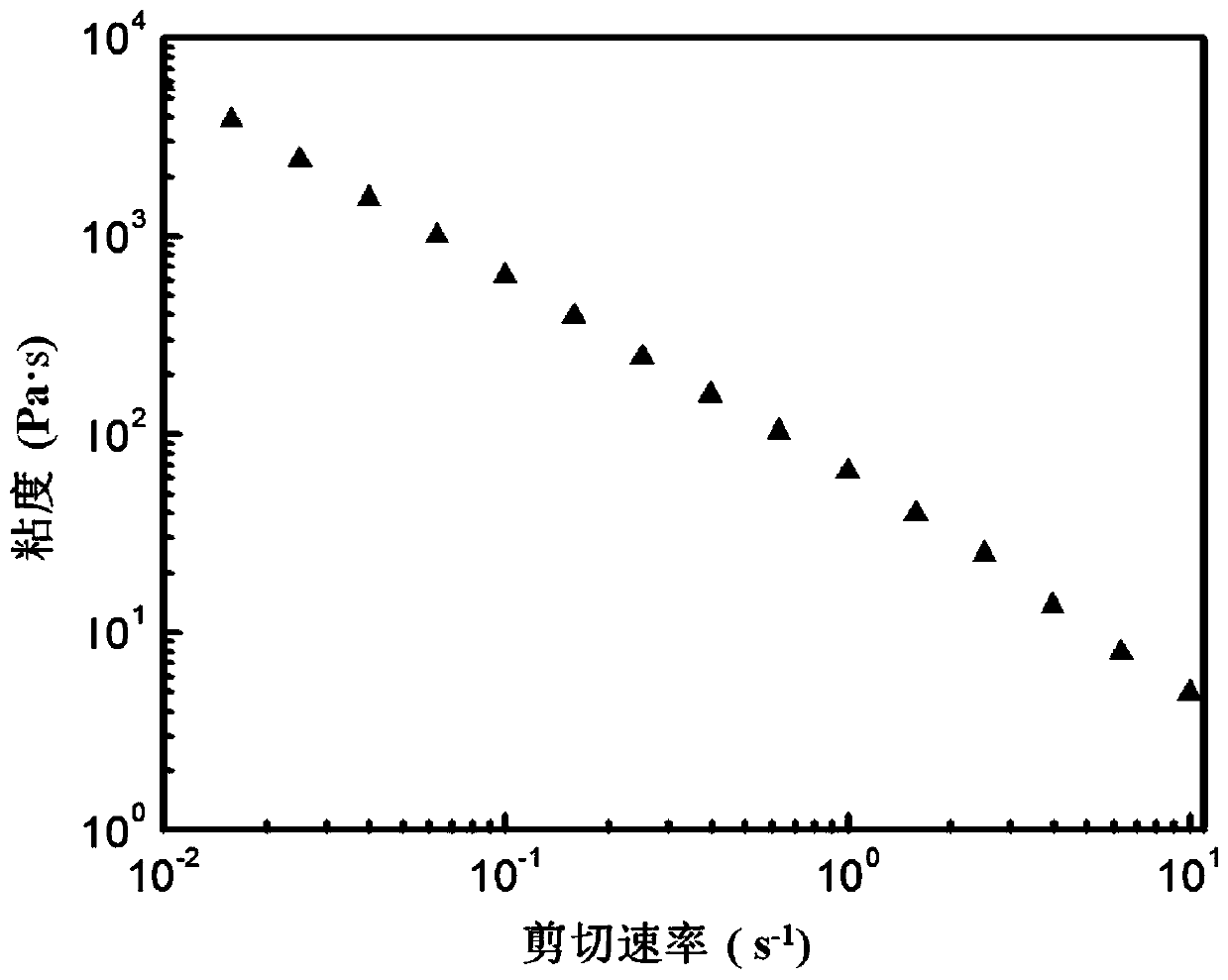

Method used

Image

Examples

Embodiment 1

[0054] (1) In an ice-water bath, prepare 4 parts by volume of dichloromethane suspension by ultrasonication for 30 minutes, that is, the oil phase, in which the biodegradable polylactic acid-trimethylene carbonate copolymer (molecular weight is 5.2 × 10 4 g / mol, wherein the molar ratio of lactic acid and trimethylene carbonate is 80:20), the mass volume fraction of hydrophobic hydroxyapatite and hydrophobic nano silicon dioxide is 9w / v%, 7.5w / v%, 2w / v%;

[0055] (2) Add 12 parts by volume of distilled water in batches to the oil phase obtained in step (1), mix and emulsify with a vortex mixer at 3000r / min for 12min to obtain a water-in-oil type high internal phase emulsion;

[0056] (3) Use the high internal phase emulsion obtained in step (2) as ink, put it into the extrusion 3D printer syringe equipped with 18G micro-needles, and apply pressure to the syringe with a pressure of 0.05MPa air pump to control the printing speed 20mm / s, according to the preset rectangular parall...

Embodiment 2

[0060] (1) In an ice-water bath, prepare 4 parts by volume of dichloromethane suspension, that is, the oil phase, by ultrasonication for 30 minutes, wherein the biodegradable polylactic acid-trimethylene carbonate copolymer (molecular weight is 5 × 10 4 g / mol, wherein the molar ratio of lactic acid and trimethylene carbonate is 70:30), the mass volume fraction of hydrophobic hydroxyapatite and hydrophobic nano silicon dioxide is 9w / v%, 9w / v%, 1w / v%;

[0061] (2) Add 13 parts by volume of distilled water in batches to the oil phase obtained in step (1), mix and emulsify with a vortex mixer at 2500r / min for 15min to obtain a water-in-oil type high internal phase emulsion;

[0062] (3) Use the high internal phase emulsion obtained in step (2) as ink, put it into the extrusion 3D printer syringe equipped with 20G micro-needles, and apply pressure to the syringe with a pressure of 0.02MPa air pump to control the printing speed 20mm / s, according to the preset cylindrical (Φ30mm×7m...

Embodiment 3

[0065] (1) In an ice-water bath, prepare 4 parts by volume of dichloromethane suspension by ultrasonication for 30 minutes, that is, the oil phase, in which the biodegradable polylactic acid-glycolic acid-trimethylene carbonate copolymer (molecular weight is 3× 10 4 g / mol, wherein the molar ratio of lactic acid, glycolic acid and trimethylene carbonate is 80:10:10), the mass volume fraction of hydrophobic hydroxyapatite and ethyl cellulose is 4w / v%, 9w / v %, 2w / v%;

[0066] (2) Add 12 parts by volume of distilled water in batches to the oil phase obtained in step (1), mix and emulsify with a vortex mixer at 2500r / min for 15 minutes to obtain a water-in-oil type high internal phase emulsion;

[0067] (3) Use the high internal phase emulsion obtained in step (2) as ink, put it into an extrusion 3D printer syringe equipped with a 21G microneedle, and use a 0.04MPa air pump to apply pressure to the syringe to control the printing speed 25mm / s, according to the preset scaffold cub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Mass volume fraction | aaaaa | aaaaa |

| Mass volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com